Cement-based self-leveling mortar and preparation method thereof

A self-leveling mortar and cement-based technology is applied in the field of preparation of cement-based self-leveling mortar, which can solve the problems of unreasonable setting time, insufficient water reduction rate, rapid loss of fluidity, etc. Good self-compactness and low bubble rate

Inactive Publication Date: 2017-05-24

SHANGHAI DONGDA CHEM

View PDF4 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The technical problem to be solved by the present invention is to overcome the insufficient water-reducing rate of cement-based self-leveling mortar in the prior art, excessive shrinkage, rapid loss of fluidity, low fluidity, unreasonable setting time, high cost, and increased cost. A kind of cement-based self-leveling mortar and its preparation method are provided

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

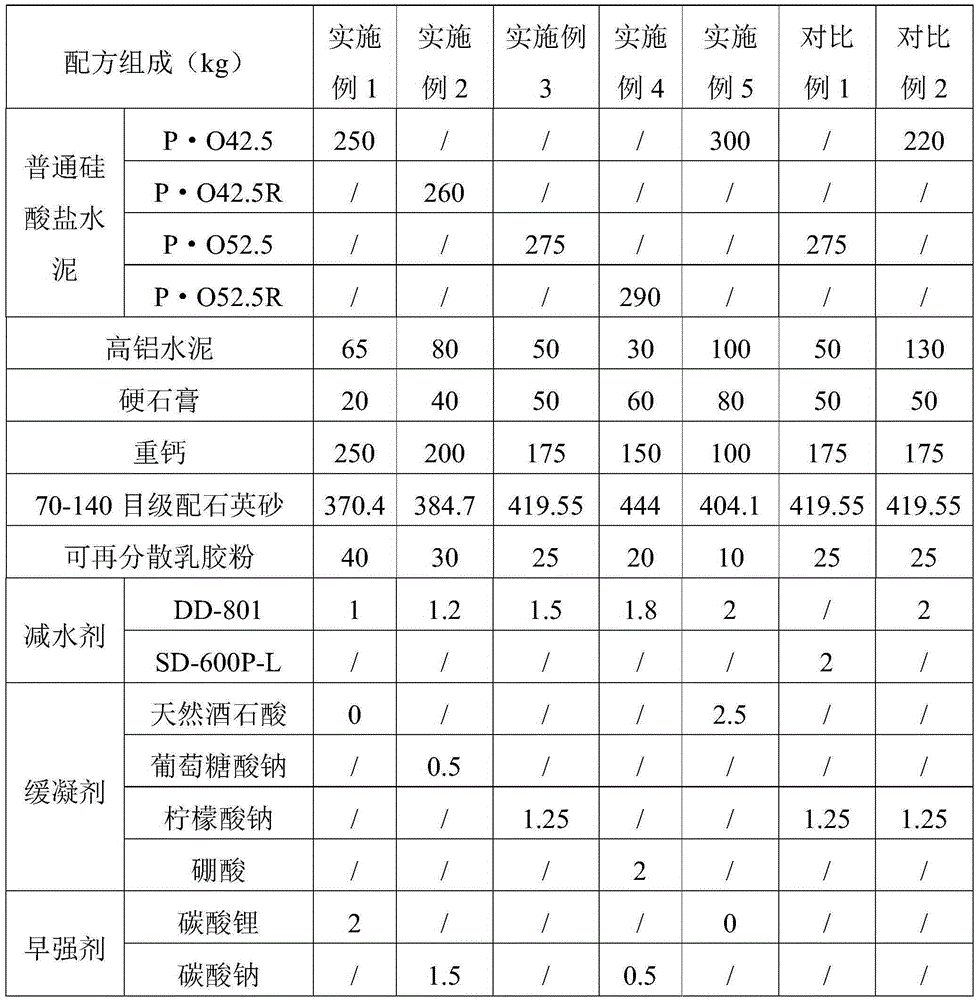

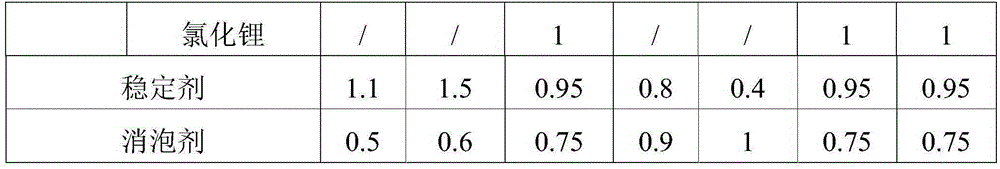

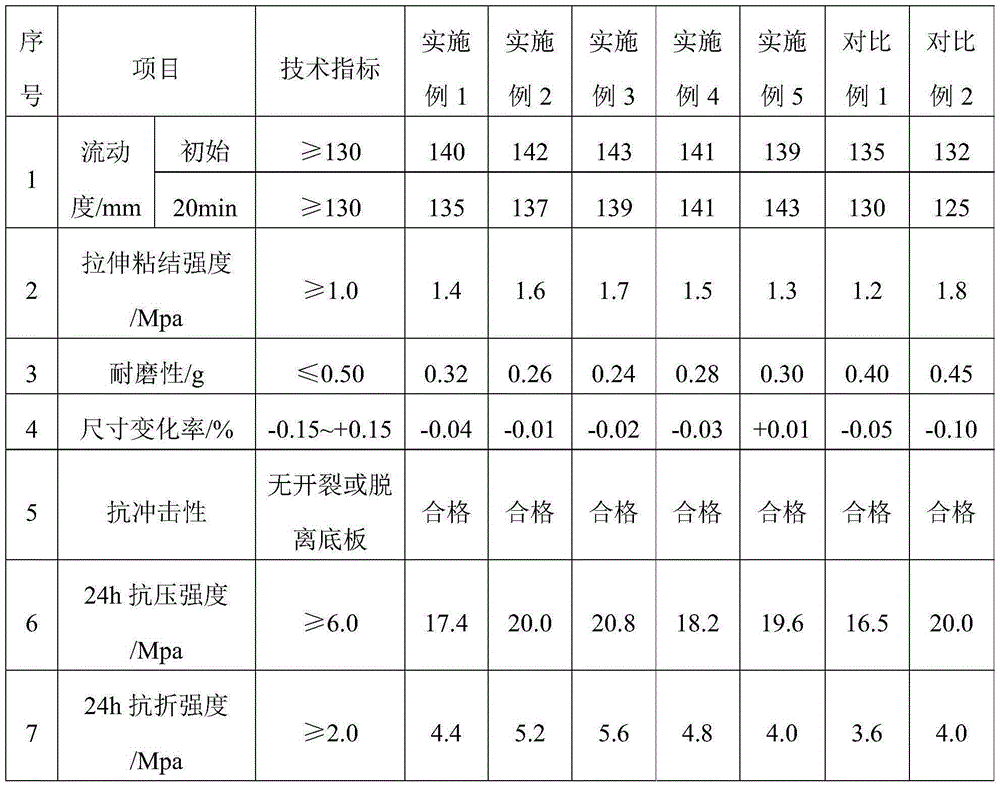

Embodiment 1~5

[0057] Table 1

[0058]

[0059]

[0060] The cement-based self-leveling mortar described in the present invention can be obtained by selecting the above-mentioned raw material weighing, batching, stirring and mixing, and quality inspection. (" / " in Table 1 indicates that the item is not added, that is, the amount added is 0)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses cement-based self-leveling mortar and a preparation method thereof. The cement-based self-leveling mortar comprises the following raw materials: a powdery polycarboxylate water reducing agent, silicate cement, high-alumina cement, anhydrite, triple superphosphate, redispersible latex powder, a stabilizing agent, a defoaming agent, a retarder, a hardening accelerator and graduated quartz sand, wherein the powdery