A biodegradable plastic based on polylactic acid resin

A biodegradable plastic and polylactic acid resin technology, applied in the field of plastics, can solve the problems of not significantly reducing the mechanical properties of PLA resin such as tensile strength, and achieve the effect of improving toughness and solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

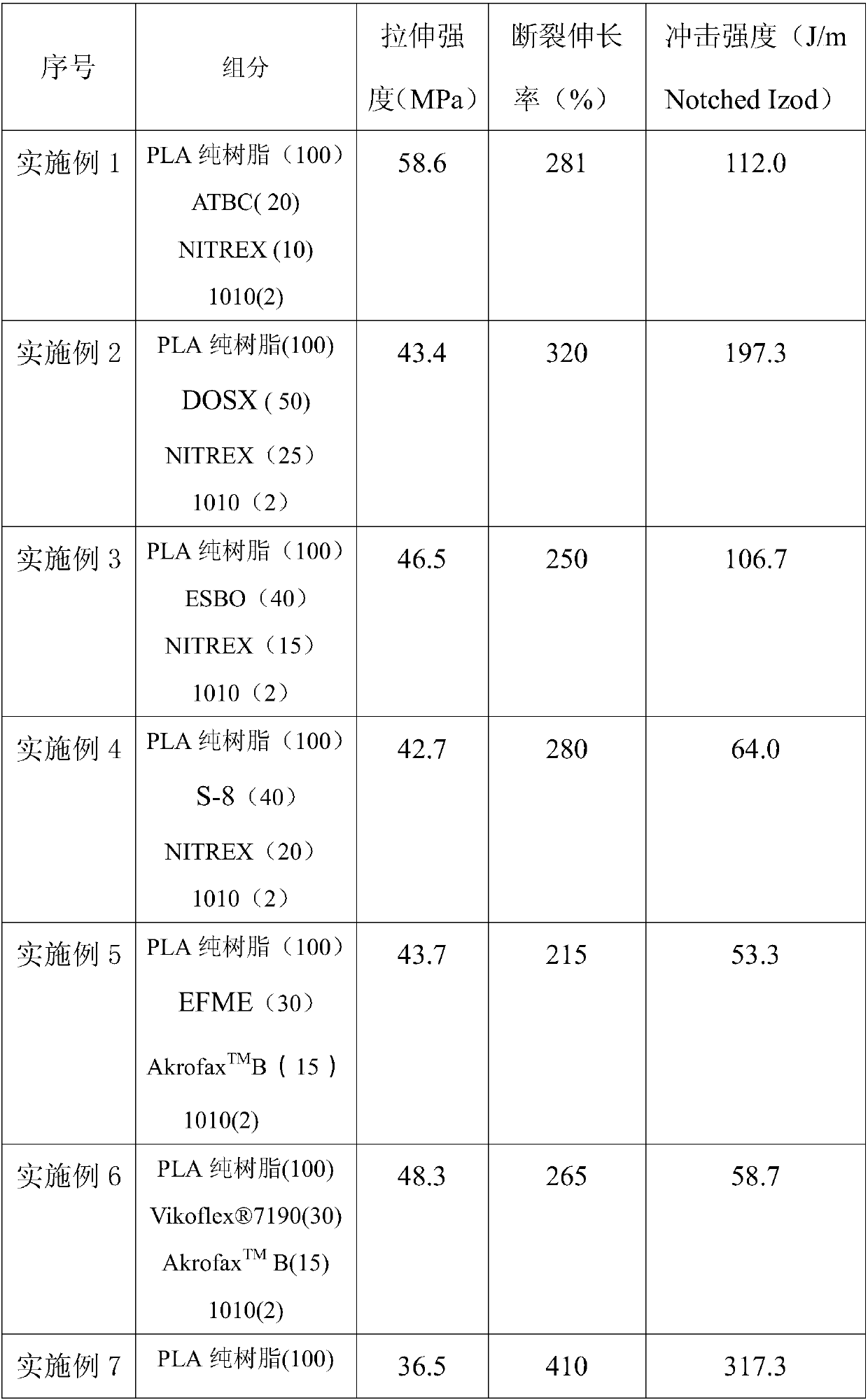

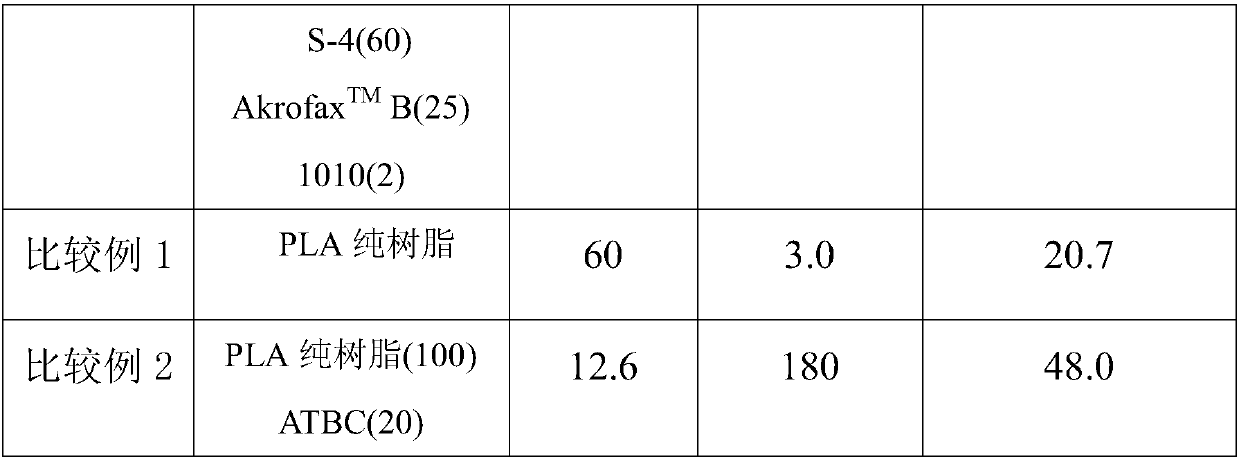

Embodiment 1

[0033] The present invention proposes a biodegradable plastic based on polylactic acid resin, which includes the following raw materials in parts by weight: 100 parts of polylactic acid resin (PLA) pure resin, 20 parts of plasticizer, 10 parts of vulcanized vegetable oil, and 2 parts of antioxidant parts, the polylactic acid resin is REVODE190, the plasticizer is ATBC, and the vulcanized vegetable oil is NITREX, the antioxidant is 1010 antioxidant, after mixing the raw materials evenly, the modified PLA plastic is produced through a twin-screw extrusion granulation production line.

Embodiment 2

[0035] The present invention proposes a biodegradable plastic based on polylactic acid resin, which includes the following raw materials in parts by weight: 100 parts of polylactic acid resin (PLA) pure resin, 50 parts of plasticizer, 25 parts of vulcanized vegetable oil, and 2 parts of antioxidant part, the polylactic acid resin (PLA) is REVODE190, the plasticizer is DOSX, and the vulcanized vegetable oil is NITREX, the antioxidant is 1010 antioxidant, after mixing the raw materials evenly, the modified PLA plastic is produced through a twin-screw extrusion granulation production line.

Embodiment 3

[0037] The present invention proposes a biodegradable plastic based on polylactic acid resin, which includes the following raw materials in parts by weight: 100 parts of polylactic acid resin (PLA) pure resin, 40 parts of plasticizer, 15 parts of vulcanized vegetable oil, and 2 parts of antioxidant part, the polylactic acid resin (PLA) is REVODE190, the plasticizer is ESBO, and the vulcanized vegetable oil is NITREX, the antioxidant is 1010 antioxidant, after mixing the raw materials evenly, the modified polylactic acid resin plastic is produced through a twin-screw extrusion granulation production line.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com