A kind of air cathode based on boron nitrogen carbon ternary covalent composite material and its preparation method and zinc-air secondary battery

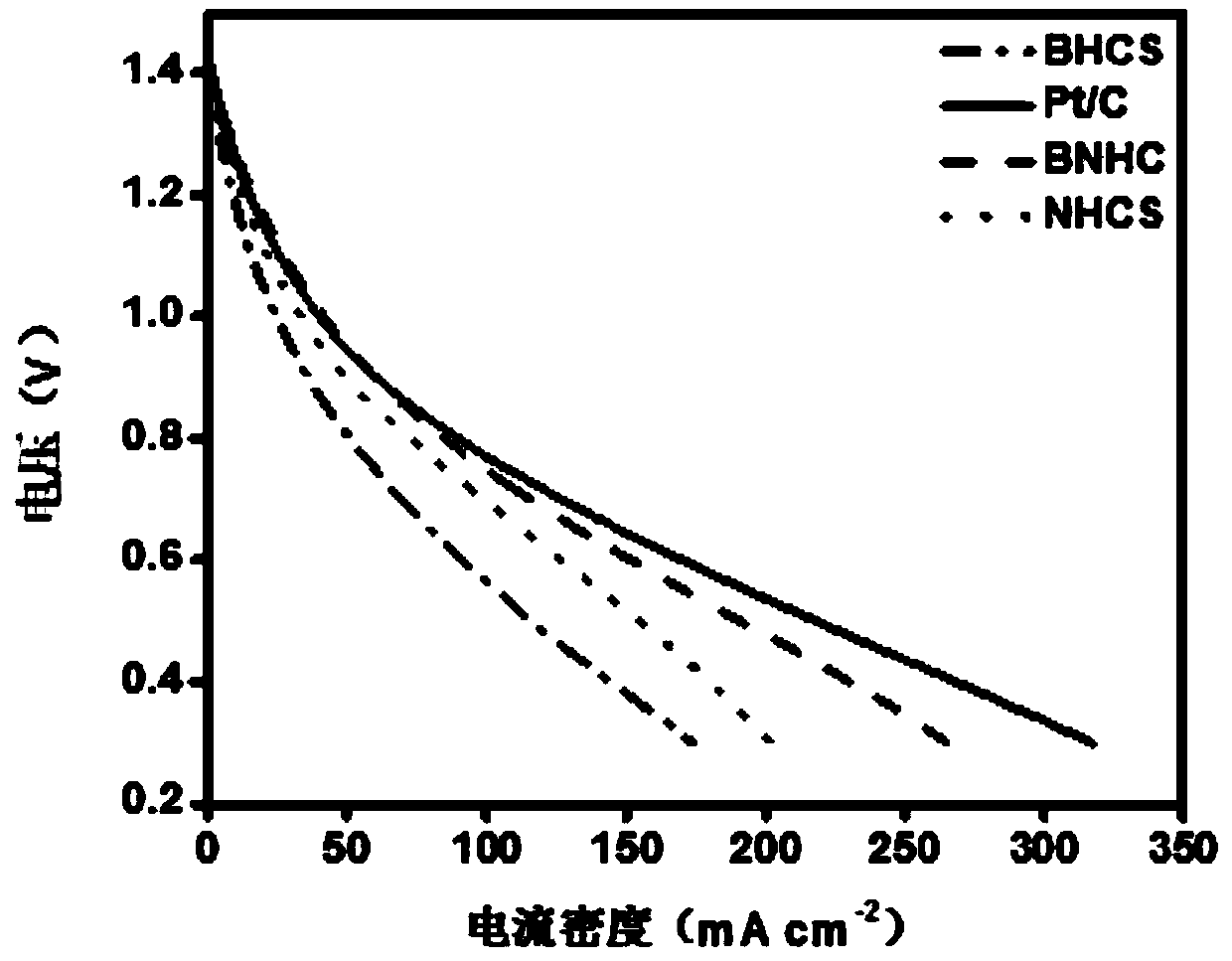

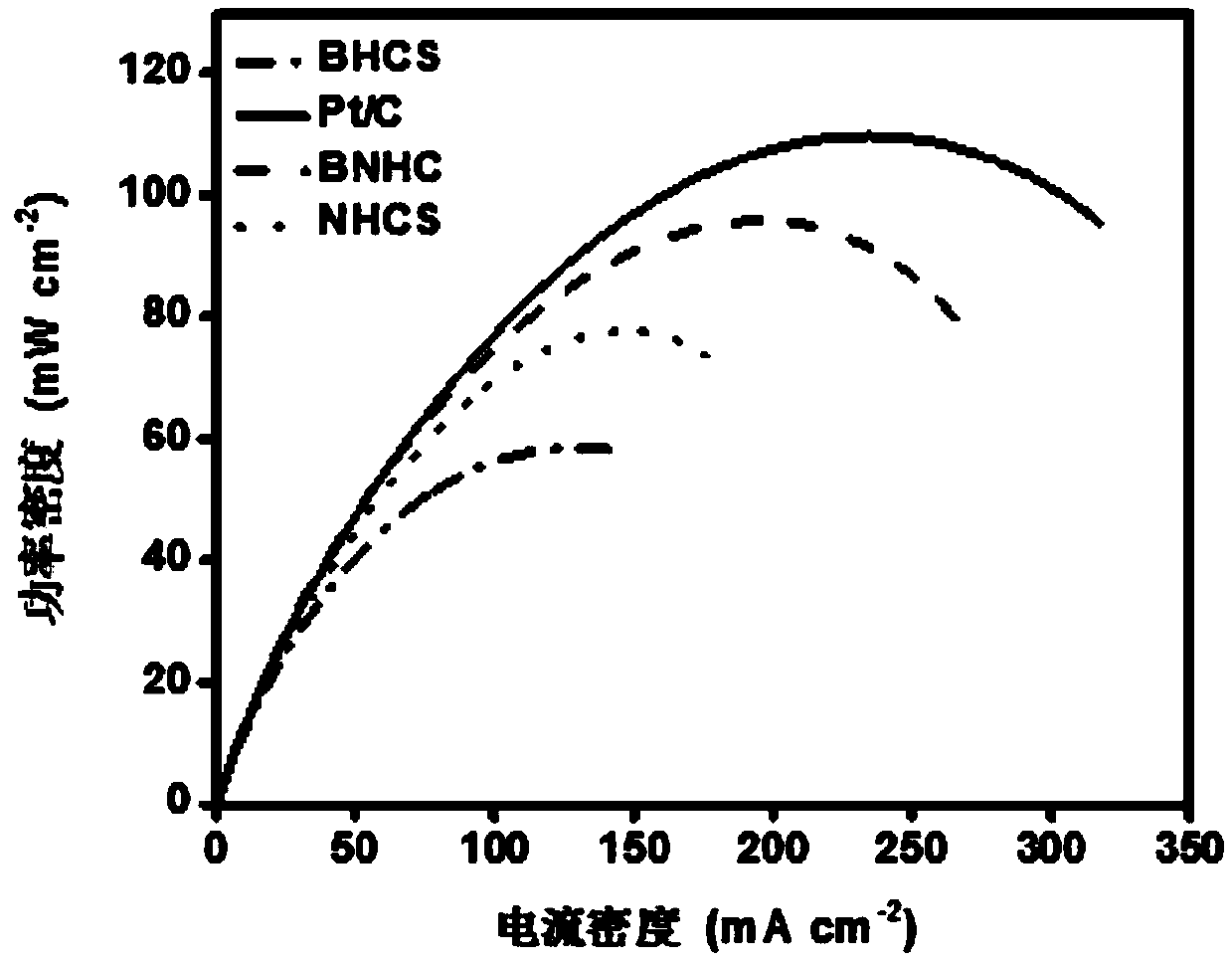

A boron-nitrogen-carbon ternary and composite material technology, which is applied in the direction of fuel cell half-cells and secondary battery-type half-cells, battery electrodes, circuits, etc., can solve low catalytic efficiency, unstable high-current discharge, battery Poor conductivity and other problems, to achieve the effect of improving catalytic performance, improving electrical conductivity, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Immerse 2cm*2cm carbon paper in 15wt% polytetrafluoroethylene emulsion for 5min, 10min, 15min, 20min, 25min, 30min, 40min to optimize the hydrophobic time.

Embodiment 2

[0041] Immerse 2cm*2cm carbon paper in 0wt%, 5wt%, 10wt%, 15wt% polytetrafluoroethylene emulsion for 10min to optimize the hydrophobic concentration.

