Extruding-expanding molding method for rim provided with flange

A flange flange and rim technology, which is applied in the field of rim forming and extrusion molding of rims with flange flanges, can solve the problems of large investment in forming mold tooling and equipment, low material utilization rate, and low forming efficiency. Achieve the effects of shortening machining hours, improving material utilization, and improving forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Cutting

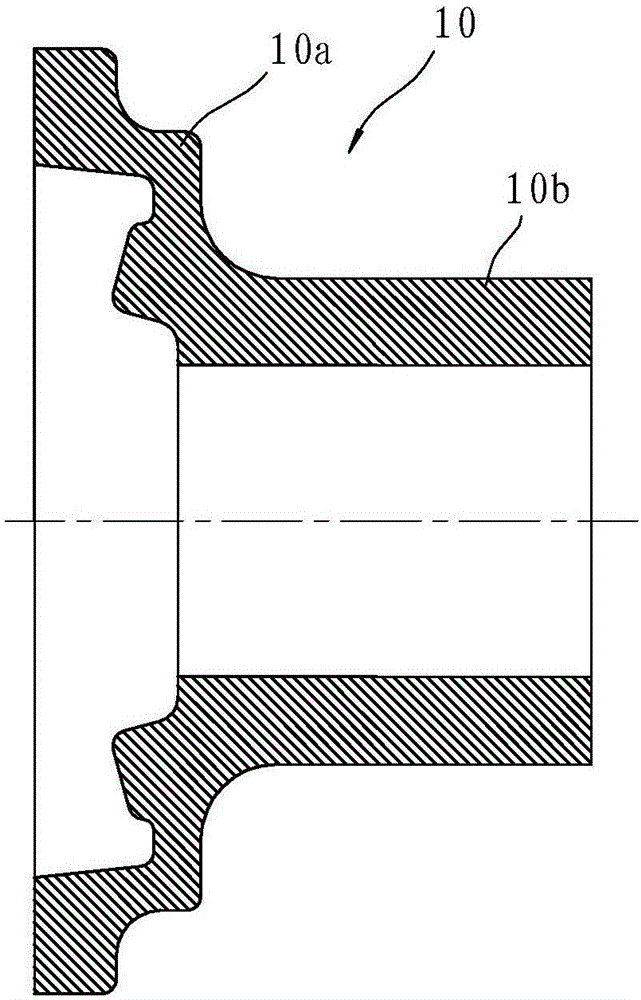

[0031] 7075 aluminum alloy extruded rods with a diameter of 195mm, the length of which is 327mm behind the two circular end faces of the billet placed by the car.

