A molecular cracking pulse driver

A driver and cracking reactor technology, applied in the direction of electric pulse generator circuit, pulse technology, pulse generation, etc., can solve the problems of strong electromagnetic interference of cracking unit and increase the cost of components, so as to reduce the cost of manpower and material resources and reduce the maintenance cost. , the effect of low energy burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

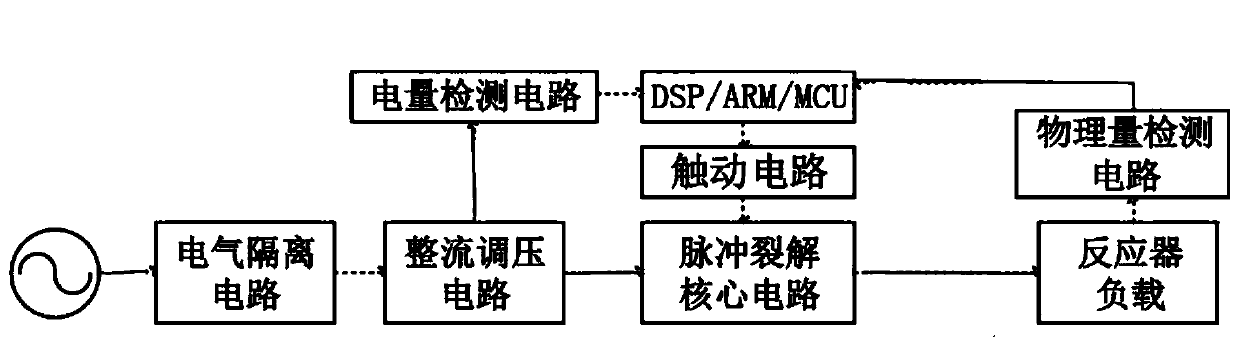

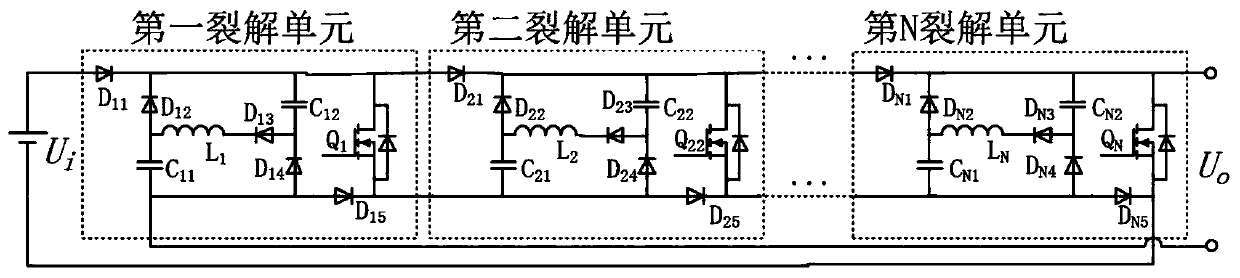

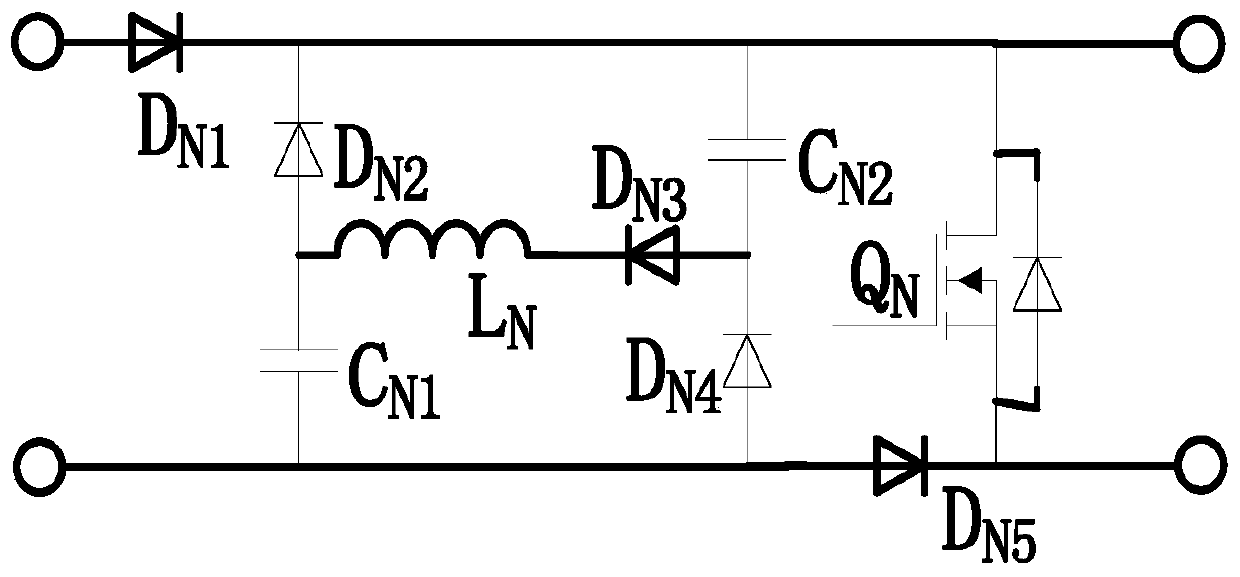

[0020] Such as figure 1 As shown, a molecular cracking pulse driver includes an electrical isolation circuit, a rectification and voltage regulation circuit, a pulse cracking core circuit and a cracking reactor, the mains power is input to the electrical isolation circuit, and the electrical isolation circuit is connected to the rectification and voltage regulation circuit, The rectification and voltage regulation circuit is connected with the pulse cracking core circuit, the pulse cracking core circuit is connected with the cracking reactor load, the rectification and voltage regulation circuit is connected with a power detection circuit, and the power detection circuit is connected with the digital signal processing device or ARM processor or microcontroller, the digital signal processor or ARM processor or microcontroller is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com