Lithium battery anode material and preparation method thereof

A positive electrode material, lithium battery technology, applied in the direction of battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of high surface resistance, poor peel strength, poor contact, etc., and achieve excellent cycle performance, good safety performance, Excellent effect of high temperature cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

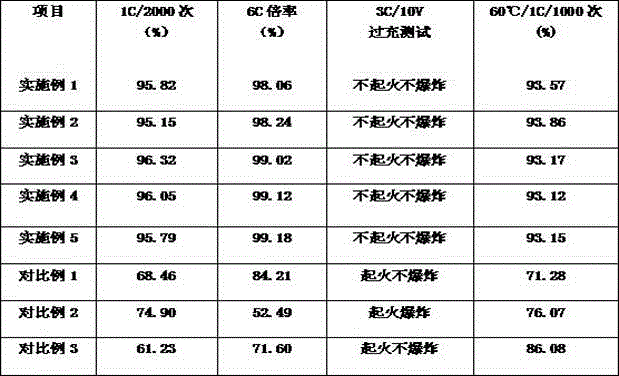

Examples

Embodiment 1

[0016] A lithium battery cathode material, the main raw materials in parts by weight are: 8 parts of polypyrrole, 20 parts of lithium iron phosphate, 4 parts of polyaniline, 1 part of polyvinyl imidazole, 1 part of sodium vinyl sulfonate, N,N'- 1 part of bis(4-chlorophenyl)-N,N'-diphenyl-1,4-phenylenediamine.

[0017] A preparation method of a lithium battery cathode material, characterized in that the specific steps are:

[0018] (1) First, soak lithium iron phosphate in 0.2mol / L sodium hydroxide solution, soak for 2 hours, grind and mix with polypyrrole and polyaniline in a dust-free space, transfer to a high-temperature furnace after mixing, and heat at 600 Calcined at a constant temperature for 6 hours at ℃, and cooled to room temperature with the furnace at a speed of 2℃ to obtain a semi-finished product;

[0019] (2) Finally, mix the semi-finished product with polyvinyl imidazole, sodium vinylsulfonate, N,N'-bis(4-chlorophenyl)-N,N'-diphenyl-1,4-phenylenediamine And pl...

Embodiment 2

[0022] A lithium battery cathode material, the main raw materials in parts by weight are: 9 parts of polypyrrole, 24 parts of lithium iron phosphate, 5 parts of polyaniline, 1 part of polyvinyl imidazole, 1 part of sodium vinyl sulfonate, N,N'- 1 part of bis(4-chlorophenyl)-N,N'-diphenyl-1,4-phenylenediamine.

[0023] A preparation method of a lithium battery cathode material, characterized in that the specific steps are:

[0024] (1) First, soak lithium iron phosphate in 0.3mol / L sodium hydroxide solution, soak for 2 hours, grind and mix with polypyrrole and polyaniline in a dust-free space, and transfer to a high-temperature furnace after mixing. Calcined at a constant temperature for 6 hours at ℃, and cooled to room temperature with the furnace at a speed of 2℃ to obtain a semi-finished product;

[0025] (2) Finally, mix the semi-finished product with polyvinyl imidazole, sodium vinylsulfonate, N,N'-bis(4-chlorophenyl)-N,N'-diphenyl-1,4-phenylenediamine And placed in a ba...

Embodiment 3

[0028] A lithium battery cathode material, the main raw materials in parts by weight are: 10 parts of polypyrrole, 26 parts of lithium iron phosphate, 7 parts of polyaniline, 2 parts of polyvinyl imidazole, 2 parts of sodium vinyl sulfonate, N,N'- 2 parts of bis(4-chlorophenyl)-N,N'-diphenyl-1,4-phenylenediamine.

[0029] A preparation method of a lithium battery cathode material, characterized in that the specific steps are:

[0030] (1) First, soak lithium iron phosphate in 0.4mol / L sodium hydroxide solution, soak for 3 hours, grind and mix with polypyrrole and polyaniline in a dust-free space, transfer to a high-temperature furnace after mixing, and heat at 625 Calcined at a constant temperature for 7 hours at ℃, and cooled to room temperature with the furnace at a speed of 4℃ to obtain a semi-finished product;

[0031] (2) Finally, mix the semi-finished product with polyvinyl imidazole, sodium vinylsulfonate, N,N'-bis(4-chlorophenyl)-N,N'-diphenyl-1,4-phenylenediamine An...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Volumetric energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com