Photoinitiator for ultraviolet curing ink and preparation method and application of photoinitiator

A photo-initiator, ultraviolet light technology, applied in inks, applications, household appliances, etc., can solve problems such as low initiation efficiency, unpleasant odor, yellowing, etc., to improve initiation efficiency, improve sensitivity and absorption performance, ability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of preparation method of high-performance LED-UV photocurable ink photoinitiator, concrete operation steps are as follows:

[0034] a. Add TPO, 819, ITX and η6-cumyl ferrocene hexafluorophosphate successively to a single-necked flask equipped with a stirring device, and then place the flask in a constant temperature circulating water bath at 2°C for uniform mixing. In the process, the stirring device is turned on, and the mechanical stirring state is maintained to fully and evenly mix the initiator, and the stirring is mixed for 1 hour;

[0035] b. According to the basic theory of modification, cationic photoinitiators are sequentially added to the single-necked flask, firstly add UVI-6992 to the flask, stir and mix for 10 minutes; add η6-cumyl ferrocene hexafluorophosphate to In the system, keep the constant temperature water bath at 2°C, stir and mix for 30 minutes;

[0036] c. Add cobalt acetylacetonate into a single-necked flask, mix and stir for 15 minutes,...

Embodiment 1

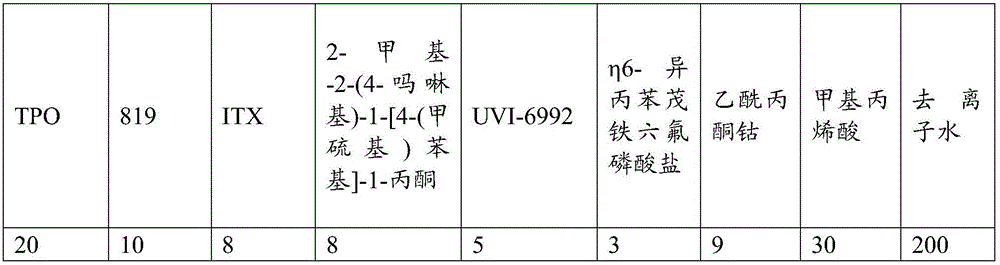

[0050] Prepare a kind of photoinitiator that is applicable to ultraviolet curing ink, the compound ratio used in embodiment one is as shown in the following table:

[0051] The proportioning (g) of compound used in the embodiment one of table 1

[0052]

[0053]

[0054] The preparation method is as follows:

[0055] a. Add TPO, 819, ITX and η6-cumyl ferrocene hexafluorophosphate successively to a single-necked flask equipped with a stirring device, and then place the flask in a constant temperature circulating water bath at 2°C for uniform mixing. In the process, the stirring device is turned on, and the mechanical stirring state is maintained to fully and evenly mix the initiator, and the stirring is mixed for 1 hour;

[0056] b. According to the basic theory of modification, cationic photoinitiators are sequentially added to the single-necked flask, firstly add UVI-6992 to the flask, stir and mix for 10 minutes; add η6-cumyl ferrocene hexafluorophosphate to In the s...

Embodiment 2

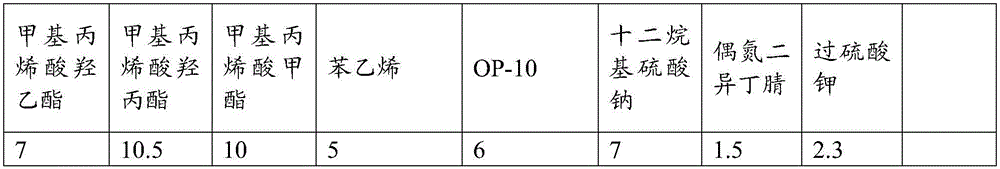

[0068] Prepare a kind of photoinitiator that is applicable to ultraviolet curing ink, the compound ratio used in embodiment one is as shown in the following table:

[0069] The proportioning (g) of compound used in the embodiment two of table 2

[0070]

[0071] The preparation method is as follows:

[0072] a. Add TPO, 819, ITX and η6-cumyl ferrocene hexafluorophosphate successively to a single-necked flask equipped with a stirring device, and then place the flask in a constant temperature circulating water bath at 2°C for uniform mixing. In the process, the stirring device is turned on, and the mechanical stirring state is maintained to fully and evenly mix the initiator, and the stirring is mixed for 1 hour;

[0073] b. According to the basic theory of modification, cationic photoinitiators are sequentially added to the single-necked flask, firstly add UVI-6992 to the flask, stir and mix for 10 minutes; add η6-cumyl ferrocene hexafluorophosphate to In the system, keep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com