High-precision laser divergence angle parameter calibration device

A technology for parameter calibration and divergence angle, which is used in measurement devices, optical instrument testing, and optical performance testing. The effect of small measurement uncertainty and simple experimental operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

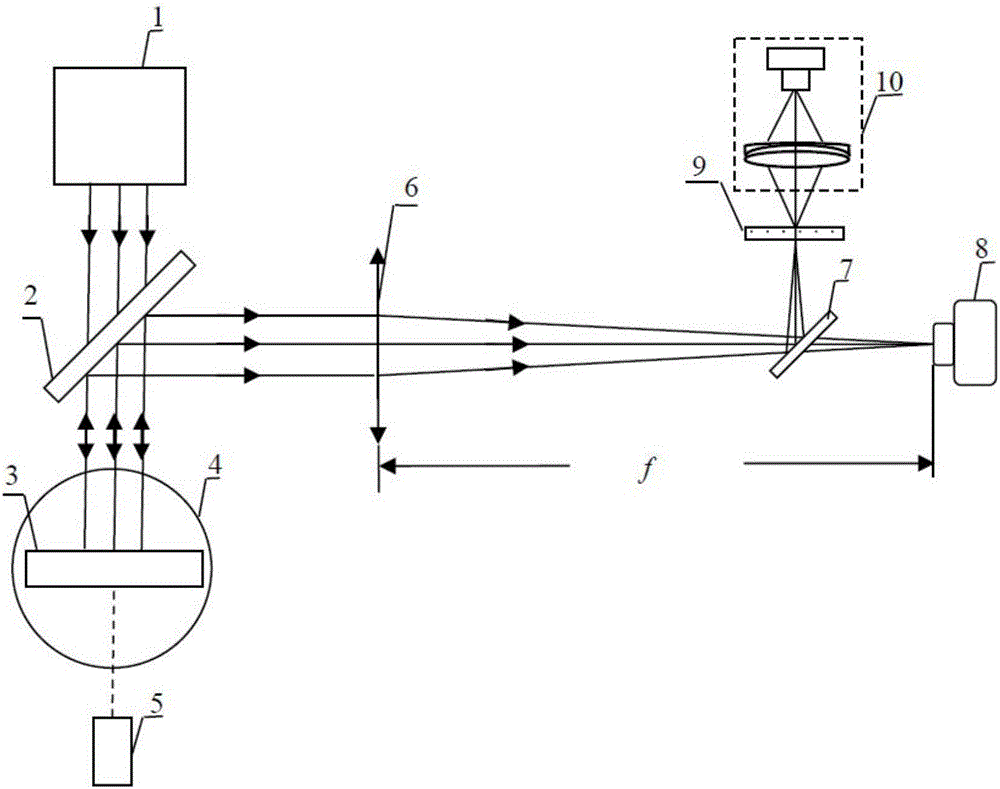

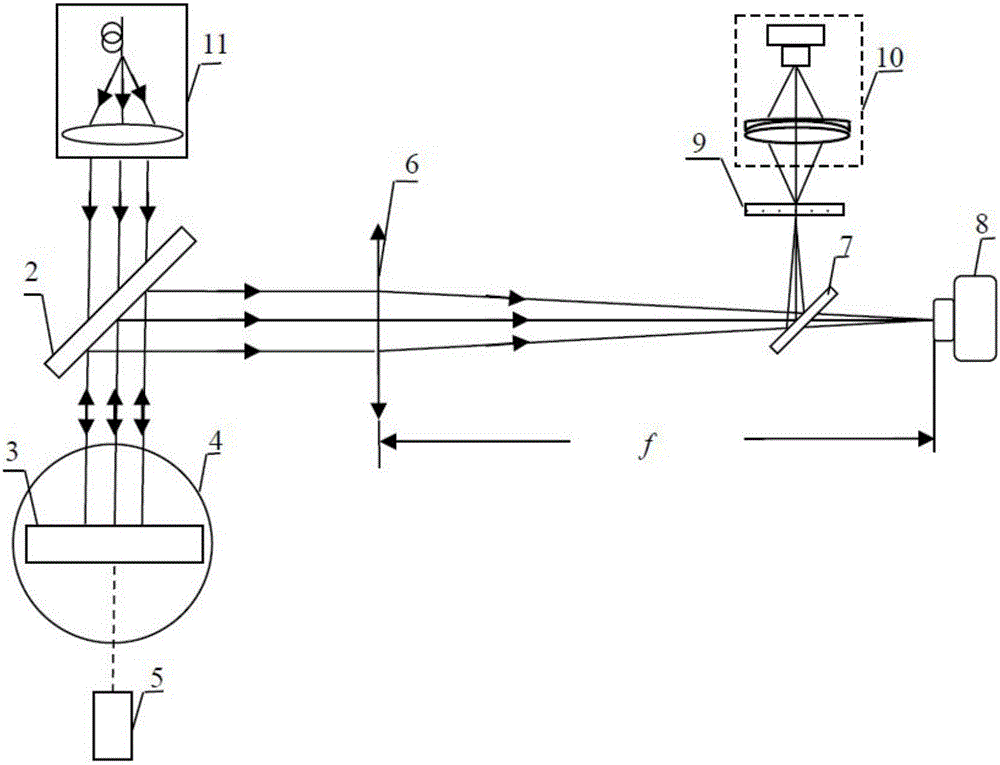

[0045] refer to figure 1 . In the embodiments described below, the calibration of laser divergence angle parameters can be completed.

[0046] The high-precision laser divergence angle parameter calibration device in this embodiment includes: a laser to be measured 1, a beam splitter 2, a flat crystal 3, a precision rotary table 4, an electronic autocollimator 5, a focusing lens 6, a beam splitter 7, and a CCD camera 8 , ground glass screen 9 and imaging system 10.

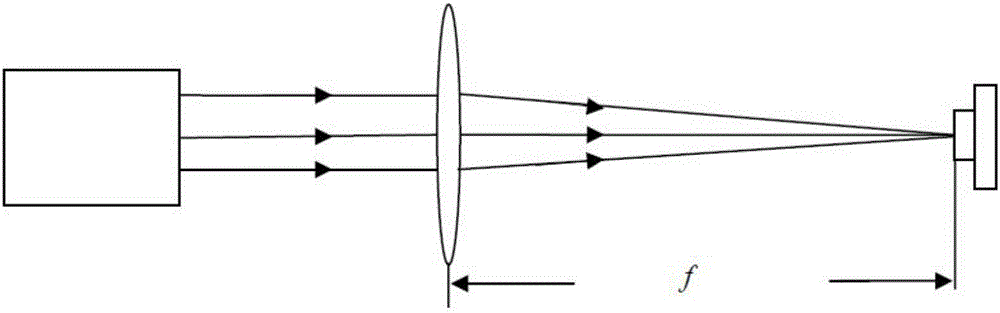

[0047] The laser light 1 to be tested is reflected by the flat crystal 3 and the beam splitter 2 and then focused by the focusing lens 6. The converged light is divided into two test light paths of transmission and reflection after passing through the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com