Sodium super ionic conductor-inlaid and coated positive electrode material for sodium-ion battery and synthesis method of positive electrode material

A sodium ion battery and ion conductor technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor material storage performance, need to enhance the rate performance, side reactions, etc., to achieve interface stability improvement, sodium ion diffusion The effect of improving ability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Measure 90ml PEG-400 and place it in a 200ml beaker, place the beaker on a magnetic stirrer and stir, then add the weighed 0.004mol Ti 3 (PO 4 ) 4 , while adding and stirring, after stirring and dispersing for 30min, the weighed 0.3molNaNi 0.5 Mn 0.5 O 2 Add to the above solution, continue to stir for 10min, transfer the solution in the beaker to a 100ml reaction kettle, carry out a solvothermal reaction at 180°C for 12h in a blast drying oven, and after cooling down naturally, place the product in a vacuum drying oven at 180°C. Vacuum drying at 80°C, place the obtained powder in a corundum porcelain boat, transfer the corundum porcelain boat to a muffle furnace, and calcine at 700°C for 8 hours in an air atmosphere. The product obtained is NaTi, a fast ion conductor. 2 (PO 4 ) 3 Mosaic-coated NaNi 0.5 Mn 0.5 O 2 positive electrode material.

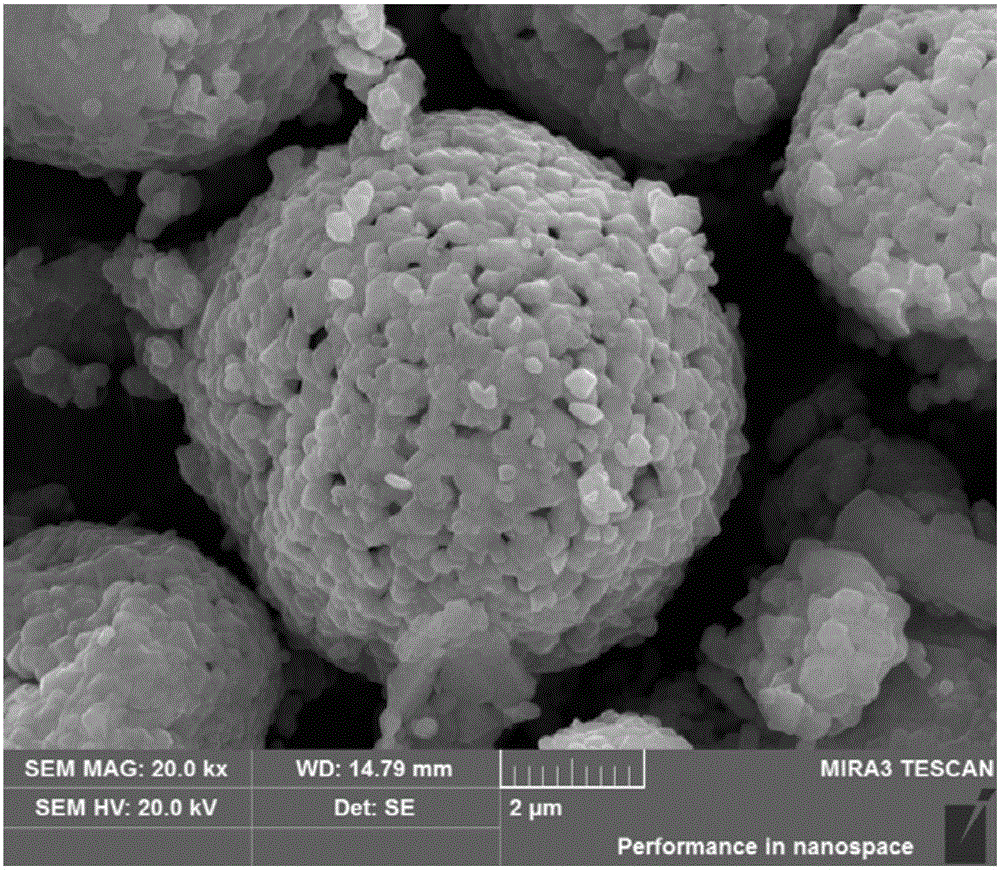

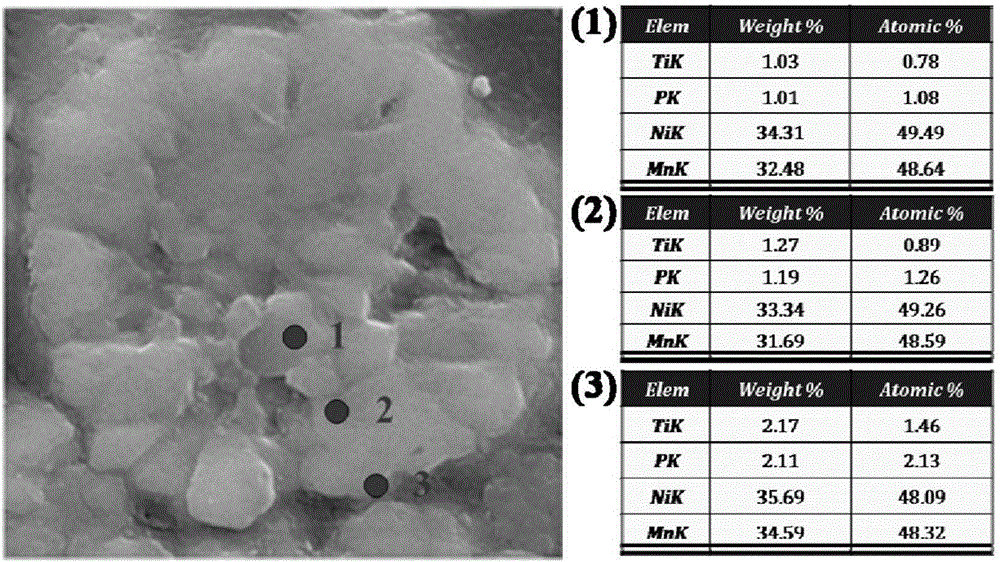

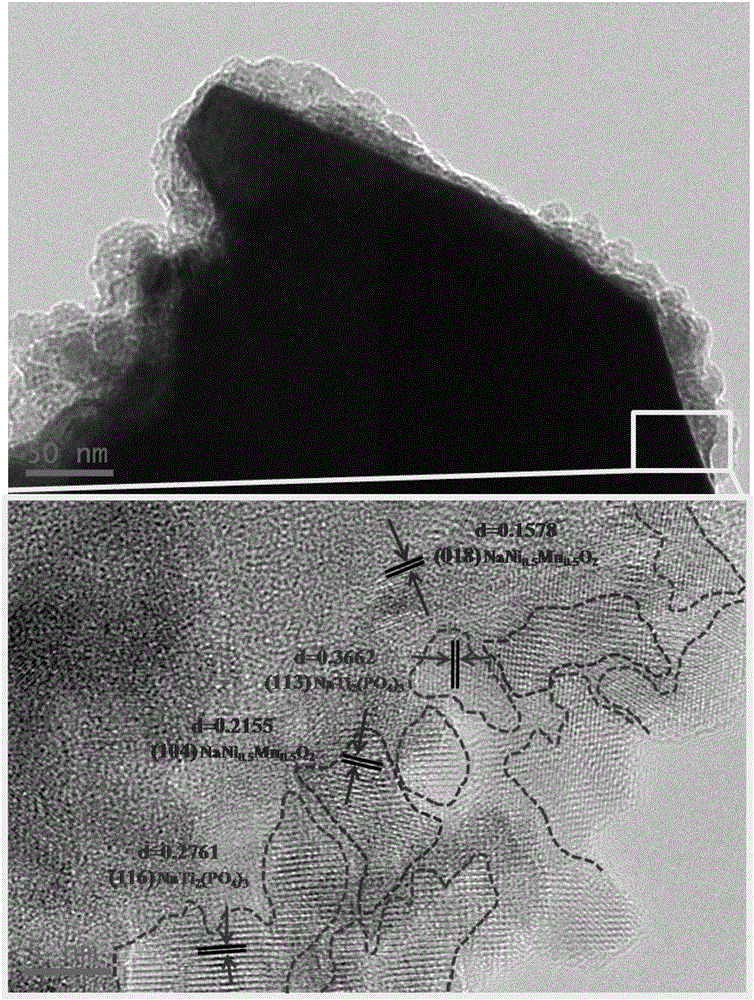

[0031] The particle morphologies of the synthesized materials were observed by scanning electron microscopy (e.g. fig...

Embodiment 2

