Solid feed and preparation method thereof

A feed and solid state technology, applied in the field of solid feed and the preparation of the solid feed, can solve the problems of liquid propylene glycol needing to be administered, high production cost, unfavorable milk production of dairy cows, etc. The effect of manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

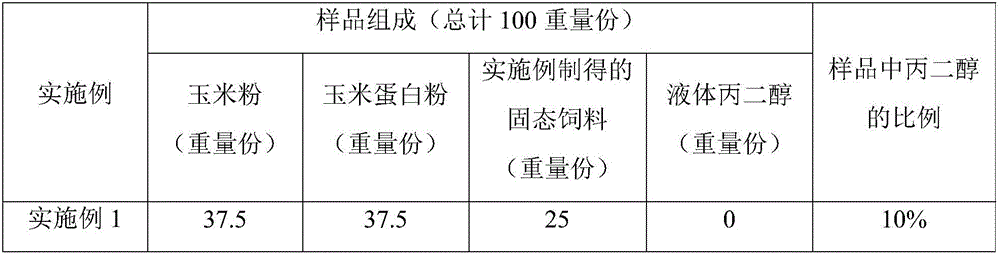

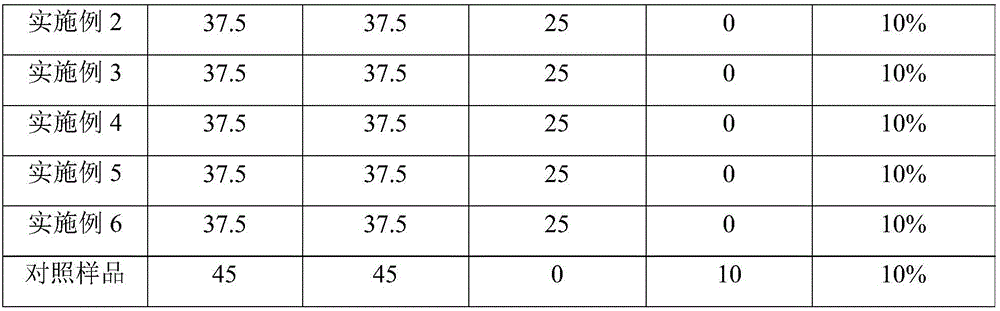

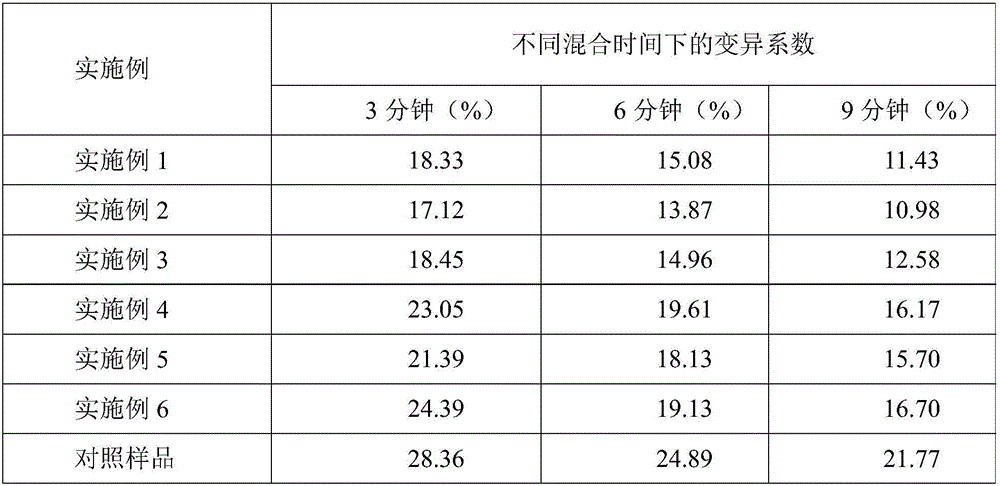

Examples

preparation example Construction

[0034] In a second aspect, the present invention also provides a method for preparing a solid feed, the method comprising:

[0035] (1) Spray propylene glycol onto the feed carrier raw material, and then make the propylene glycol mix with the feed carrier raw material by stirring;

[0036] (2) The resulting mixture is sealed and stored at room temperature for 6-48 hours;

[0037] Wherein, the consumption of feed carrier material and propylene glycol makes, take the total weight of solid feed as a basis, the content of feed carrier in terms of dry weight is 20-65% by weight, the content of propylene glycol is 21-75% by weight, and the content of water is 3-14% by weight.

[0038]Preferably, the amount of the feed carrier raw material and propylene glycol is such that, based on the total weight of the solid feed, the content of the feed carrier in terms of dry weight is 40-60% by weight, the content of propylene glycol is 33-55% by weight, and the content of water It is 8-14% ...

Embodiment 1

[0053] This embodiment is used to illustrate the solid feed of the present invention and its preparation method.

[0054] 100kg sugar beet granular meal (purchased from COFCO Tunhe Co., Ltd.) was pulverized, and mixed with corn starch, corn stalk powder, stone powder, and soybean meal powder in a certain proportion to obtain a feed carrier with a moisture content of 12% by weight and a particle size of 200 mesh ( The weight ratio of sugar beet meal powder, corn starch, corn straw powder, stone powder and soybean meal powder is 10:0.5:2:0.5:0.5); under the operating pressure of 1.5MPa, 67kg of propylene glycol is evenly sprayed into the feed carrier by using a high-pressure water gun, Use a horizontal shaft mixer to stir the mixture of the two at room temperature, the stirring speed is 28rpm, and the time is 5min, so that the propylene glycol and the feed carrier are evenly mixed, and the mixture of the evenly mixed propylene glycol and the feed carrier is sealed and preserved. ...

Embodiment 2

[0056] This embodiment is used to illustrate the solid feed of the present invention and its preparation method.

[0057] 150kg beet granule meal (purchased from COFCO Tunhe Co., Ltd.) was pulverized, and mixed with corn starch, corn stalk powder, stone powder, and soybean meal powder in a certain proportion to obtain a feed carrier with a moisture content of 11% by weight and a particle size of 80 meshes ( The weight ratio of beet meal powder, corn starch, corn straw powder, stone powder and soybean meal powder is 10:0.5:1:0.5:0.5; 100kg of propylene glycol is evenly sprayed into the feed carrier with a high-pressure water gun under the operating pressure of 1MPa. The shaft type mixer stirs the mixture of the two at room temperature, the stirring speed is 30rpm, and the time is 10min, so that the propylene glycol and the feed carrier are evenly mixed, and the mixture of the evenly mixed propylene glycol and the feed carrier is sealed and stored. 12 hours, so that the propylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com