A multi-layer heavy metal filter device

A filtering device and heavy metal technology, which is applied in the direction of filtration separation, filtration treatment, filtration circuit, etc., can solve the problems of restricting sewage treatment efficiency and slow coagulation, and achieve good filtration effect, long service life and low heavy metal content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

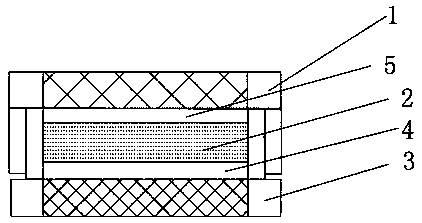

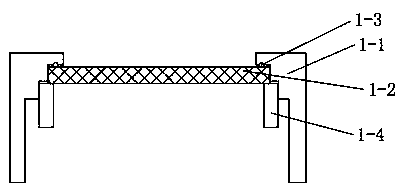

[0036] Such as Figure 1-4 As shown, the multi-layer heavy metal filtering device includes a primary filter grid 1, a secondary filter grid 3, an inorganic polymer filter plate 2 between the primary filter grid 1 and the secondary filter grid 3 . The polymer flocculation microporous plate 4 located at the lower end of the inorganic polymeric filter plate 2, the primary filter grid 1 and the secondary filter grid 3 are connected by thread grooves, and the polymer flocculation micropore 4 Located between the inorganic polymeric filter plate 2 and the secondary filter grid 3, the primary filter grid 1 includes a lower frame 1-1 with a stepped structure, a primary filter 1-2 made of stainless steel, Ring-shaped ring structure 1-4, the first-stage filter screen 1-2 is placed on the lower frame 1-1, and is screw-fixed by the ring 1-4, and the second-stage filter grid 3 includes The upper frame 3-1, the secondary filter screen 3-2 located in the center of the upper frame 3-1, the co...

Embodiment 2

[0045] Carry out simulation experiments with the multi-layer heavy metal filter device in embodiment 1 as filter device, dispose Zn respectively 2+ 、Cu 2 + , Pb 2+ 、Cd 2+ , Hg 2+ and Ni 2+ simulated heavy metal waste liquid. Flocculation test conditions: Take 500mL simulated heavy metal water samples respectively, adjust the pH value to 7-9, carry out flocculation filtration through the filter device, take the filtrate and measure the residual heavy metal ion concentration on the A-Analyst 300 atomic absorption spectrophotometer, and the treatment effect As described in Table 1:

[0046] Table 1 The polymer heavy metal flocculant of the present invention is to the removal effect of free heavy metal ions

[0047]

[0048] The simulated reaction to various heavy metal wastewater shows that the polymer heavy metal flocculant of the present invention has a good flocculation effect, has a good trapping effect on heavy metal ions, and has a treatment efficiency of o...

Embodiment 3

[0050] Carry out the simulation experiment with the multi-layer heavy metal filtering device in embodiment 1 as the filtering device, take commercially available ACPF, DTCR and TMT-18 as comparative examples, configure copper concentration as 120mg / L, COD is about 1000mg / L blue Color mixing simulates heavy metal waste liquid. Flocculation test conditions: take 500mL simulated heavy metal water samples, adjust the pH value to 7-9, add the medicament, use the time-variable speed six-way mixer to stir at 200-240r / min for 5min, and stir at 100-120r / min for 10min, Slowly stir again at 50-60r / min for 10min, let stand for 35min, filter the supernatant after sedimentation, take the filtrate and measure the residual heavy metal ion concentration on the A-Analyst 300 atomic absorption spectrophotometer; adjust the pH value to 7 -9, carry out flocculation filtration by filter device, get filtrate and measure residual heavy metal ion concentration on A-Analyst 300 type atomic absorption s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| micropore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com