An electric spark fluid atomizing nozzle

An atomizing nozzle and electric spark fluid technology, applied in the field of EDM, can solve the problems of low processing efficiency, increased probability of abnormal discharge, and reduced pulse utilization rate, so as to improve the surface quality of the workpiece and change the configuration of the discharge channel. , Improve the effect of atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

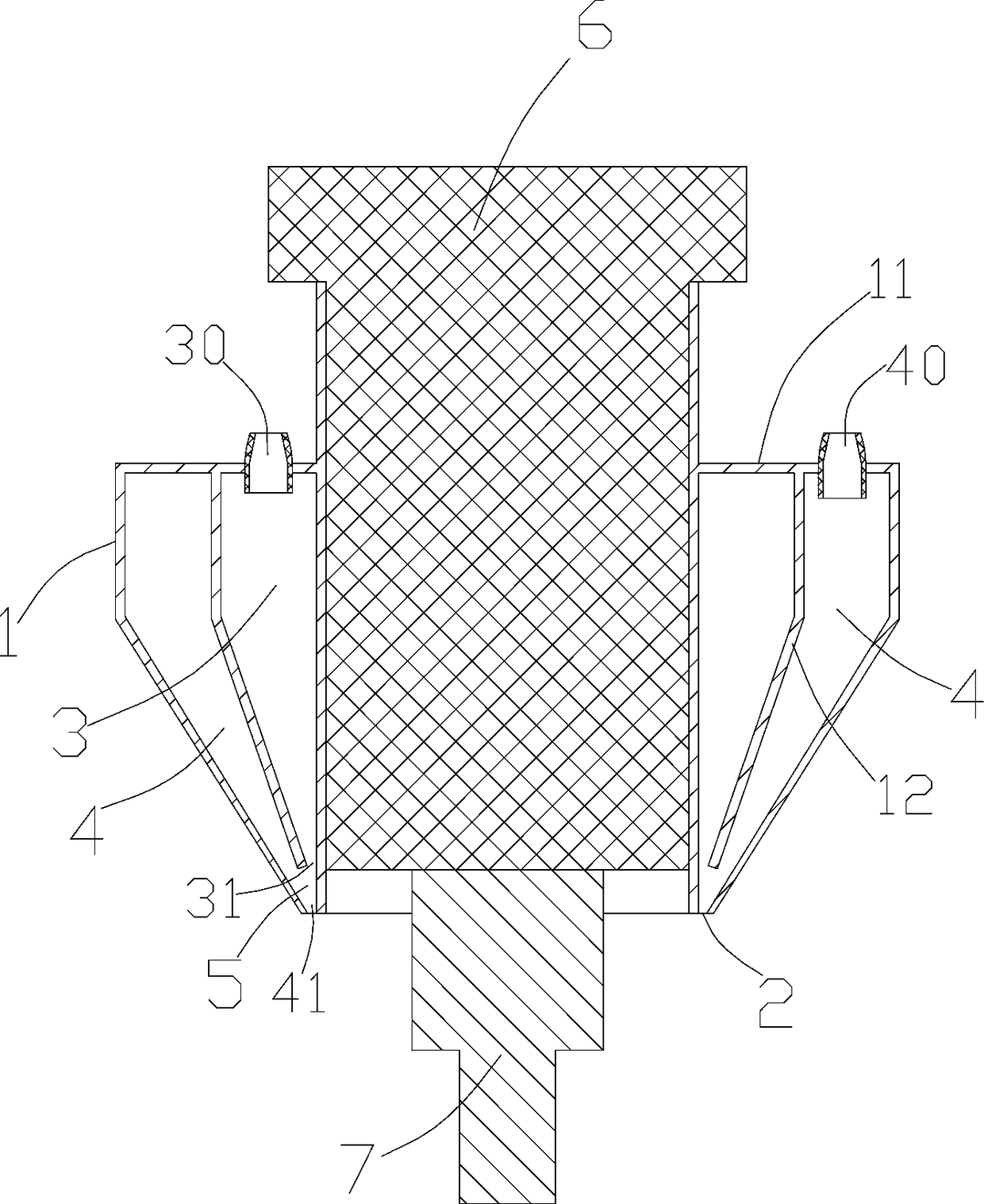

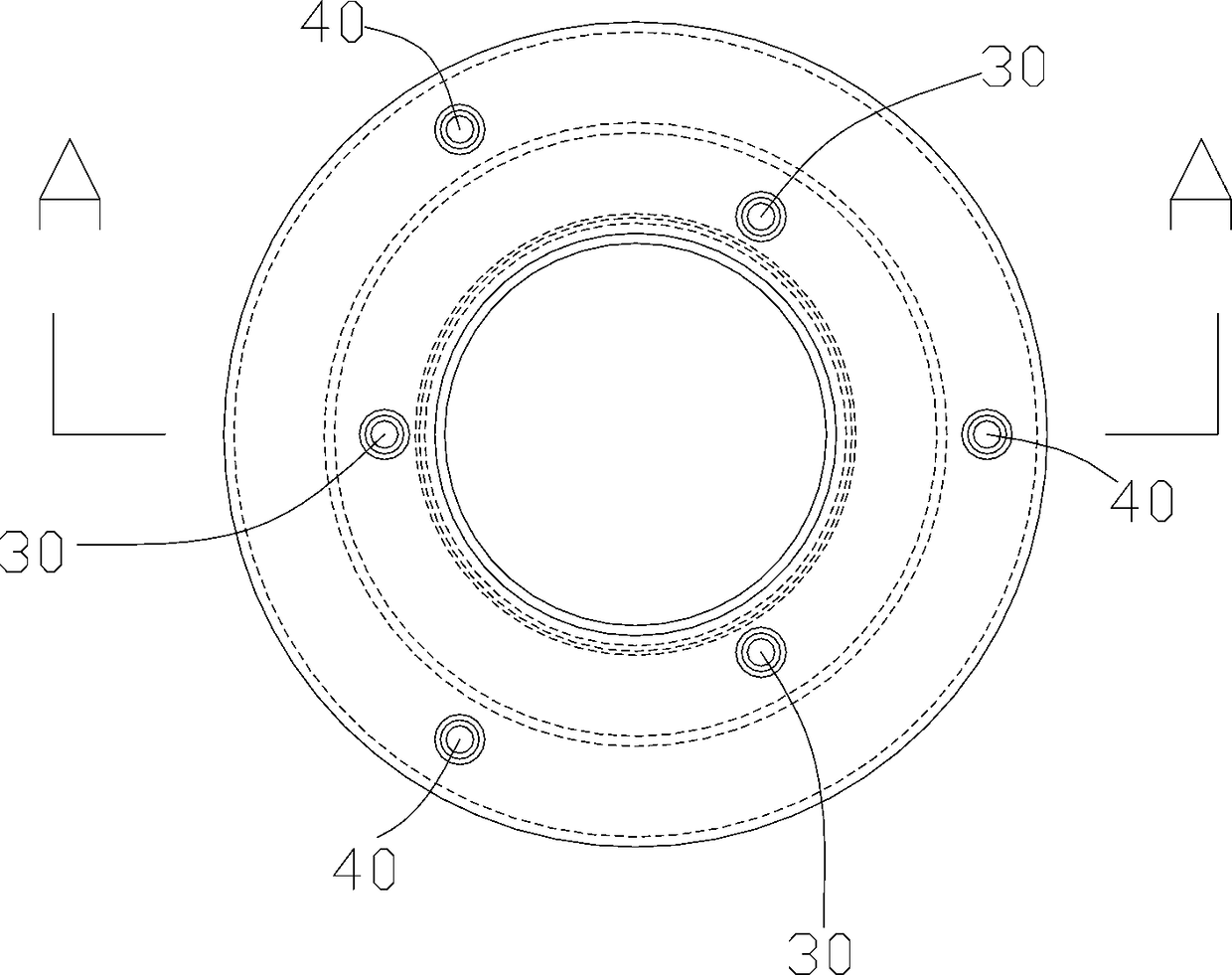

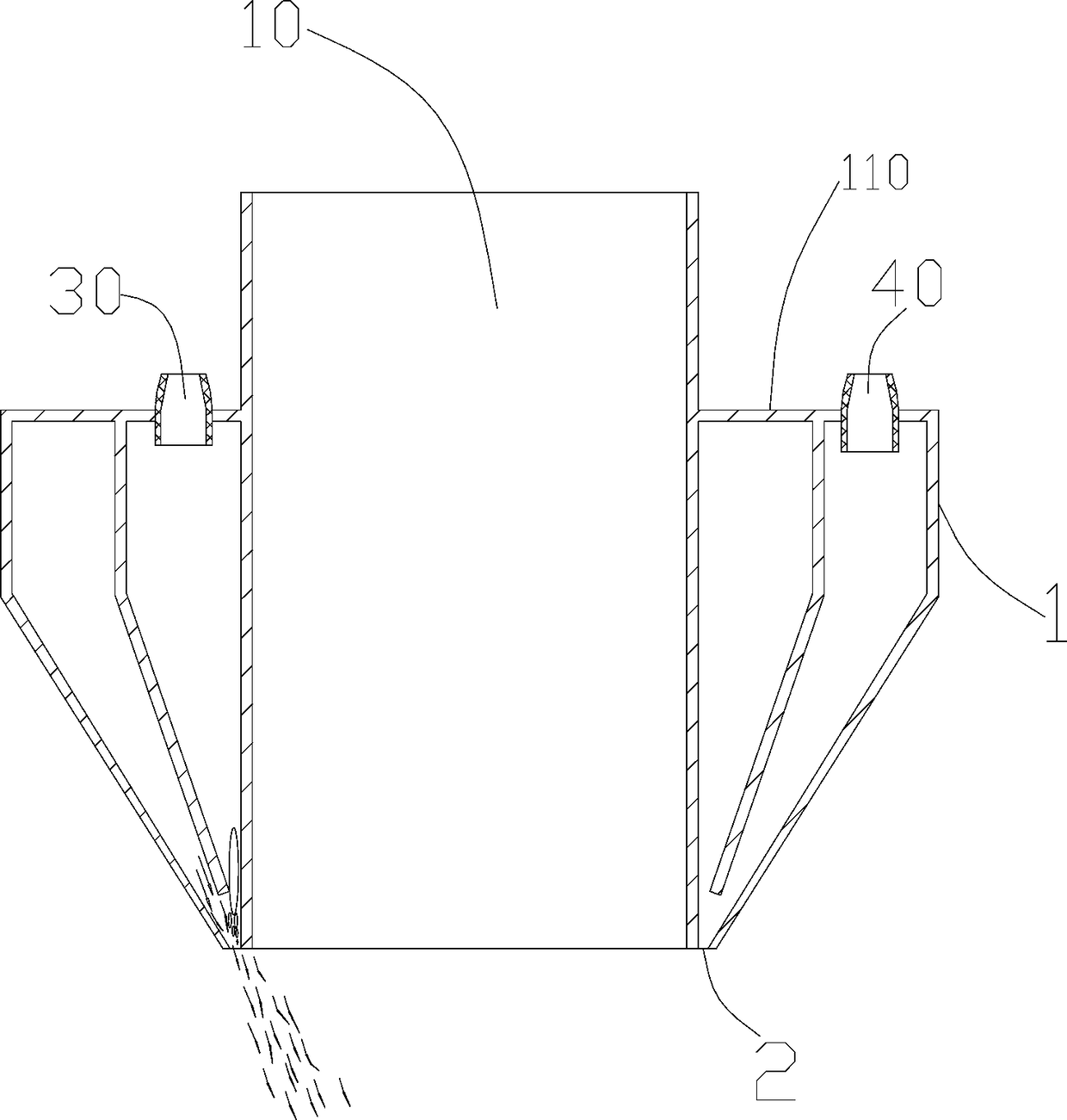

[0015] Embodiment 1: see Figure 1 to Figure 3 Shown is a specific embodiment of an EDM fluid atomizing nozzle of the present invention. An EDM fluid atomization nozzle, comprising a nozzle body 1, the nozzle body 1 includes a hollow tube 10 for installing an electrode 7, the upper end of the hollow tube 10 exceeds the nozzle body 1, the EDM clamp 6 and the nozzle body 1 are connected by inlays, the inner surface of the hollow tube 10 is a transition fit with the outer surface of the EDM fixture 6, the electrode 7 is fixed on the front end of the EDM fixture 6, and the nozzle body 10 has a sealed upper end cover 11 And the lower end of the opening, the hollow tube 10 runs through the nozzle body 1 and extends to the opening 2 provided at the lower end, an annular partition 12 is arranged in the nozzle body 1, and the nozzle body 1 is divided into a liquid cavity chamber 3 and gas chamber 4, the upper end cover 11 is respectively provided with a liquid inlet 30 and an air inle...

Embodiment 2

[0022] Embodiment 2: The gaps between the first annular seam and the second annular seam are both 2 mm, and other technical solutions are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com