Resistance changing agent for changing soil resistance

A technology of soil resistance and resistive agent, which is applied in the direction of conductive materials, circuits, electrical components, etc. dispersed in non-conductive inorganic materials, and can solve problems such as poor resistance reduction ability, change of soil resistivity, soil pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-18

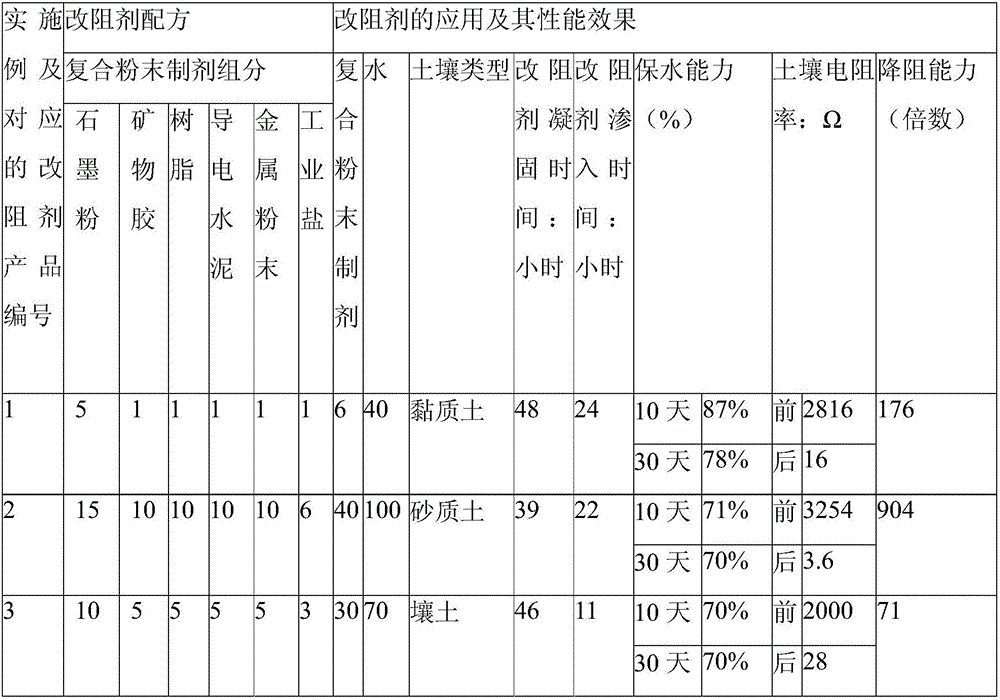

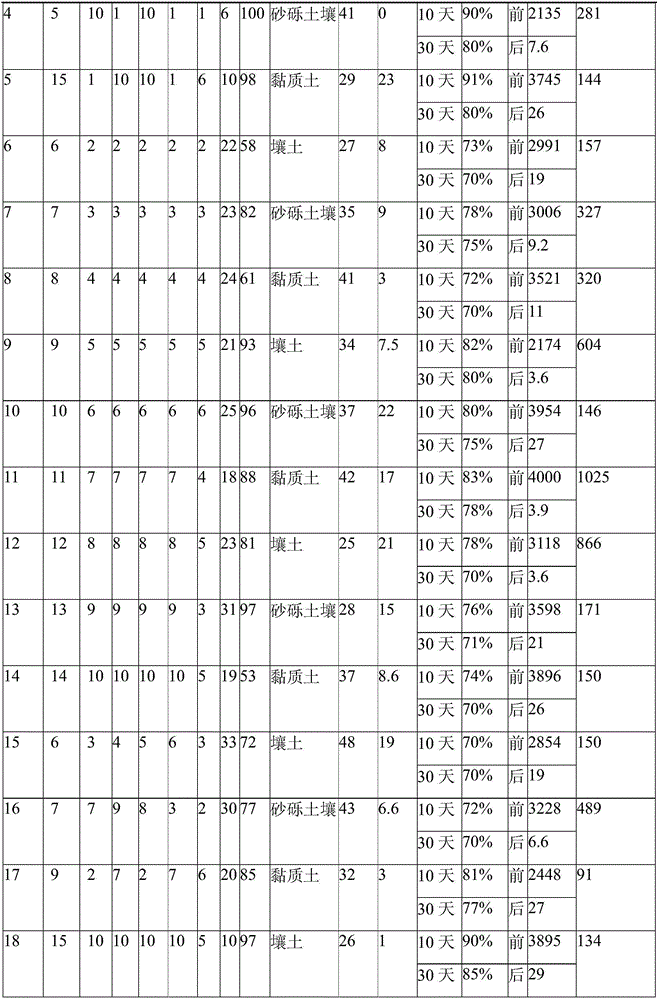

[0063] Embodiment 1-18. No. 1-18 resistance modifying agent of the present invention and its application effect

