Fibroin bone nail and preparation method thereof

A technology of silk protein and bone nails, which is applied in the field of silk protein bone nails and its preparation, can solve the problems of insufficient bone nail strength and low compatibility with human tissue, and achieve good human affinity, good environment and human adaptability, The effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

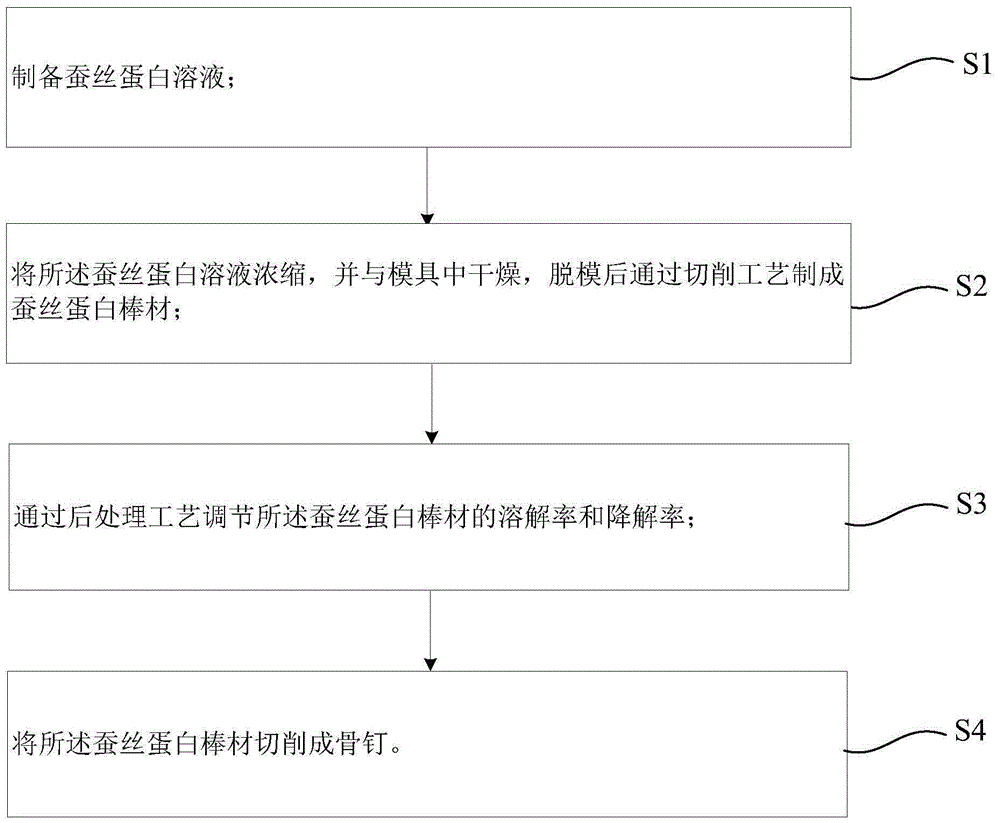

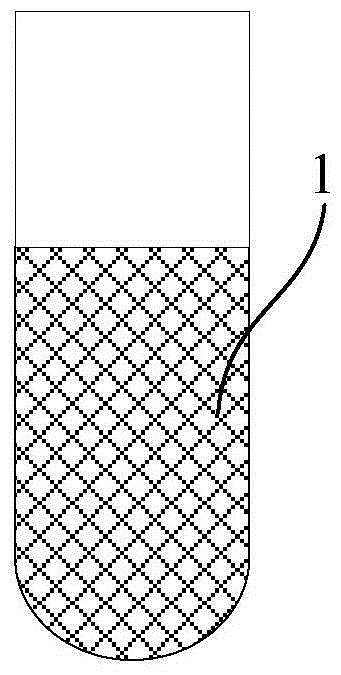

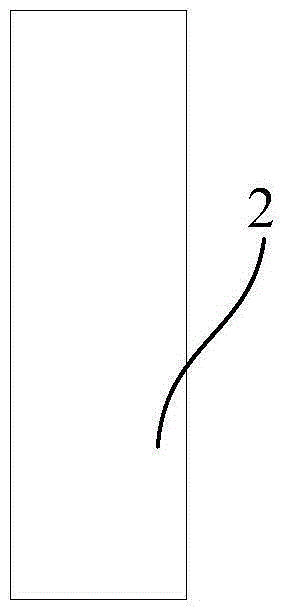

[0041] Such as figure 1 As shown, the present invention provides a kind of preparation method of silk protein bone nail, and concrete preparation steps are:

[0042] First, step S1 is performed to prepare a silk protein solution.

[0043] The specific method for preparing the silk protein microneedle is:

[0044] 1) Heat the cocoons in sodium carbonate solution to degumming and form silk.

[0045] As an example, the concentration of the sodium carbonate solution is 0-100 g / L, and the mass ratio of the added cocoon to the sodium carbonate solution is 10:(1-100) g / L. The heating method is electric furnace heating or pressure cooker heating, the heating temperature is 50-120°C, and the heating time is 1s-1000h. By adjusting the process parameters of the degumming process, the molecular weight of silk protein can be controlled.

[0046] 2) Washing the silk in ultrapure water, repeating several times, and drying.

[0047] As an example, the washing in this step may be stirring w...

Embodiment 2

[0065] What this embodiment prepares is silk protein bone nail.

[0066] Such as Figure 2 ~ Figure 4 As shown, 1 is the silk protein solution, 2 is the silk protein rod, and 3 is the silk protein bone nail. The specific implementation steps include:

[0067] First execute step S1: figure 2 As indicated, silk protein solution 1 was prepared.

[0068] Specifically, in this embodiment, first, each portion of 10g silkworm cocoon is cut into pieces and placed in 4L of sodium carbonate solution with a concentration of 2g / L, heated to boil in an electric furnace and magnetically stirred at a speed of 200r / min, and the heating time is 0.5h .

[0069] Then, each portion of boiled silk is placed in 2L of ultrapure water, stirred, washed and kneaded dry, repeated 6 times, and then dried, the stirring speed is 200r / min, and the stirring time is 20min. The volume of ultrapure water changed each time is 2L, the drying method is 25°C and normal pressure (0.1MPa).

[0070] Next, immer...

Embodiment 3

[0079] What this embodiment prepares is silk protein bone nail.

[0080] Such as Figure 5 ~ Figure 8 As shown, 4 is vitamin D, 5 is the silk protein solution, 6 is the mixed solution of vitamin D and silk protein, 7 is the silk protein rod containing vitamin D, and 8 is the silk protein bone nail containing vitamin D. The specific implementation steps include:

[0081] First execute step S1: Figure 5 As shown, prepare silk protein solution 5.

[0082] Specifically, in this embodiment, first, each portion of 10g silkworm cocoon is cut into pieces and placed in 4L of sodium carbonate solution with a concentration of 2g / L, heated to boil in an electric furnace and magnetically stirred at a speed of 200r / min, and the heating time is 0.5h .

[0083] Then, each portion of boiled silk is placed in 2L of ultrapure water, stirred, washed and kneaded dry, repeated 6 times, and then dried, the stirring speed is 200r / min, and the stirring time is 20min. The volume of ultrapure water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com