Double layer multi-strand wire prepared fiber rod and preparation method

A fiber rod and double-layer technology, applied in the fiber field, can solve the problems of low water absorption of fiber rods, impact on service life, loose fiber filaments, etc., and achieve the effect of strong capillary water absorption and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

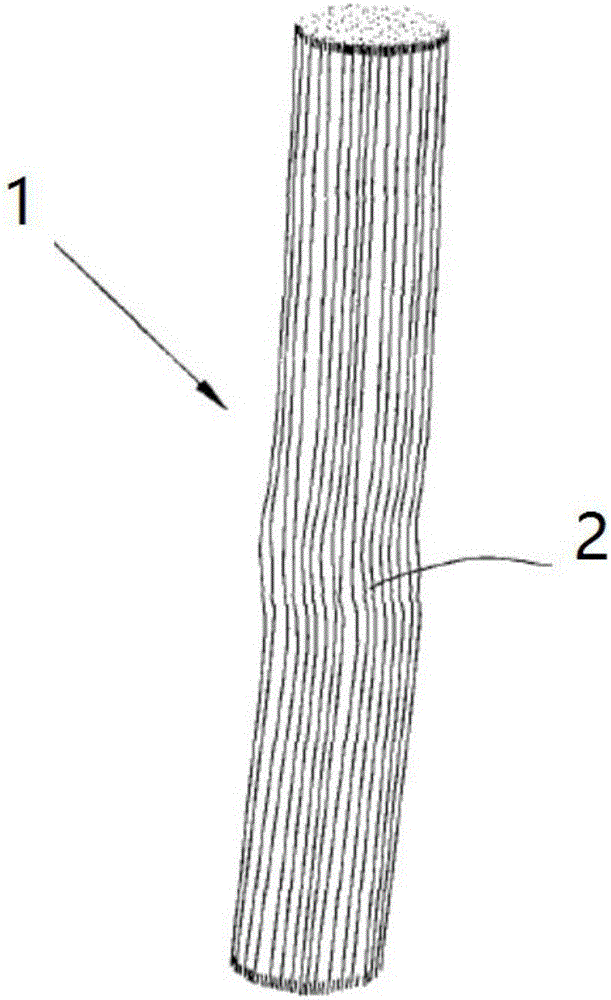

[0021] Please refer to Figure 1 to Figure 4 As shown, a method for making fiber rods from double-layer multi-strand filaments,

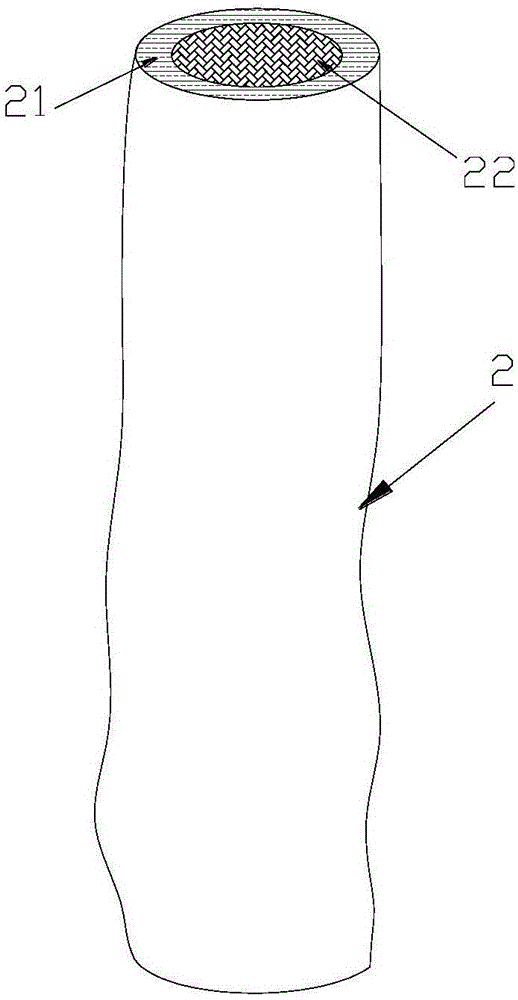

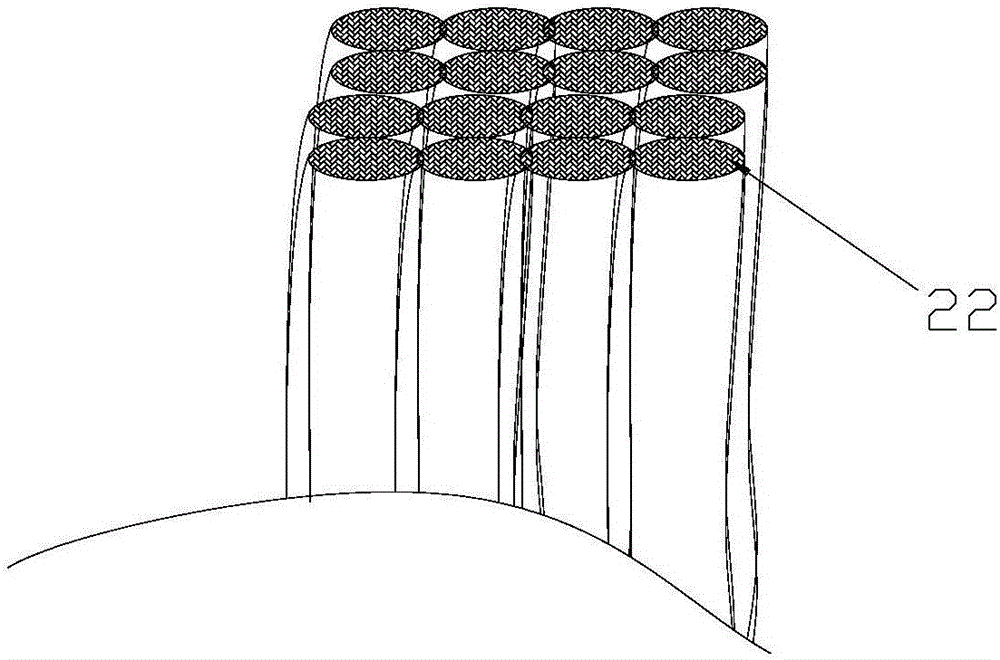

[0022] Step 1: Feed, input a plurality of double-layer multi-strand filaments 1, each double-layer multi-strand filament 1 includes a plurality of single-strand fiber filaments 2, and the single-strand fiber filament 2 includes an outer layer 21 and an inner core layer 22, Outer layer 21 is wrapped on inner core layer 22 outer surface, and outer layer 21 is the low melting point outer layer that is made of PE (polyethylene) material, and inner core layer 22 is the high melting point layer that is made of PP (polypropylene) material. Inner core layer, the melting point of the outer layer is lower than the melting point of the inner core layer;

[0023] Step 2: Double-layer multi-strand yarn 1 is texturized by a texturing machine so that the fibers form DTY fiber threads with better pores and bulkiness;

[0024] Step 3: warping and plying a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com