Conical roller type peony seed shelling and cleaning device

A cleaning device and a technology of conical drum, which are applied in the direction of shelling, separating solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of increasing labor cost, difficult shelling, and difficulty in shell removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

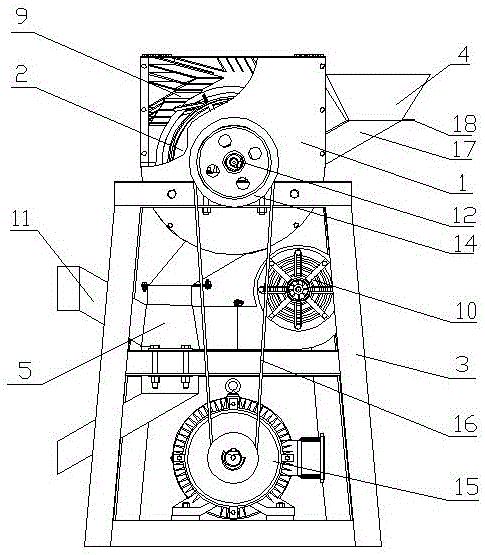

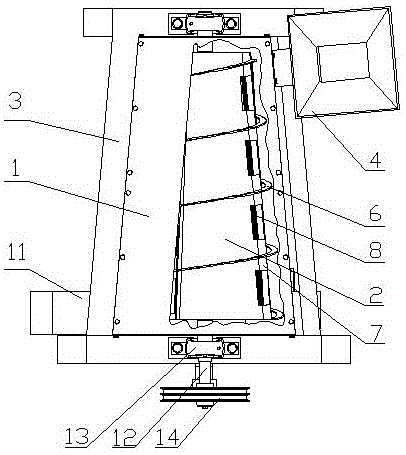

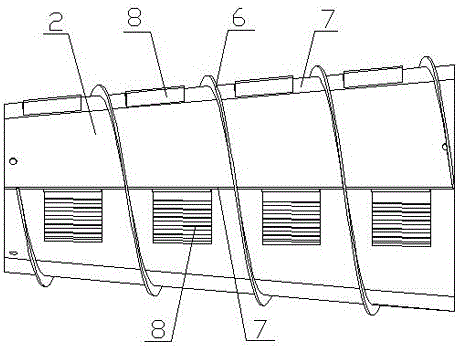

[0023] like Figure 1 to Figure 4 As shown in the figure, in a conical drum type peony seed shelling and cleaning device of the present invention, after the material enters the casing 1, the shelling and separation are completed in the process of conveying to the discharge port on the casing 1, and then pass through Wind-selected and hulled, the final result is whole kernels. The present invention includes a casing 1 , a conical drum 2 , a frame 3 and a fan 10 . In this embodiment, the upper half of the casing 1 is a trapezoidal casing, and the lower half of the casing 1 is arranged to be connected with the conical drum. The semi-conical shell with the same taper of shell 2 has two upper and lower feeding ports on the side wall of the rectangular shell of shell 1, which is close to the end of the semi-conical shell with the smaller diameter of shell 1, so that the material can be fed. The entry into the casing 1 is more uniform, and the material blockage is not easy to occur....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com