polycarboxylate water reducing agent has the brand of DD-801. The initial fluidity and the 20min fluidity of the cement-based self-leveling mortar are higher than 130mm, the 24h breaking strength is higher than 2MPa, the 24h compressive strength is higher than 6MPa, and all indexes meet requirements of national standards; in addition, compared with the conventional mortar, the cement-based self-leveling mortar provided by the invention has the advantages of low water-cement ratio, good self-leveling performance and self-compactness, high fluidity, high fluidity retentivity, low bubble rate, high strength and higher leveling performance and early strength.

Description

technical field [0001] The invention specifically relates to a cement-based self-leveling mortar and a preparation method thereof. Background technique [0002] Self-leveling mortar emerged in the 1970s and began to develop in my country in the late 1980s and early 1990s. Self-leveling mortar is a kind of inorganic cementitious material or organic cementitious material as the base material, mixed with a certain amount of aggregate and filler. , and then add an appropriate amount of functional admixture, it is a building material that can be used for ground leveling after mixing, or it can be used for ground leveling through auxiliary paving. It has the advantages of high fluidity, low shrinkage, high strength, good wear resistance, self-smoothing, fast drying and solidification, thin thickness, and convenient construction. It can effectively solve the quality problems caused by the plastering construction of traditional ground materials, such as slow construction speed, long...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/06C04B14/06C04B22/14

Inventor 罗琼高振伟王万林李亚杰杜辉董建国王振波

Owner SHANGHAI DONGDA CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com