Lithium ion secondary cell negative electrode material and method for manufacturing same

A secondary battery and negative electrode material technology, applied in the direction of secondary batteries, battery electrodes, negative electrodes, etc., can solve the problems of increased internal resistance, large expansion rate and shrinkage rate, and disconnection of electrical contacts, so as to achieve low-cost acquisition and increase Energy density, the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

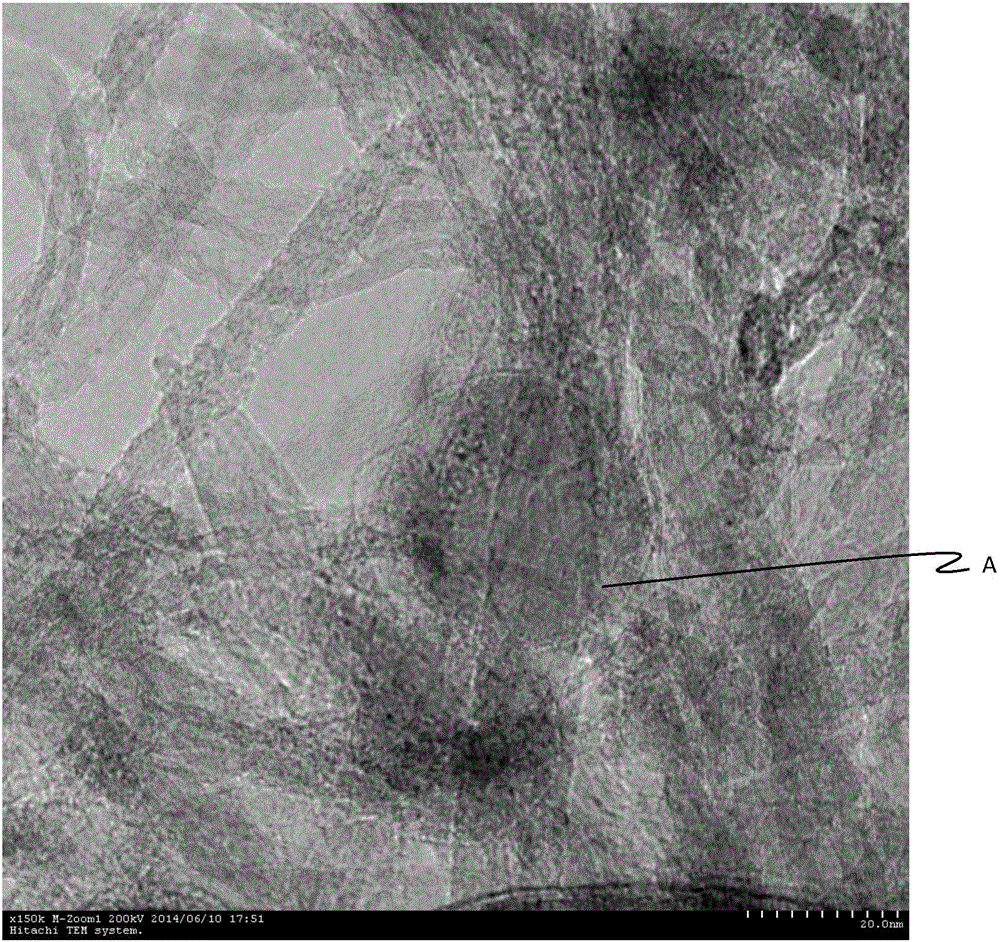

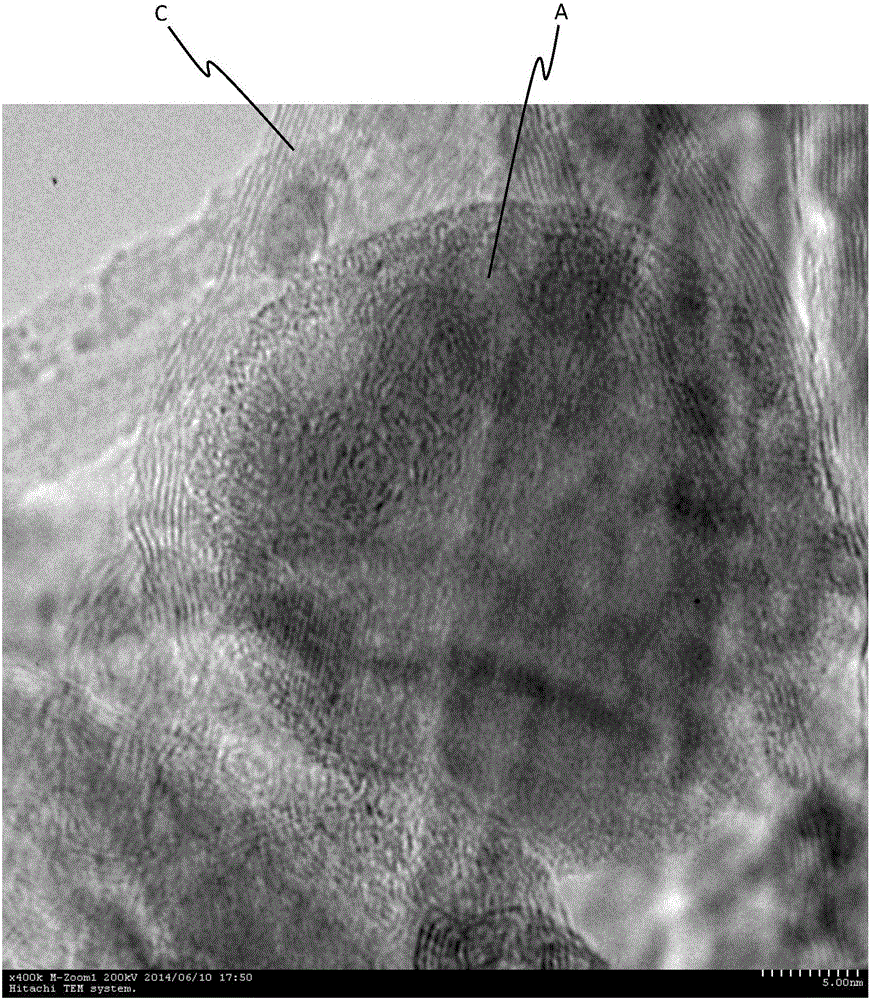

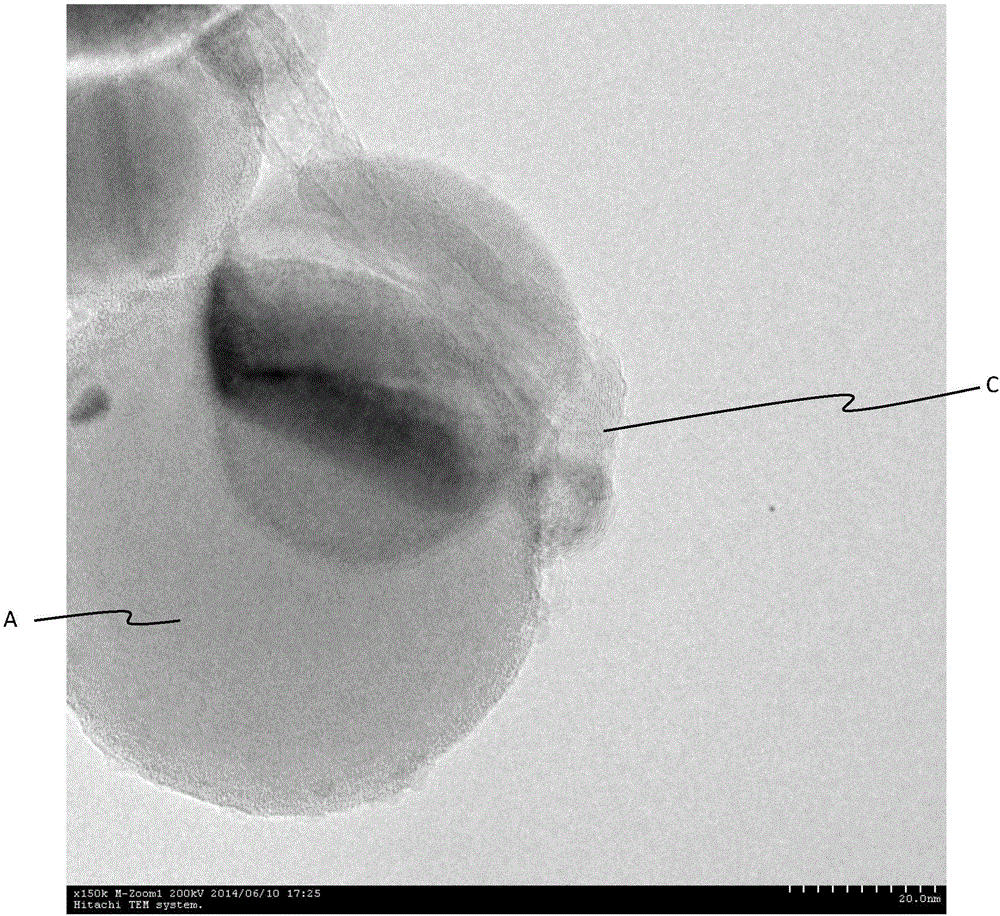

[0126] 3.1 g of Si particles [90% of the particle diameter in the volume-based cumulative particle size distribution is 200 nm or less] and carbon nanotubes (VGCF-XA (registered trademark): manufactured by Showa Denko Co., Ltd.; 95% or more of the fiber diameter of all fibers 2 nm to 40 nm and an aspect ratio of 10 to 15000) 1.3 g with a pulverizer (NOBILTA (trademark): manufactured by Hosokawa Micron Co., Ltd.. NOB-MINI) with an initial output power of 300 W (relative to the sample The unit volume is 4.3W / cm 3 ) was mechanochemically treated for 5 minutes to obtain a mechanochemically treated product (1) containing Si particles and carbon nanotubes. In this processed product, a three-dimensional entangled network structure formed of carbon nanotubes in which aggregates of carbon nanotubes were dispersed was formed, and Si particles were fused to the carbon nanotubes constituting the structure. Figure 1 ~ Figure 4A TEM image showing the fusion state of Si particles and carbo...

Embodiment 2

[0142] 5.0 g of Si particles [90% particle diameter in volume-based cumulative particle size distribution is 200 nm or less] and 0.6 g of carbon nanotubes (VGCF-XA (registered trademark): manufactured by Showa Denko Co., Ltd.) were used in a pulverizer (NOBILTA (trademark) : Hosokawa Micron Co., Ltd. product. NOB-MINI) was mechanochemically treated for 5 minutes to obtain a mechanochemically treated product (2) containing Si particles and carbon nanotubes. The processed product (2) has a three-dimensional entangled network structure formed of carbon nanotubes in which aggregates of carbon nanotubes are dispersed, and Si particles are fused to the carbon nanotubes constituting the structure.

[0143] 1.8 g of the treated product (2) and 13.5 g of graphite particles (SCMG (trademark): manufactured by Showa Denko Co., Ltd.) were crushed for 5 days with a pulverizer (NOBILTA (trademark): manufactured by Hosokawa Micron Co., Ltd.. NOB-MINI) minutes of mechanochemical treatment to o...

Embodiment 3

[0147] 3.1 g of Si particles [90% particle diameter in volume-based cumulative particle size distribution is 800 nm] and 1.3 g of carbon nanotubes (VGCF-XA (registered trademark): manufactured by Showa Denko Co., Ltd.) were used in a pulverizer (NOBILTA (trademark): Hosokawa Micron Co., Ltd. Manufactured. NOB-MINI) with an initial output power of 300W (4.3W / cm with respect to the unit volume of the sample 3 ) was mechanochemically treated for 5 minutes to obtain a mechanochemically treated product (3) containing Si particles and carbon nanotubes. The processed product (3) has a three-dimensional entangled network structure formed of carbon nanotubes in which aggregates of carbon nanotubes are dispersed, and Si particles are fused to the carbon nanotubes constituting the structure.

[0148] Next, 1.3 g of the aforementioned mechanochemically treated product (3) and 7.8 g of graphite particles (SCMG (trademark): manufactured by Showa Denko Co., Ltd.) were crushed with a pulveriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| face spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com