Collapsible loess foundation rubble frame structure reinforcement system and reinforcement method

A technology of collapsible loess and frame structure, which is applied in basic structure engineering, soil protection, construction, etc., can solve problems such as poor engineering geological characteristics, influence on building safety, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

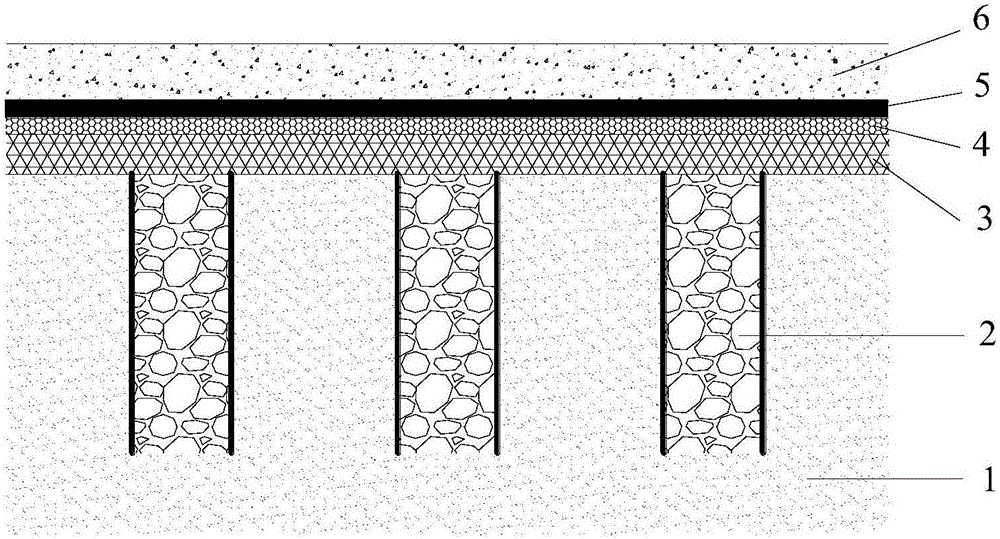

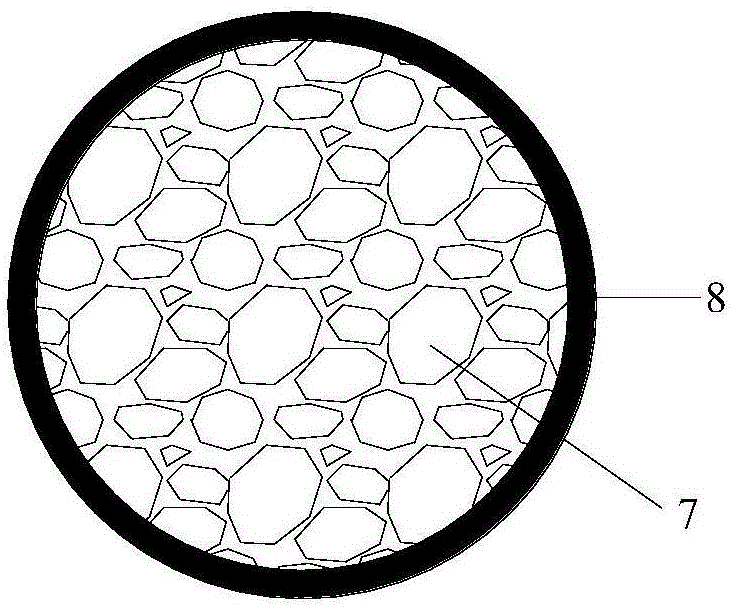

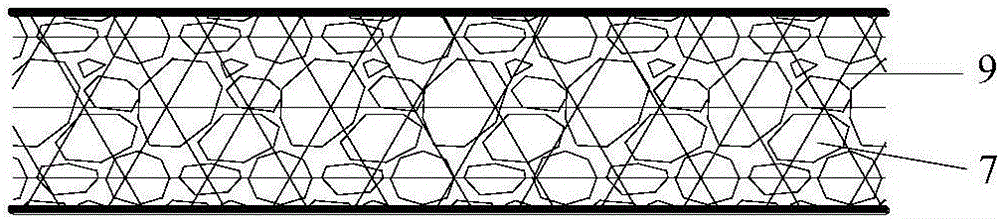

[0045] Such as Figure 1~4 As shown, a collapsible loess foundation crushed stone frame structure reinforcement system includes collapsible loess base 1, reinforced crushed stone pile 2, geocell reinforced crushed stone layer 3, EVA waterproof board 4, geotextile Cushion layer 5 and concrete surface layer 6; wherein, reinforced gravel pile 2, geocell reinforced gravel layer 3, EVA waterproof board 4, geotextile cushion layer 5 and concrete surface layer 6 are arranged sequentially from bottom to top; The reinforced gravel pile 2 and the geocell reinforced gravel layer 3 are jointly grouted through the pre-embedded grouting pipe 10 to form an integral frame structure reinforcement system.

[0046] The reinforced gravel pile 2 has a diameter of 1.0 m, a length of 3 m, and is arranged in a quincunx shape with a horizontal spacing of 5 m; the tensile strength of the geogrid sleeve 8 is 50 kN / m, and the width is 3 m. The thickness of the geocell reinforced gravel layer 3 is 30 cm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com