A kind of demulsifier for treating aging oil and its application

A demulsifier and aging oil technology, which is applied in the treatment of hydrocarbon oil, dehydration/demulsification by chemical methods, and only multi-stage serial refining process treatment, etc. It can solve the complex composition of aging oil, no chemical composition, and difficult treatment, etc. problem, to achieve good demulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

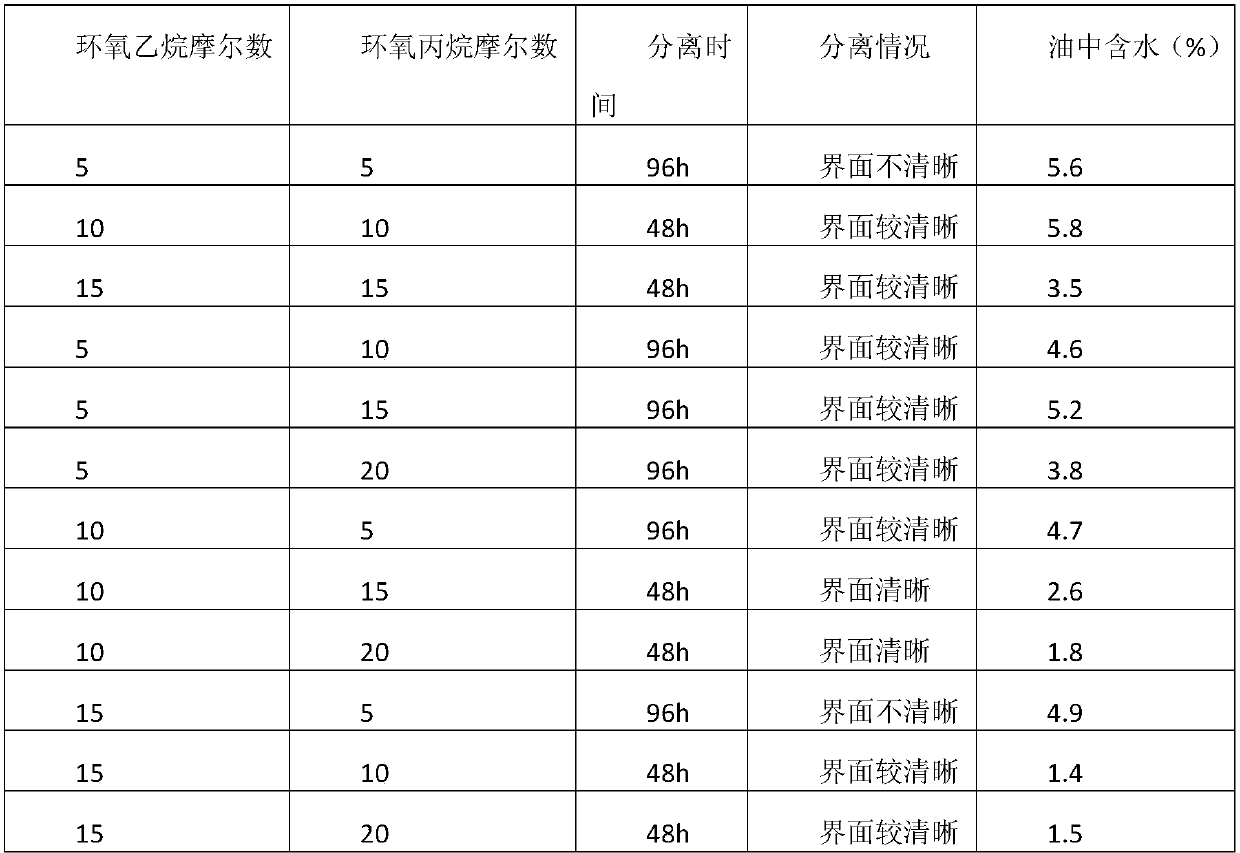

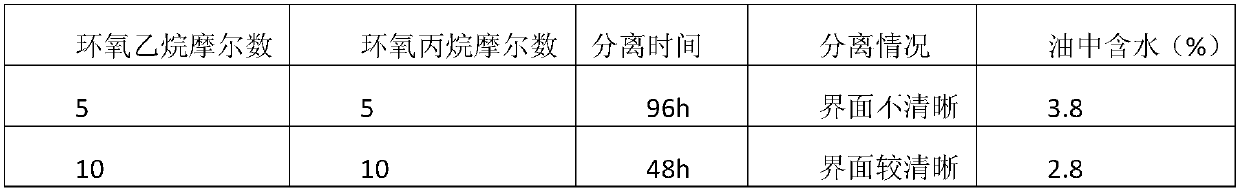

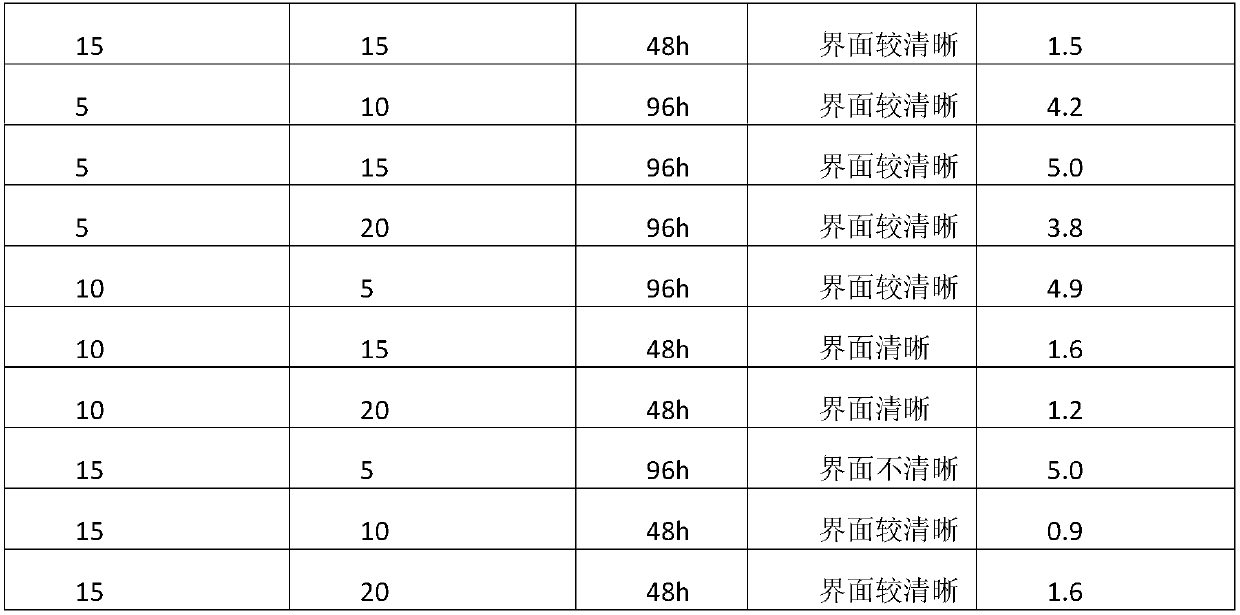

[0012] Synthesis of demulsifiers

[0013] Put a certain amount of dodecylamine or octadecylamine and catalyst (KOH or NaOH) into the reaction kettle, the amount of catalyst added is 0.1%-0.3% of the amine, replace the air in the kettle with nitrogen, at 105-110°C, Dehydrate for about 30 minutes. Continue to raise the temperature, and feed a metered amount of propylene oxide at 135-145°C and a pressure of 0.1-0.3 MPa to make the amine react with propylene oxide first. Pass through propylene oxide, and when the pressure drops to about 0MPa, then add catalyst (KOH or NaOH), the amount of catalyst added is 0.1%-0.3% relative to the mass of amine, and then pass through ethylene oxide to continue Reaction, reaction temperature l20-135 ℃, pressure 0.05-0.2MPa. When the metered ethylene oxide is passed through and the pressure drops to about 0MPa, keep it warm for 30 minutes and neutralize it with acid, then the demulsifier is finished.

[0014] The ring-opening reaction of propyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com