Method and system for carrying out oil and dust removal on wastewater by mechanical demulsification

A technology for mechanical demulsification and wastewater treatment, which is applied in chemical instruments and methods, mechanical oscillation water/sewage treatment, multi-stage water treatment, etc. To achieve the effect of favorable comprehensive application, strong filtration effect and dirt holding capacity, and shortened residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

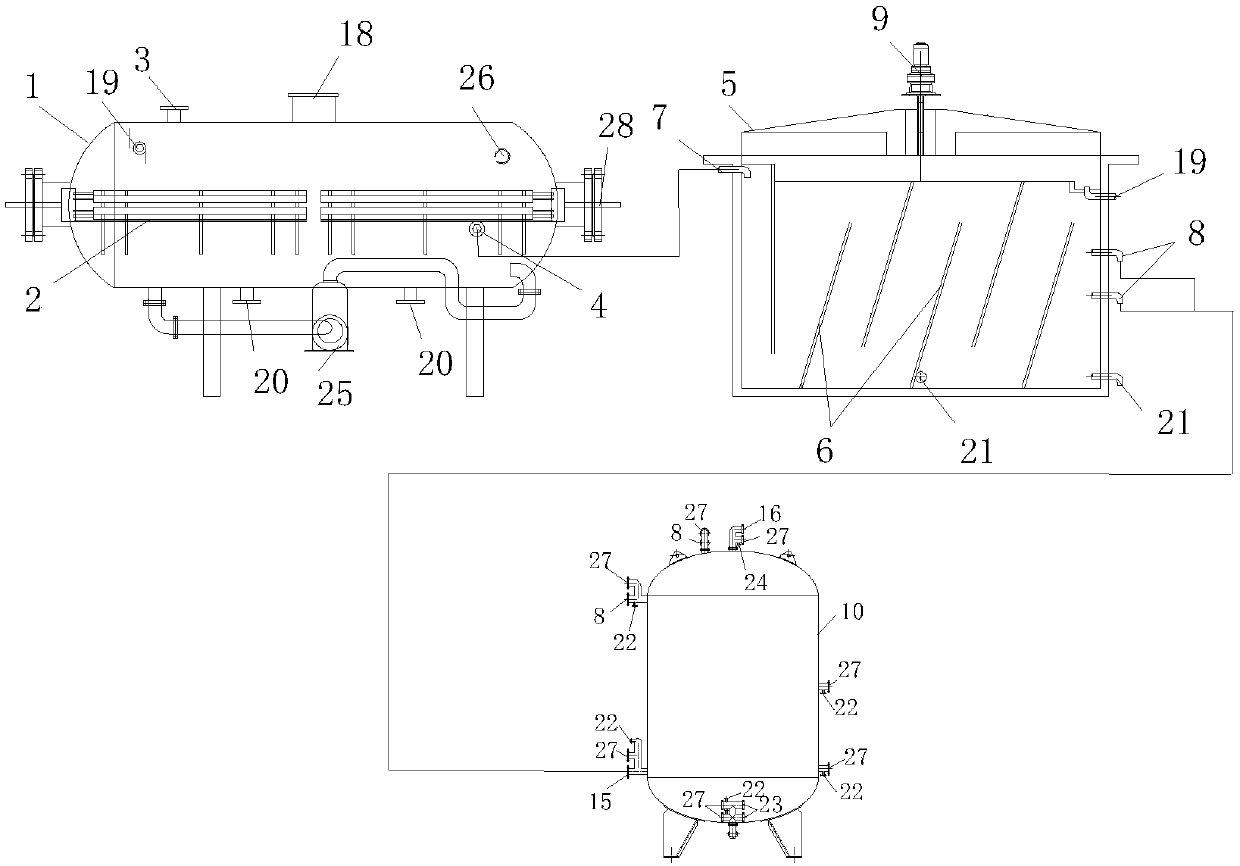

