Ceramic permeable brick and preparation method thereof

A technology of permeable bricks and ceramics, which is applied in the direction of ceramic products, ceramic material production, clay products, etc., can solve problems such as poor wear resistance, aggravated environmental pollution, and blockage of permeable bricks, and achieves simple and feasible preparation methods, reducing Effects of environmental pollution and prevention of dust adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1. The ceramic permeable brick according to the present invention is composed of a base layer and a surface layer, and the functional raw materials of the base layer and the surface layer are composed of:

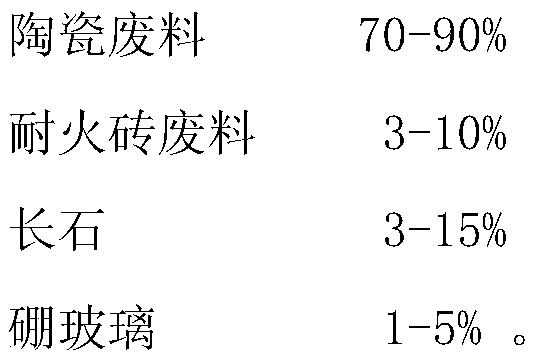

[0040] The mass percentage of functional raw materials in the matrix layer is composed of: 35% of polished brick ceramic waste with a particle size of 5-3 mm, 41% of polished brick ceramic waste with a particle size of 3-1 mm, and carbon-free refractory brick waste with a particle size of 5-3 mm 5%, particle size 3-1 mm carbon-free refractory brick waste 5%, Laiwu feldspar fine powder 12%, waste boron glass fine powder 2%.

[0041] When mixing, add 6% of carboxymethyl cellulose binder and 4% of water in the total mass of matrix layer ingredients.

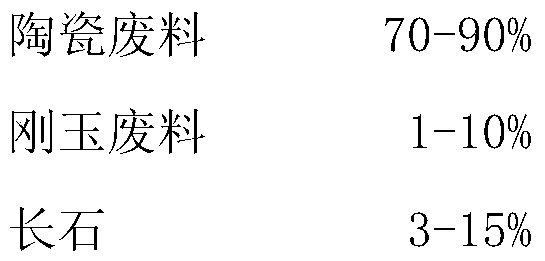

[0042] The quality percentage of surface layer functional raw materials is: 75% of polished brick ceramic waste with a particle size of 3-1 mm, 10% of corundum waste with a particle size of 3-1 mm, 12% of Laiwu ...

Embodiment 2

[0051] Embodiment 2. The ceramic permeable brick according to the present invention is composed of a base layer and a surface layer, and the functional raw materials of the base layer and the surface layer are composed of:

[0052] The mass percentage of functional raw materials in the matrix layer is composed of: 45% of polished brick ceramic waste with a particle size of 5-3 mm, 34% of polished brick ceramic waste with a particle size of 3-1 mm, and 10% of carbon-free refractory brick waste with a particle size of 3-1 mm %, new atalite fine powder 9%, waste boron glass fine powder 2%

[0053] When mixing the ingredients, 5% carboxymethyl cellulose and 4% water are added to the matrix layer.

[0054] The quality percentage of surface layer functional raw materials is: 80% of polished brick ceramic waste with a particle size of 3-1 mm, 10% of corundum waste with a particle size of 3-1 mm, 8% of new feldspar fine powder, and waste boron glass fine powder. Powder 2%.

[0055] ...

Embodiment 3

[0063] Embodiment 3. The ceramic permeable brick according to the present invention is composed of a base layer and a surface layer, and the functional raw materials of the base layer and the surface layer are composed of:

[0064] The mass percentage of functional raw materials in the matrix layer is composed of: 38% of sanitary ware ceramic waste with a particle size of 5-3 mm, 41% of polished brick ceramic waste with a particle size of 3-1 mm, and corundum refractory brick waste with a particle size of 5-3 mm 4 %, with a particle size of 3-1 mm corundum refractory brick waste 4%, Laiwu feldspar fine powder 11%, waste boron glass fine powder 2%.

[0065] When mixing, add 6% of carboxymethyl cellulose binder and 4% of water in the total mass of matrix layer ingredients.

[0066] The quality percentage of surface layer functional raw materials is: 77% of sanitary ware ceramic waste with a particle size of 3-1 mm, 8% of corundum waste with a particle size of 3-1 mm, 12% of Laiw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com