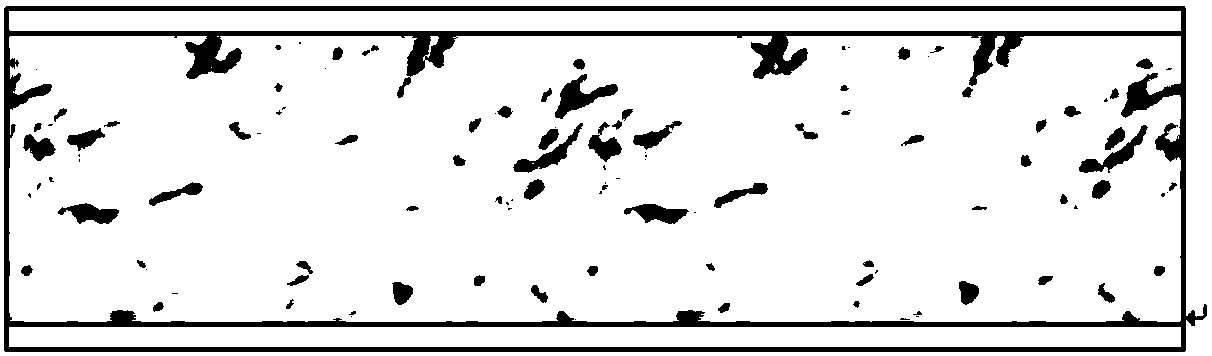

An inner surface wrinkled cigarette paper

A cigarette paper and inner surface technology, which is applied in the field of tobacco, can solve problems such as insufficient burning of cigarette shreds, shredded cigarettes and empty ends, and decline in smoking quality, so as to reduce shredded shreds and empty ends, improve the combustion state, and improve the quality of smoking. The effect of combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

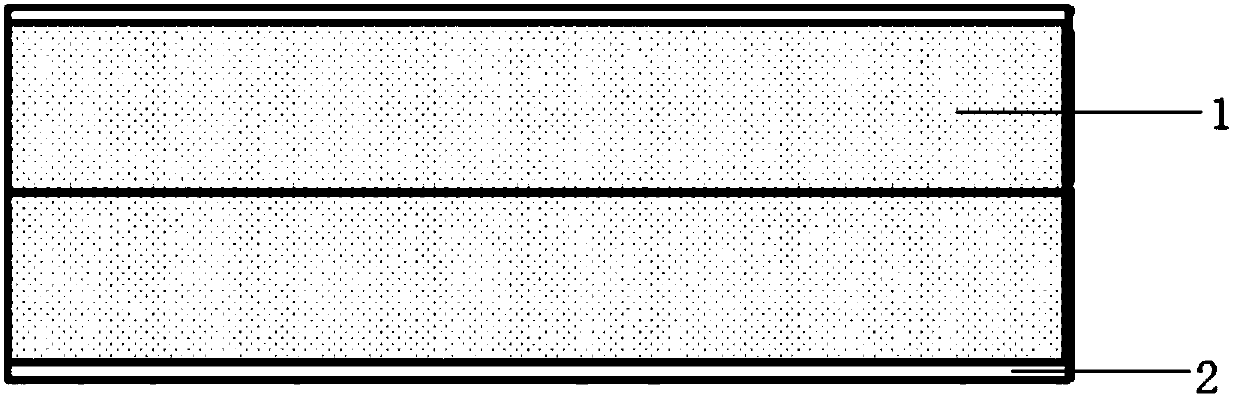

[0045] 1. Pulping and papermaking: Papermaking is carried out according to the normal cigarette paper process. The long fiber of coniferous wood: the long fiber of hardwood: the mass ratio of short fiber is 4:3:2 and is put into the beating machine for beating, and a small amount of calcium carbonate is added in addition, and calcium carbonate accounts for about 20% of the fiber mass; and the prepared cigarette 50 kg of special reinforcing agent for paper (accounting for 5 wt% of the cigarette paper) is added in the sizing section of the paper machine, and coated on the inner surface of the cigarette paper substrate to obtain functional cigarette paper.

[0046] 2. Inner surface wrinkling: mark the inner surface of the functional cigarette paper obtained above with a wrinkled area, and use a wrinkling scraper on the surface of the cylindrical drying cylinder to wrinkle the inner surface of the functional cigarette paper within the marked wrinkled area. wrinkling; the wrinkling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com