[0033] Measure 90ml of PEG-400 and place it in a 200ml beaker, place the beaker on a magnetic stirrer and stir, then add the weighed 0.002mol Ti (CH 3 COO) 2 ·4H 2 O and 0.006mol NH 4 H 2 PO 4 , while adding and stirring, after stirring and dispersing for 30min, the weighed 0.3mol NaNi 0.5 Mn 0.5 O 2 Add to the above solution, continue to stir for 10min, transfer the solution in the beaker to a 100ml reaction kettle, and carry out a solvothermal reaction at 100°C for 12h in a blast drying oven. After cooling down naturally, the product is placed in a vacuum drying oven at Vacuum drying at 80 °C, the obtained powder is placed in a corundum porcelain boat, the corundum porcelain boat is transferred to a muffle furnace, and the product is calcined at 500 °C for 8 hours in an air atmosphere. NaTi 2 (PO 4 ) 3 Mosaic-coated NaNi 0.5 Mn 0.5 O 2 positive electrode material.

[0034] The particle morphology of the synthesized material was observed by scanning electron mic...

Embodiment 3

[0036] Measure 90ml of PEG-400 and place it in a 200ml beaker, place the beaker on a magnetic stirrer and stir, then add the weighed 0.002mol Ti 3 (PO 4 ) 4 , while adding and stirring, after stirring and dispersing for 30min, the weighed 0.3molNaNi 0.5 Ti 0.5 O 2 Add to the above solution, continue to stir for 10min, transfer the solution in the beaker to a 100ml reaction kettle, carry out a solvothermal reaction at 180°C for 12h in a blast drying oven, and after cooling down naturally, place the product in a vacuum drying oven at 180°C. Vacuum drying at 80°C, place the obtained powder in a corundum porcelain boat, transfer the corundum porcelain boat to a muffle furnace, and calcine it at 700°C for 8 hours in an air atmosphere. The resulting product is an in-situ synthesized sodium fast ion conductor. NaTi 2 (PO 4 ) 3 Mosaic-coated NaNi 0.5 Ti 0.5 O 2 positive electrode material.

[0037] The particle morphology of the synthesized material was observed by scanning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com