[0032] (2) Heating

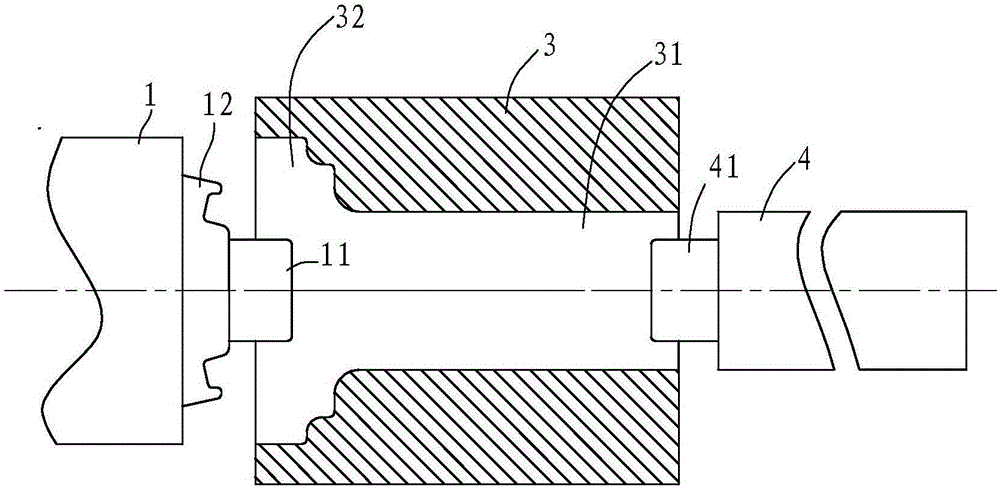

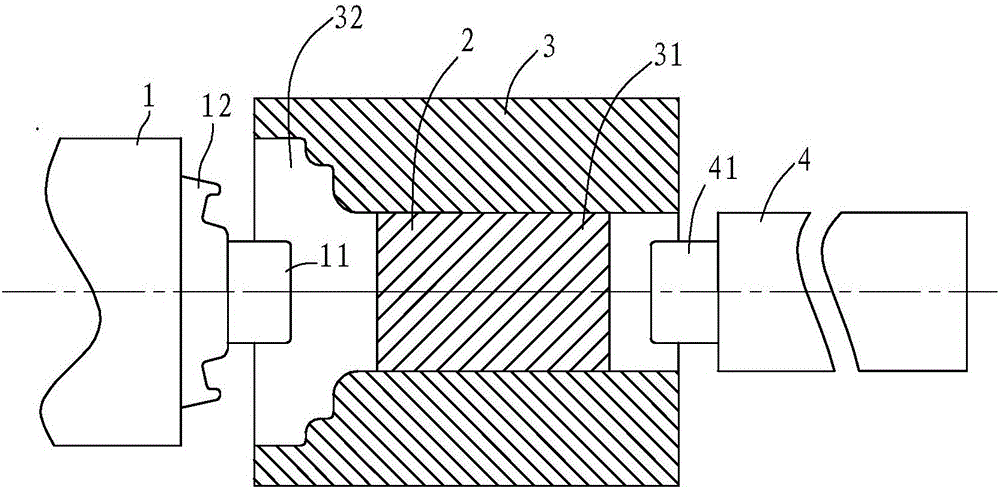

[0033] The aluminum alloy billet is heated to 370°C ± 5°C, and held for 2 hours after reaching temperature; the extrusion die is heated to 350°C ± 5°C, and held for 5 hours after reaching temperature. Such as figure 2 As shown, the extrusion die includes a die 3, a flange punch 1 and a shaft tube punch 4, the die 3 is axially hollow to form a cavity 31 and one end forms a flare 32 adapted to the flange of the rim; The flange punch 1 corresponds to the setting of the die 3. The flange punch 1 includes a first convex head 11 for forming the hollow cavity of the rim and a forming portion 12 that cooperates with the flare 32 to form the flange of the rim. The convex head 11 protrudes from the middle part of the molding part 12, and the other end of the half-axis tube punch ...

Embodiment 2

[0040] (1) Cutting

[0041] AZ80 magnesium alloy extruded bar with a diameter of 195mm, after the two circular end faces of the billet placed by Cheping, the length is 329mm.

[0042] (2) Heating

[0043] The heating temperature of the magnesium alloy billet is 335°C±5°C, and it is kept for 2 hours after reaching the temperature; the extrusion die is heated to 300°C±5°C, and it is kept for 5 hours after reaching the temperature. Refer to Example 1 for the structure of the extrusion die.

[0044] (3) Two-way extrusion and expansion forming

[0045] The billet 2 after the heating process is assembled in the die 3; the flange punch 1 and the half-axis tube punch 4 are extruded in the same direction synchronously, the bidirectional feed extrusion speed is 1.5mm / s, and the bidirectional synchronous displacement difference cooperative control is set. Set 0.2mm. After contacting the blank, the flange punch 1 stops running after the extrusion metal deformation feed rate is 75mm, a...

Embodiment 3

[0050] (1) Cutting

[0051] AZ91 magnesium alloy extruded bar with a diameter of 195mm, after the two round end faces of the billet placed by Cheping, the length is 330mm.

[0052] (2) Heating

[0053] The heating temperature of the magnesium alloy billet is 300°C±5°C, and it is kept for 4 hours after reaching the temperature; the mold is heated to 300°C±5°C, and it is kept for 5 hours after reaching the temperature.

[0054] (3) Two-way extrusion and expansion forming

[0055] The billet 2 after the heating process is assembled in the die 3; the flange punch 1 and the half-axis tube punch 4 are extruded in the same direction and synchronously, the bidirectional feed extrusion speed is 1mm / s, and the bidirectional synchronous displacement difference is set by cooperative control 0.2mm. After contacting the blank, the flange punch 1 stops running after the extrusion metal deformation feed rate is 80mm, and the half-axis tube punch 4 continues to run (speed 1.5mm / s) to the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com