Rapid start method for integrated autotrophic denitrification system

An autotrophic denitrification, quick start technology, applied in chemical instruments and methods, water treatment parameter control, sustainable biological treatment, etc., can solve the problems of unstable operation, long start-up time, low total nitrogen removal load, etc. Short start-up time, stable operation, and the effect of inhibiting proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

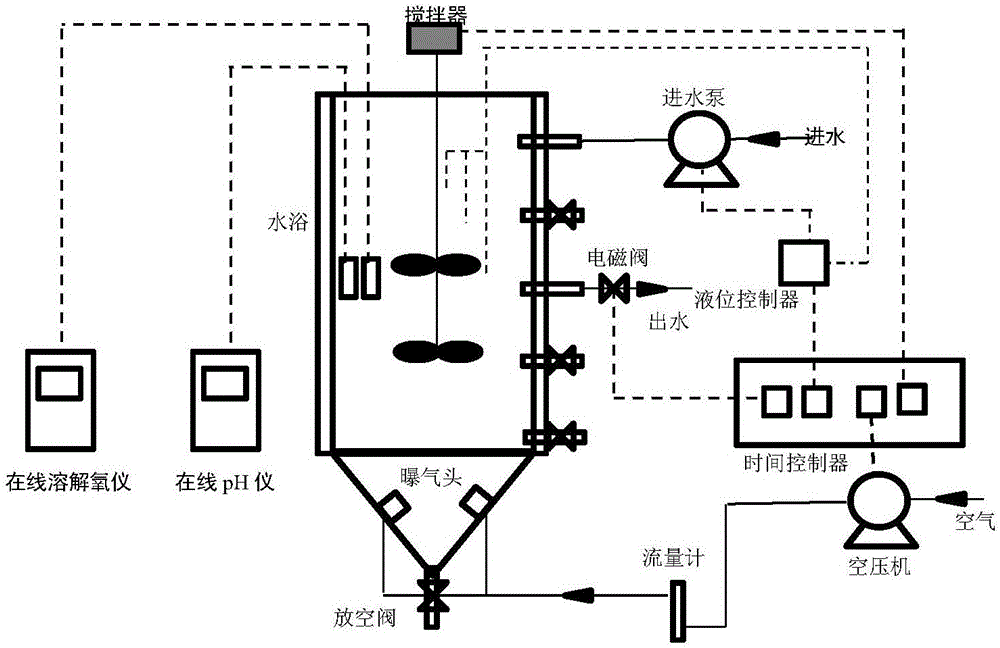

[0025] The first step, the establishment of an integrated autotrophic denitrification system

[0026] 1. Inoculate 3.5L of short-range nitrification sludge and 3L of anammox sludge cultivated in this laboratory into an SBR reactor with a total volume of 8L and an effective volume of 7L (see figure 1 ), the sludge concentration in the reactor after inoculation was 3480mgSS / L.

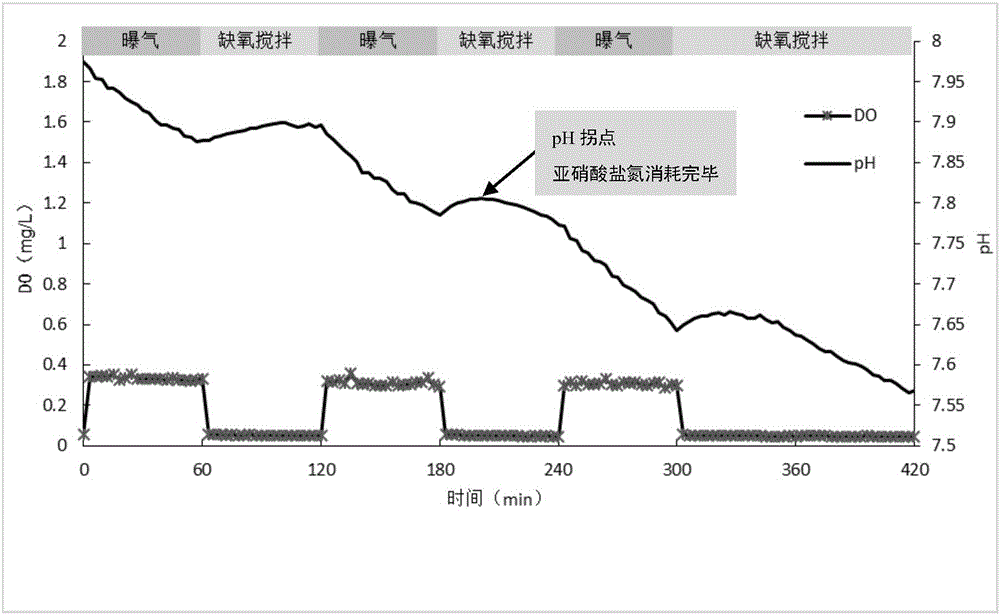

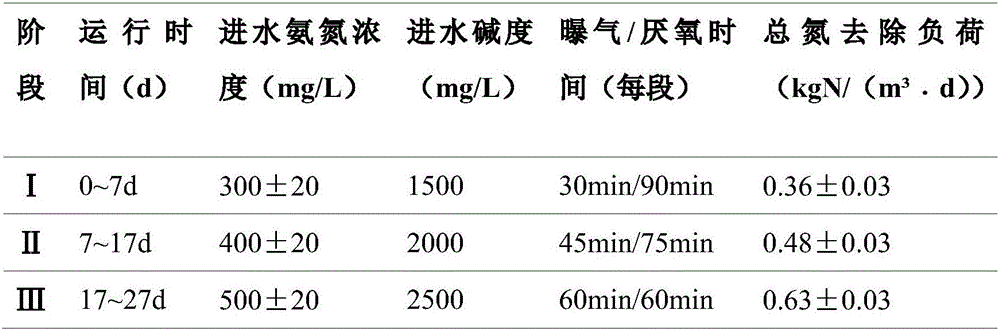

[0027] 2. According to the measured nitrite nitrogen accumulation rate and consumption rate, determine the operation mode of the SBR reactor, each cycle is: water intake 20min, reaction 360min (3 aeration / anoxic sections, each aeration time 30min, anoxic time 90min), stirring and degassing for 60min, sedimentation for 30min, effluent for 5min, idle for 5min; 3 cycles per day, each cycle is 8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com