Accelerated test method for anti-PID performance of packaging adhesive film of photovoltaic assembly

A photovoltaic module packaging and testing method technology, applied in the monitoring of photovoltaic systems, photovoltaic power generation, photovoltaic modules, etc., can solve the high requirements for aging and testing equipment, accelerated testing methods for packaging film anti-PID performance, packaging film The characterization of the anti-PID performance is not convenient and fast enough to achieve the effect of saving test cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

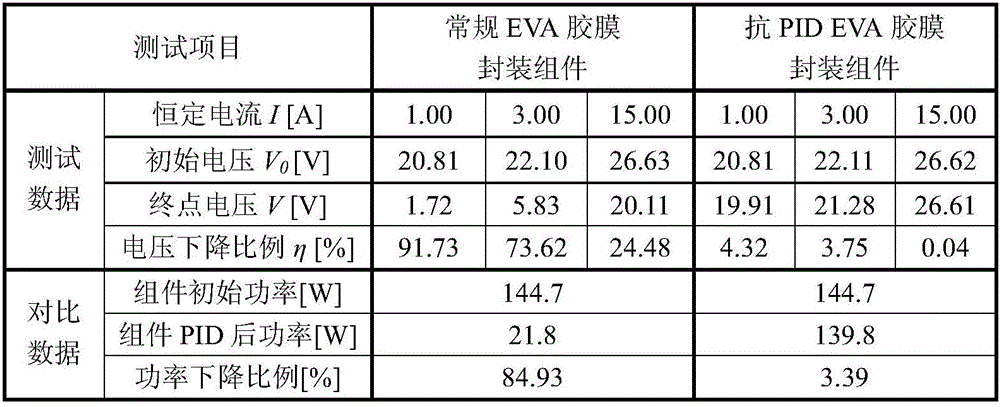

[0024] (1) Use conventional EVA film and anti-PID EVA film to encapsulate the same batch of P-type polysilicon cells with a refractive index of 2.08 respectively, and make two small photovoltaic modules containing 36 cells;

[0025] (2) After shading the front of each module, use a constant current source to connect the positive pole and negative pole of the module, pass a constant current of 1A, 3A and 15A in each module in turn, record the voltage value displayed by the constant current source under each current, as initial data V 0 ;

[0026] (3) Paste conductive aluminum foil on the glass surface of the module;

[0027] (4) Under the conditions of 85°C, 85%RH, and -2000V bias voltage, conduct a PID 48h test on the module;

[0028] (5) After shading the front of each component, use a constant current source to connect the positive and negative poles of the component, pass a constant current of 1A, 3A and 15A in each component in turn, and record the voltage value displaye...

Embodiment 2

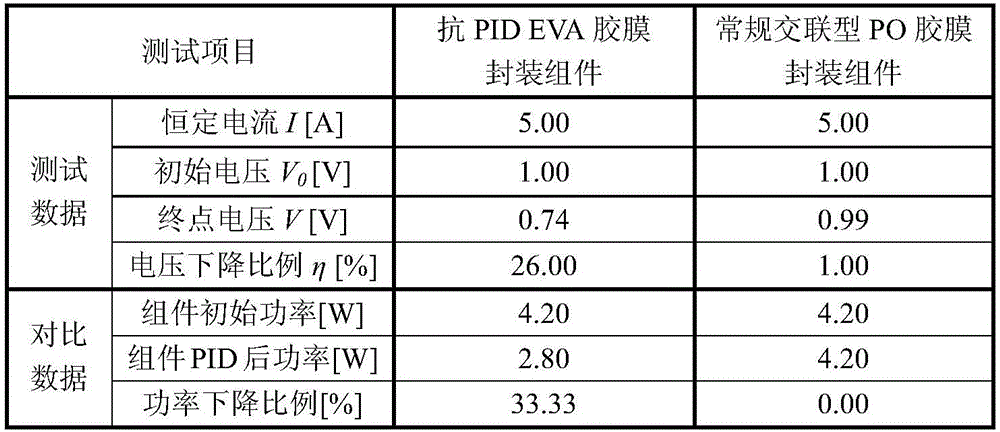

[0033] (1) Encapsulate the same batch of N-type monocrystalline cells of the same type with anti-PID EVA film and conventional cross-linked PO film respectively, and make two small photovoltaic modules containing one cell;

[0034] (2) After shading the front of each module, use a constant current source to connect the positive and negative electrodes of the module, pass a constant current of 5A in each module, record the voltage value displayed by the constant current source under each current, and use it as the initial data V 0 ;

[0035] (3) Paste conductive aluminum foil on the glass surface of the module;

[0036] (4) Under the conditions of 121°C, 100% RH, and +2000V bias voltage, conduct a PID 1h test on the module;

[0037] (5) After shading the front of each module, use a constant current source to connect the positive and negative electrodes of the module, pass a constant current of 5A in each module in turn, record the voltage value displayed by the constant curren...

Embodiment 3

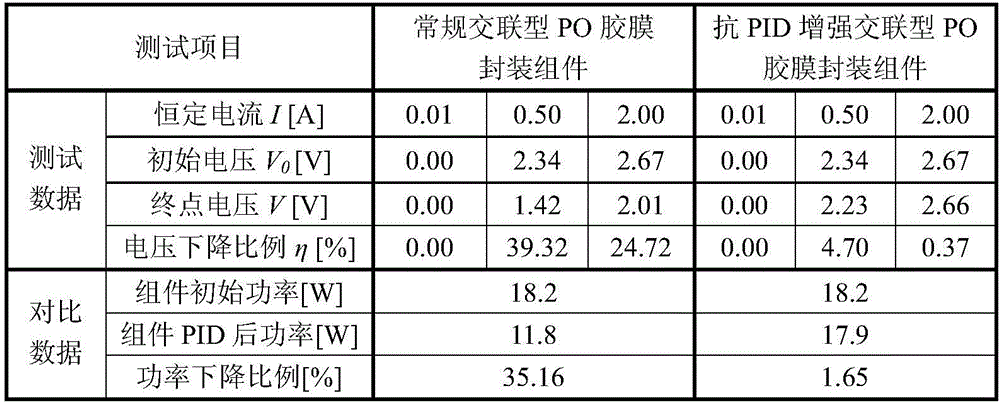

[0042] (1) Encapsulate the same batch of crystalline silicon heterojunction HIT cells with conventional cross-linked PO film and anti-PID enhanced cross-linked PO film to make two small photovoltaic modules containing 4 cells;

[0043] (2) After shading the front of each module, use a constant current source to connect the positive and negative electrodes of the module, pass a constant current of 0.01A, 0.5A and 2A in each module in turn, and record the voltage displayed by the constant current source under each current value, as the initial data V 0 ;

[0044] (3) Paste conductive aluminum foil on the glass surface of the module;

[0045] (4) Under the conditions of 60°C, 85% RH, and -600V bias voltage, conduct a PID 96h test on the module;

[0046] (5) After shading the front of each module, use a constant current source to connect the positive and negative electrodes of the module, pass a constant current of 0.01A, 0.5A and 2A in each module in turn, and record the voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com