A kind of Bianstone auricular point pressure bean

A Bianstone ear and bean pressing technology, which is applied in the field of medical equipment, can solve the problems of low far-infrared normal emissivity and poor product performance, and achieve the effects of promoting microcirculation, moderate hardness, and good health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

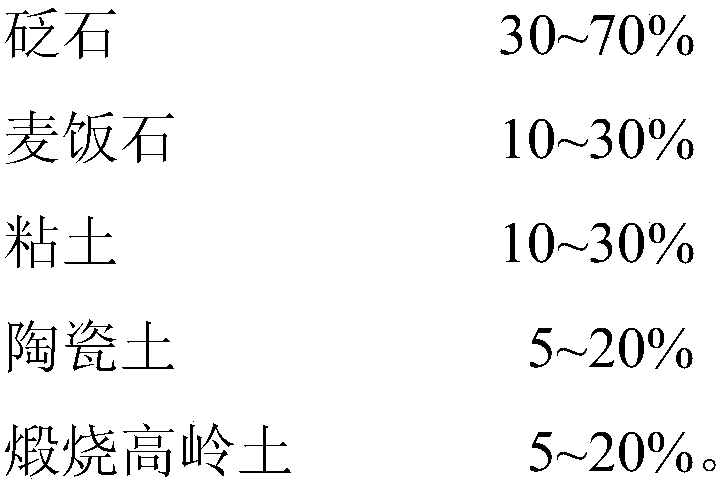

[0020] An auricular pressure bean, which is made of the following raw materials in weight ratio:

[0021]

[0022] The preparation method is as follows:

[0023] 1) Weigh the meteorite, medical stone, clay, ceramic clay, and calcined kaolin according to the weight ratio, and grind them together through a 300-mesh sieve and mix evenly, and then add carboxymethyl fiber with a mass concentration of 0.5% to the mixed powder plain sodium solution and stirred to make soft material;

[0024] 2) Extrude the soft material onto a spheronizer, control the rotation speed of the spheronizer to 3000 rpm, and the drying temperature to 80°C to make spherical pellets with a particle size of 3mm and a bulk density of 4.5g / ml;

[0025] 3) Put the spherical pellets in a kiln at 700°C for firing and activation, take them out of the furnace after 3 hours, and cool down naturally;

[0026] 4) adding liquid paraffin for polishing treatment, that is.

Embodiment 2

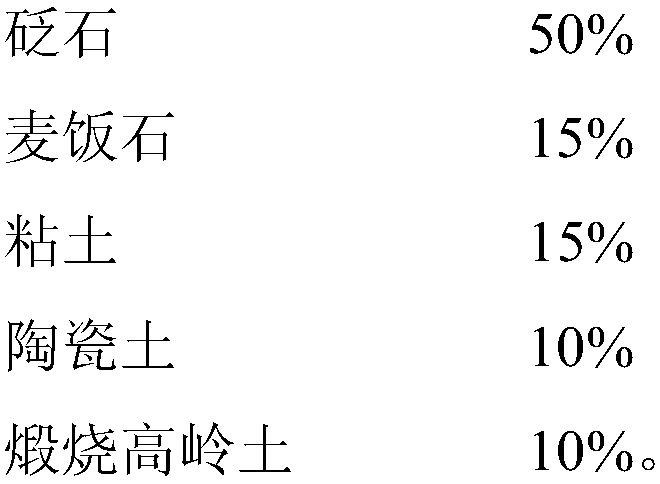

[0028] An auricular pressure bean, which is made of the following raw materials in weight ratio:

[0029]

[0030]

[0031] The preparation method is as follows:

[0032] 1) Weigh the meteorite, medical stone, clay, ceramic clay, and calcined kaolin according to the weight ratio, and grind them together through a 200-mesh sieve and mix evenly, and then add carboxymethyl fiber with a mass concentration of 2% to the mixed powder plain sodium solution and stirred to make soft material;

[0033] 2) Extrude the soft material onto a spheronizer, control the rotation speed of the spheronizer to 5000 rpm, and the drying temperature to 60°C to make spherical pellets with a particle size of 5mm and a bulk density of 7g / ml;

[0034] 3) Put the spherical pellets in a kiln at 800°C for firing and activation, take them out of the furnace after 1 hour, and cool down naturally;

[0035] 4) adding liquid paraffin for polishing treatment, that is.

Embodiment 3

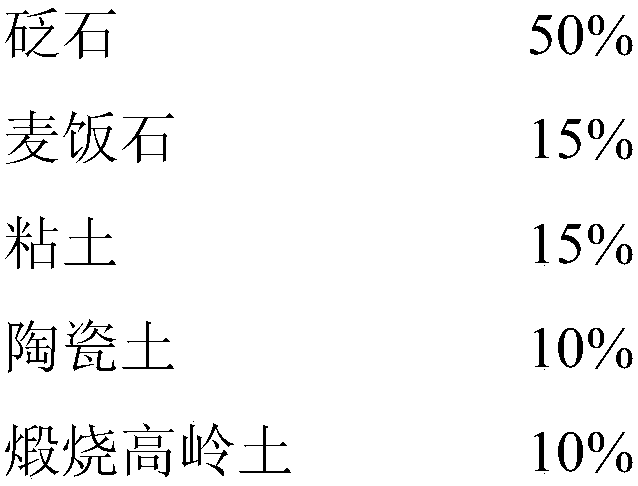

[0037] An auricular pressure bean, which is made of the following raw materials in weight ratio:

[0038]

[0039] The preparation method is as follows:

[0040] 1) Weigh the meteorite, medical stone, clay, ceramic clay, and calcined kaolin according to the weight ratio, pulverize them together and pass through a 400-mesh sieve and mix evenly, then add carboxymethyl fiber with a mass concentration of 0.1% to the mixed powder plain sodium solution and stirred to make soft material;

[0041] 2) Extrude the soft material onto a spheronizer, control the speed of the spheronizer to 2000 rpm, and the drying temperature to 120°C to make spherical pellets with a particle size of 1mm and a bulk density of 2g / ml;

[0042] 3) Put the spherical pellets in a kiln at 500°C for firing and activation, take them out of the furnace after 5 hours, and cool down naturally;

[0043] 4) adding liquid paraffin for polishing treatment, that is.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com