A kind of purification treatment technology of high concentration NOx process tail gas

A technology for purification treatment and process tail gas, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of high NOx concentration, low treatment temperature, and easy fluctuation of content, so as to improve removal rate and low operating cost , reduce the effect of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

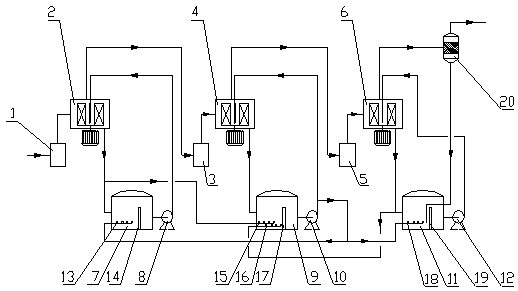

[0041] Use as figure 1 The purification treatment process shown, the gas volume Q=7000Nm 3 / h, NOx concentration is 10000mg / m 3 , Where the NO concentration is 7000mg / m 3 The process exhaust gas is processed. In the embodiment of the present invention, the first-stage reactor, the second-stage reactor and the third-stage reactor all adopt a rotating bed reactor.

[0042] The process tail gas first enters the primary oxidizer, which uses O 2 Is the oxidant, O 2 The filling volume is 30m 3 / h, the oxidation time is 20 seconds; the exhaust gas from the oxidation treatment enters the first-stage reactor, and NOx is absorbed and treated by the urea solution with a mass concentration of 23% in the reactor. The treatment conditions are: temperature 15℃, liquid-gas ratio 20 L / m 3 , The rotating bed speed is 1500 rpm; the volume flow of the absorption liquid out of the primary reactor into the secondary storage tank is 1 / 4 of the total flow of the absorption liquid out of the reactor; the ...

Embodiment 2

[0045] Counter air volume Q=5000Nm 3 / h, NOx concentration is 18000mg / m 3 , Where the NO concentration is 12000mg / m 3 The process exhaust gas is processed. In the embodiment of the present invention, the first-stage reactor and the third-stage reactor adopt a rotating bed reactor, and the second-stage reactor adopts a packed absorption tower.

[0046] The process tail gas first enters the primary oxidizer, which uses O 3 Is the oxidant, O 3 The filling volume is 17m 3 / h, the oxidation time is 10 seconds; the exhaust gas from the oxidation treatment enters the first-stage reactor, and the NOx is absorbed and treated by the urea solution with a mass concentration of 25% in the reactor. The treatment conditions are: temperature 10℃, liquid-gas ratio 25 L / m 3 , The rotating bed speed is 2000 rpm; the volume flow rate of the absorption liquid from the primary reactor into the secondary storage tank is 1 / 3 of the total flow of the absorption liquid from the reactor; the tail gas from th...

Embodiment 3

[0049] Counter air volume Q=4000Nm 3 / h, NOx concentration is 7000mg / m 3 , Where the NO concentration is 5000mg / m 3 The process exhaust gas is processed. In the embodiment of the present invention, the first-stage reactor and the third-stage reactor adopt a rotating bed reactor, and the second-stage reactor adopts a packed absorption tower.

[0050] The process tail gas first enters the primary oxidizer, which uses O 2 Is the oxidant, O 2 The filling volume is 10m 3 / h, the oxidation time is 15 seconds; the exhaust gas from the oxidation treatment enters the first-stage reactor, and the NOx is absorbed and treated by the urea solution with a mass concentration of 15% in the reactor 2. The treatment conditions are: temperature 10℃, liquid-gas ratio 15 L / m 3 , The rotating bed speed is 1000 rpm; the volume flow of the absorption liquid from the first reactor into the second storage tank is 1 / 4 of the total flow of the absorption liquid from the reactor; the tail gas from the first re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com