Embodiment 3

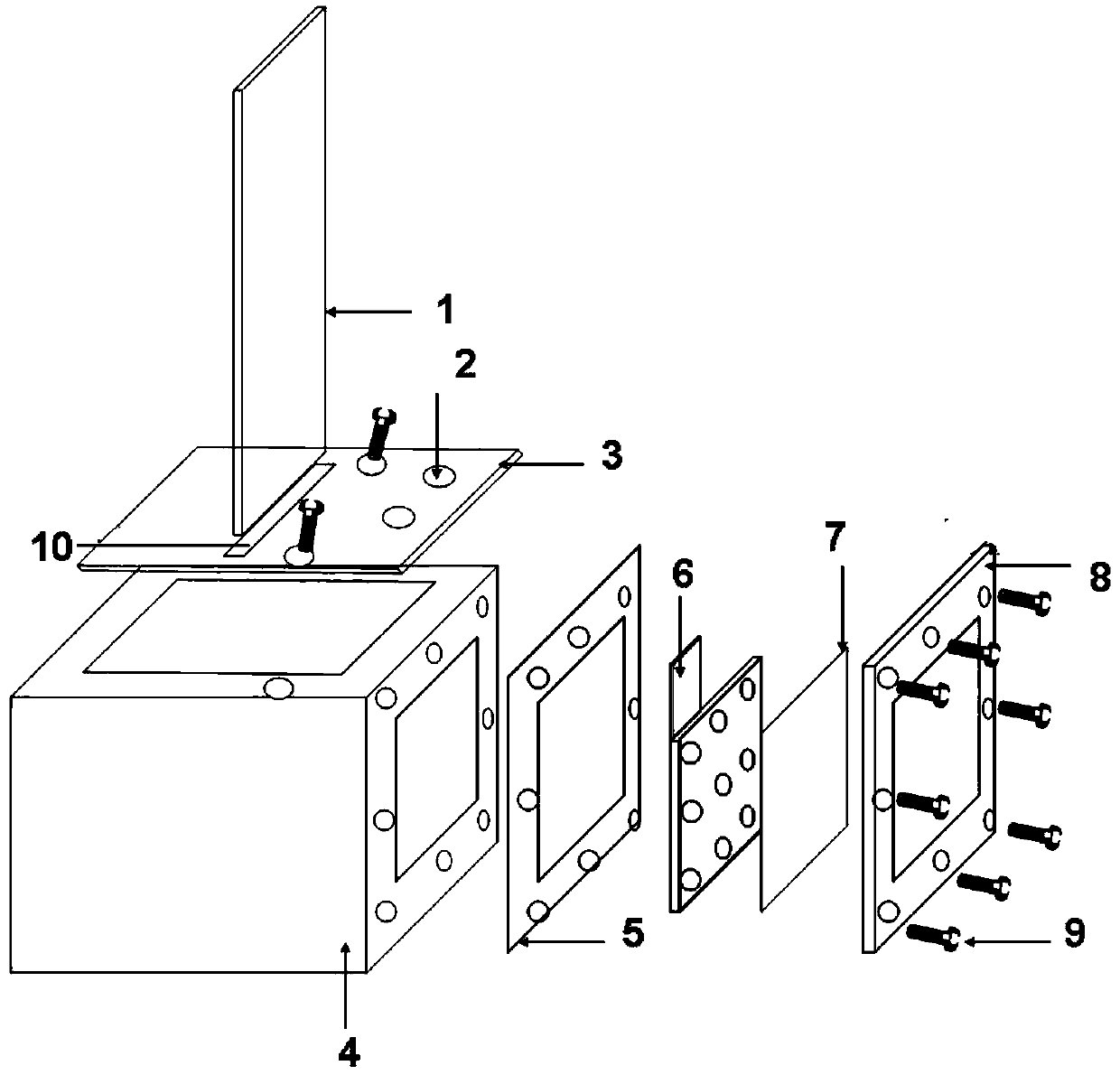

[0043] Soak the carbon paper in polytetrafluoroethylene emulsion (the mass concentration of polytetrafluoroethylene is 5wt%-60wt%, 10wt% is selected in this example) (the soaking time is 5-40min, 20min is selected in this example) , carry out hydrophobic treatment, dry at 80°C for 30min, and sinter at 360°C for 30min; acetylene black and polytetrafluoroethylene emulsion (the mass ratio of acetylene black to polytetrafluoroethylene emulsion is 7:3 to 2:8, In this example, 6:4 is selected; the mass concentration of polytetrafluoroethylene is 5wt%~60wt%, and 60wt% is selected in this example; the carbon load of acetylene black is 0.5~1.5mg / cm 2 , 1mg / cm was selected in this example 2 ) is dispersed and mixed in ethanol, and under a certain pressure, the above-mentioned mixed liquid is pressure-atomized on one side of the carbon paper that has been treated with water by pressure atomization, dried at 80°C for 30 minutes, and sintered at 360°C for 30 minutes;

[0044] Activated ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com