[0064] Embodiment 1-18 provides multiple specific formulations of the conductive anticorrosion coating described in the protection scope of the present invention, as shown in Table 1 below, in the table, each raw material component, the composite powder preparation of each raw material component, and water are all In parts by weight.

[0065]

[0066]

[0067] In all the above embodiments, the application steps of the resistance modifying agent include: selecting the soil area to be tested, and measuring the soil resistance of the area; after mixing the above-mentioned raw materials and components according to the corresponding weight ratio, Pour into the above soil area, and measure the soil resistance again after 24 hours;

[0068] The performance test method of described resistance changing agent is as follows:

[0069] When the resistance-modifying agen...

Embodiment 19

[0073] Example 19, using the resistance-modifying agent of the present invention to improve soil resistance

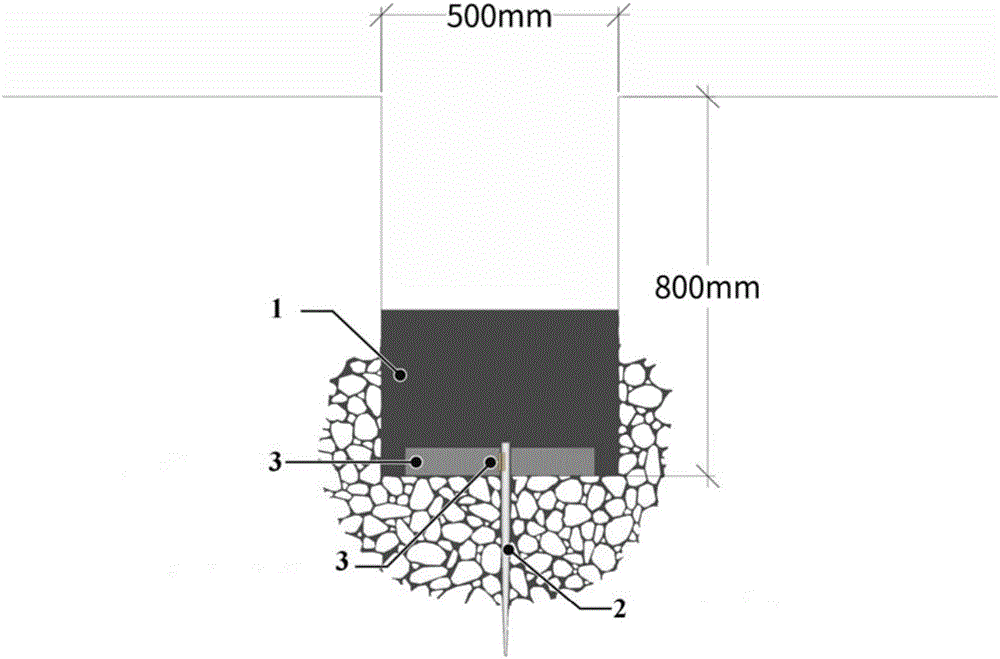

[0074] This embodiment provides a method for changing soil resistance, such as figure 1 shown, including the following steps:

[0075] Dig the trench; set up the grounding device; according to the soil type, select a resistance-modifying agent formula in Examples 1-18, mix all the raw materials to obtain a composite powder preparation, and fill and pour the composite powder preparation And / or scattered in the soil; backfill the soil after 24 hours; the grounding device can be the grounding pole 2 and / or the grounding module 3 .

[0076] Alternatively, after obtaining the composite powder preparation, mix 6-40 parts by weight of the above-mentioned composite powder preparation with 40-100 parts by weight of water, then perform the filling, pouring and / or spreading, and finally backfill the soil.

[0077]After 24-48 hours of filling the soil with resistance modifying a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com