A printing and dyeing wastewater pretreatment method and device

A pretreatment device, a technology for printing and dyeing wastewater, applied in the textile industry wastewater treatment, multi-stage water treatment, water/sewage treatment and other directions, can solve the problems of effluent treatment, large sludge output, etc. The device and method have the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

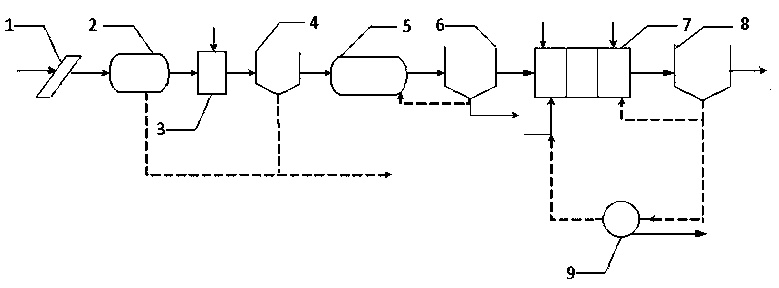

[0061] Embodiment 1, when actually put into use:

[0062] 1) The wastewater discharged by the enterprise first passes through the grid 1 to remove large particles;

[0063] 2) The grid 1 then enters the regulating tank 2 to make the water quality uniform and even;

[0064] 3) The effluent from the adjustment tank 2 passes through the coagulation tank 3, and 25% FeSO is added 4 and 30% liquid caustic soda, dosage is respectively 500ppm and 300ppm, carries out mud-water separation through primary settling tank 4 again;

[0065] 4) The effluent of the primary sedimentation tank 4 is biochemically treated through the oxidation ditch 5. The residence time of this process section is 45h, and the refractory organic matter is further degraded, and then separated from the mud and water by the secondary sedimentation tank 6;

[0066] 5) The effluent from the secondary settling tank 6 enters the magnetic coagulation tank 7, and polyferron, 1% PAM and magnetic powder, namely Fe, are add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com