Sintering desulfurization ash treatment system and method

A technology of sintering desulfurization ash and treatment system, which is applied in the direction of cement production, etc., can solve the problems of practical application limitations, unfavorable two sensitive indicators of activity index and chloride ion content, etc., and achieve uniform distribution, resource saving, and reduction of environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be more fully understood through the following specific embodiments that should be read together with the accompanying drawings. Detailed embodiments of the present invention are disclosed herein; however, it should be understood that the disclosed embodiments are only exemplary of the present invention, and the present invention can be embodied in various forms. Therefore, the specific functional details disclosed herein should not be construed as restrictive, but only as the basis of the claims and construed as teaching those skilled in the art to differ in any appropriate detailed embodiment. The method adopts the representative basis of the present invention.

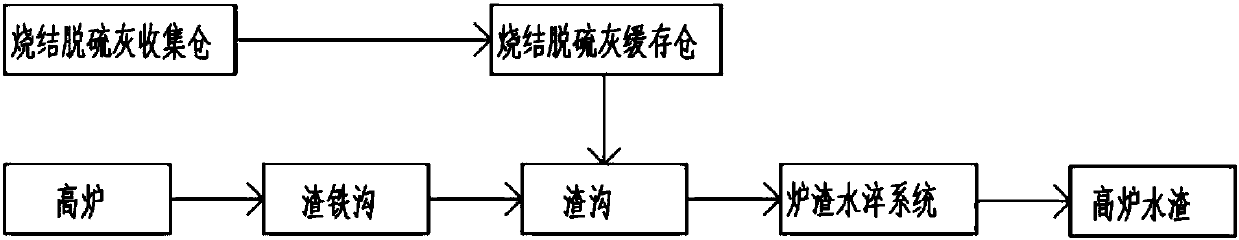

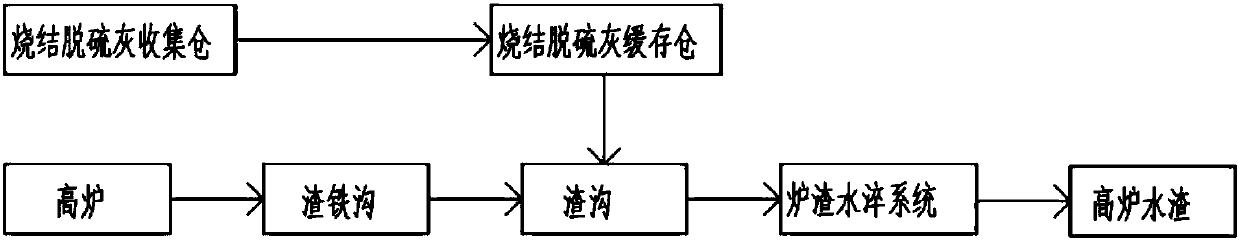

[0027] Combine figure 1 As shown, the sintering desulfurization ash treatment system includes a semi-dry sintering desulfurization device, a sintering deashing collection bin, an ironmaking blast furnace, a slag water quenching system, and a grinding device. The ironmaking blast furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com