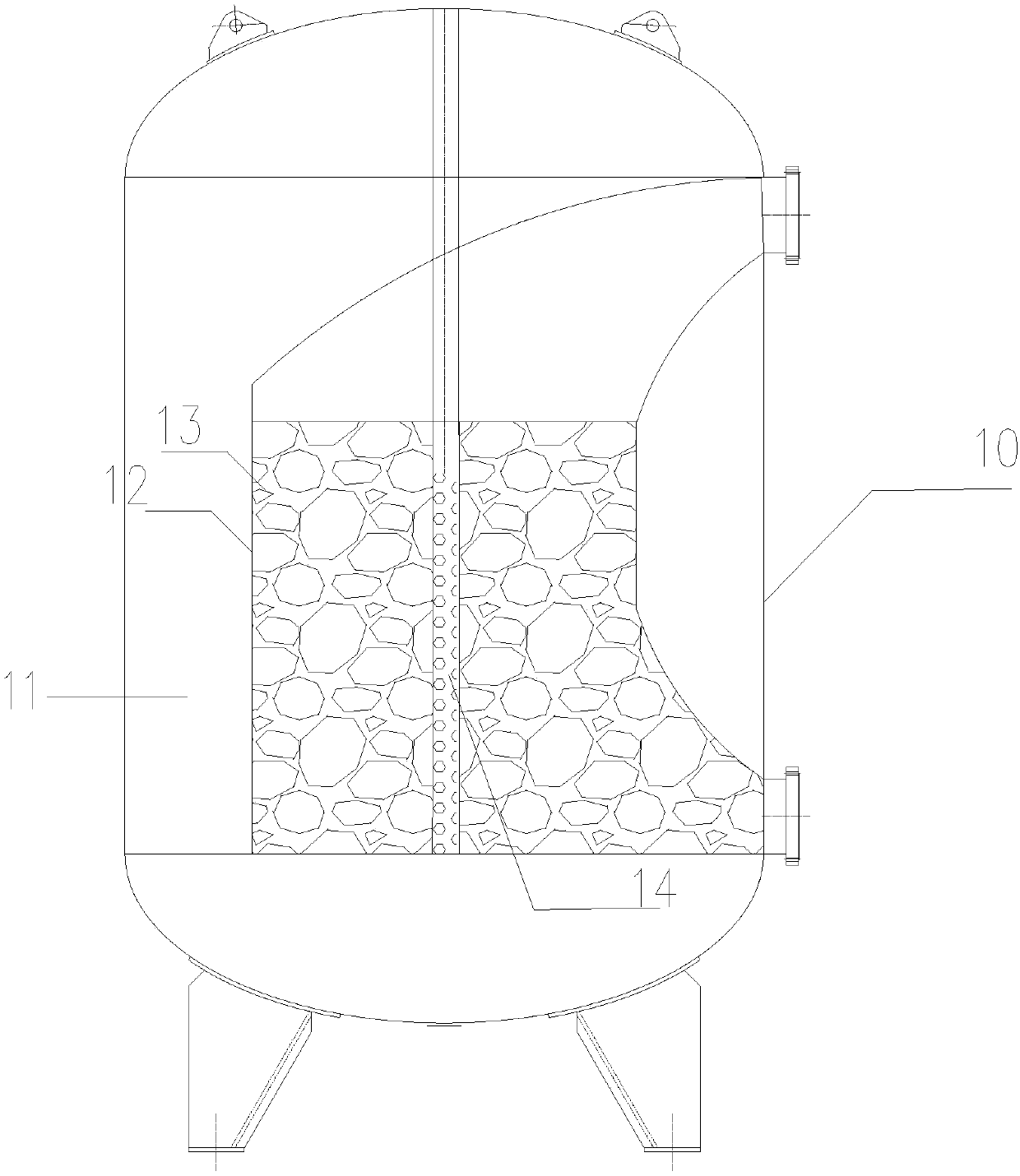

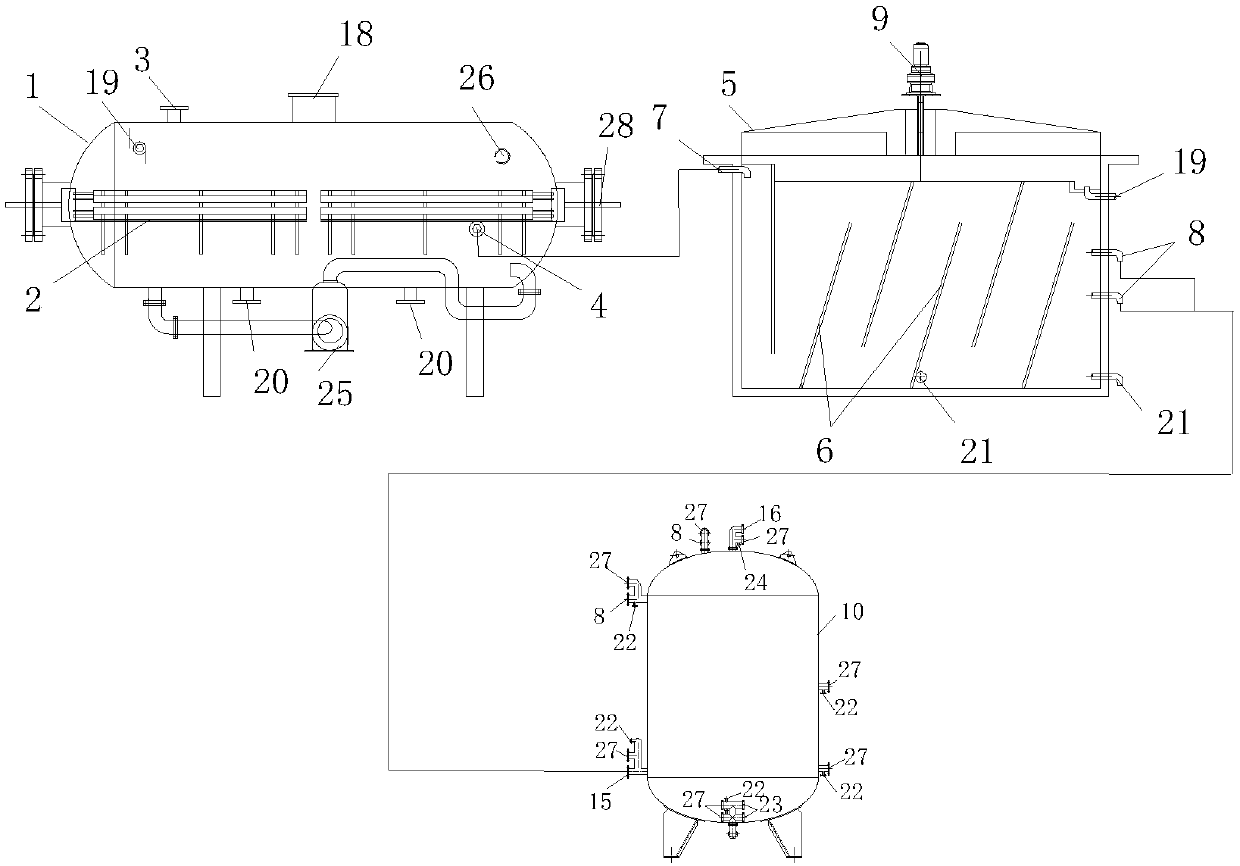

[0043] Example: see Figure 1 to Figure 2 , the present embodiment provides a method for mechanical demulsification, oil removal and dust removal of waste water, which comprises the following steps:

[0044] (1) Mechanical demulsification:

[0045] (1.1) A mechanical demulsification device is provided, which includes a tank body 1, a mechanical demulsification mechanism 2 is provided in the tank body 1, a mechanical demulsification water inlet valve 3 is provided on the top of the tank body 1, and a mechanical demulsification water inlet valve 3 is provided on the side of the tank body 1 There is a mechanical demulsification outlet valve 4;

[0046] (1.2) The waste water enters the tank body 1 through the mechanical demulsification inlet valve 3, and the mechanical demulsification mechanism 2 generates mechanical vibrations to condense the water particles. At the same time, the mechanical demulsification mechanism emits ultrasonic waves. When the ultrasonic waves pass through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com