Composite yarn with non-destructive consolidation layered net powder-coated particles and its preparation method and device

A technology for preparing a device and a layered net, applied in the direction of continuous winding spinning machine, yarn, spinning machine, etc., can solve the problems of leakage of powder particles, crushing damage of particulate materials, loss of particles, etc., to ensure softness degree, the effect of solving damage and powder leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

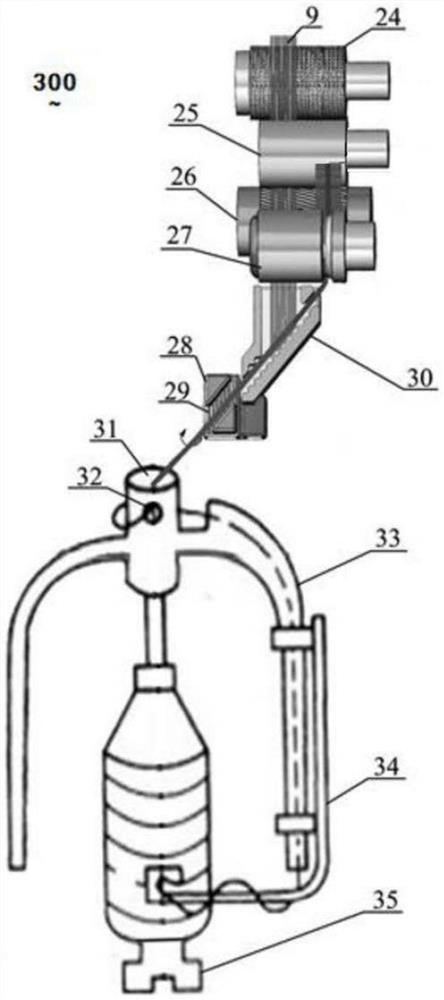

[0068] The invention provides a method for preparing a composite yarn of non-destructive consolidation layered mesh-coated powder particles, which is prepared by using the above-mentioned preparation device, including the following steps:

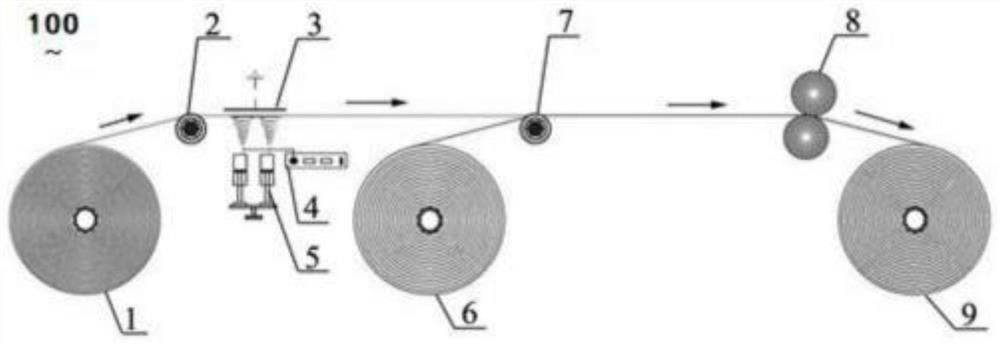

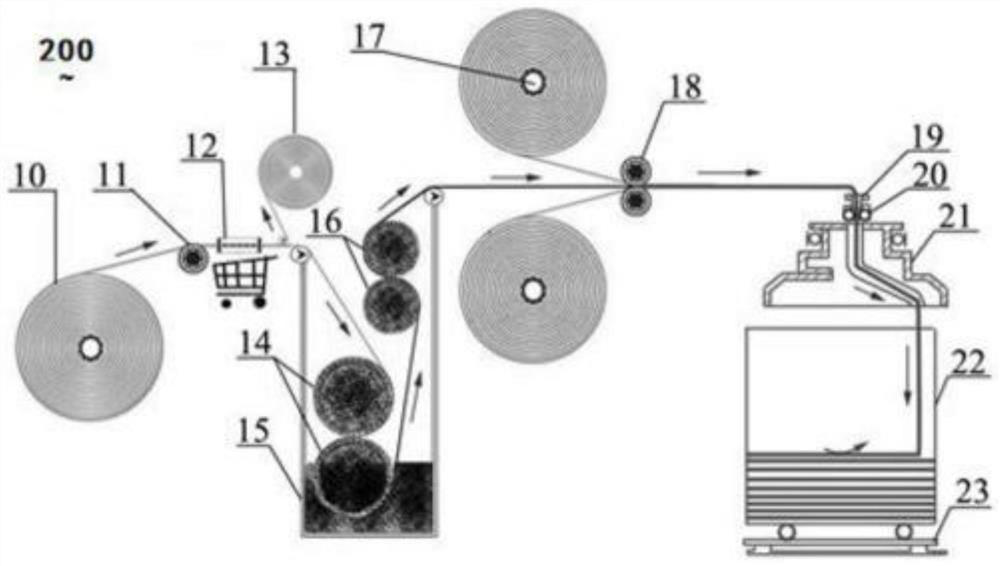

[0069] S1, the preparation of the nano-micro composite leak-proof strip: (prepared by using the leak-proof strip preparation device 100)

[0070] The nano-air filter membrane strip unwound from the air filter membrane strip package 1 is run to the electrostatic spinning area through the threaded film spreading roller 2, and the nano-spinning liquid is injected into the nano-electrostatic spinneret 5 through the metering pump 4 , under the high-voltage electrostatic action between the nano-electrostatic spinneret 5 and the receiving plate 3, the adhesive nanofibers are continuously ejected from the nano-electrostatic spinneret 5 (the ejected nanofibers have static electricity and viscosity, strong adhesion) to the moving nanometer air filter...

Embodiment 1

[0078] see Figure 4 As shown, Example 1 of the present invention provides a method for preparing a non-destructive consolidation type obliquely coated carbon microsphere high wear-resistant and high-adsorption composite yarn, which is prepared by using the above-mentioned device, including the following steps:

[0079] PP melt-blown non-woven fabric is selected as the air filter membrane strip, and PP spunbonded non-woven fabric is used as the conventional micron fiber non-woven fabric. After step S1, it is combined with PVB electrospun nanofibers to prepare a nanofiber with a width of 20 mm. Micro-composite leak-proof strip.

[0080] Select an adhesive tape with a width of 4 mm, and through step S2, the adhesive tape is hollowed out into a circular hole with a Sierpinski triangle shape, and a large number of nanoporous microspheres with a particle size of 500 microns are adhered. The width of the microfiber non-woven fabric strip is 20 mm, and the width of the notch of the ...

Embodiment 2

[0087] see Figure 5 As shown, the preparation method of the light-weight wear-resistant and warm-keeping composite yarn provided by the embodiment 2 of the present invention, which is non-destructively consolidated and obliquely coated with polystyrene microspheres, is prepared by using the above-mentioned device, including the following steps:

[0088] Polyurethane air filter membrane strips are selected, and through step S1, nylon 6 electrospun nanofibers are combined with nylon 6 non-woven fabric strips to prepare a nano-micro-composite leak-proof strip with a width of 8 mm.

[0089] Select an adhesive tape with a width of 6 mm, and through step S2, the adhesive tape is hollowed out into randomly distributed circular holes, a large number of polystyrene foam balls with a particle size of 1 mm are adhered, and the upper and lower nanofiber non-woven The width of the cloth strip is 12 mm, and the width of the notch of the annular groove is 1 / 2 of the width of the net-covered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com