A kind of sol-bonded blast furnace lining wet spray coating and its preparation method

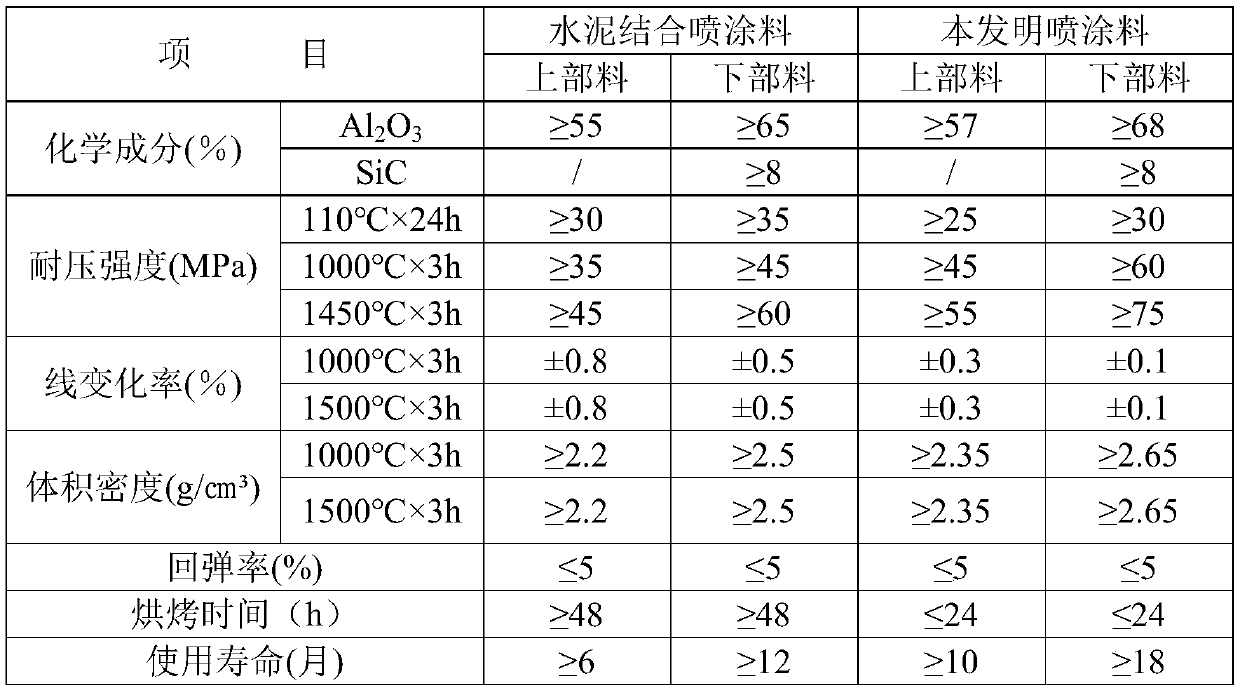

A wet spray coating and sol technology, used in the field of refractory materials, can solve the problems of poor high temperature durability, poor corrosion resistance, low high temperature strength, etc., and achieve improved erosion resistance, erosion resistance and compactness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

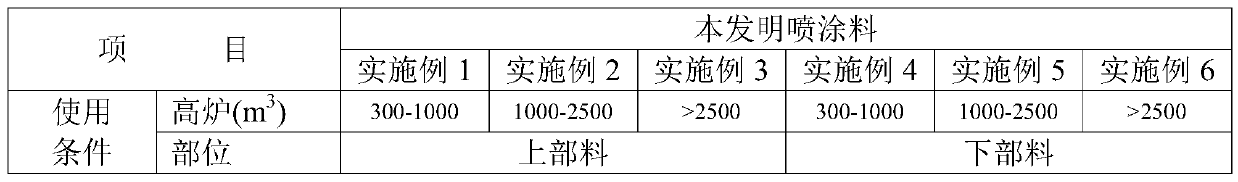

[0043] Embodiments of the present invention are described below. Those skilled in the art would recognize that the described embodiments can be modified in various ways or combinations thereof without departing from the spirit and scope of the invention.

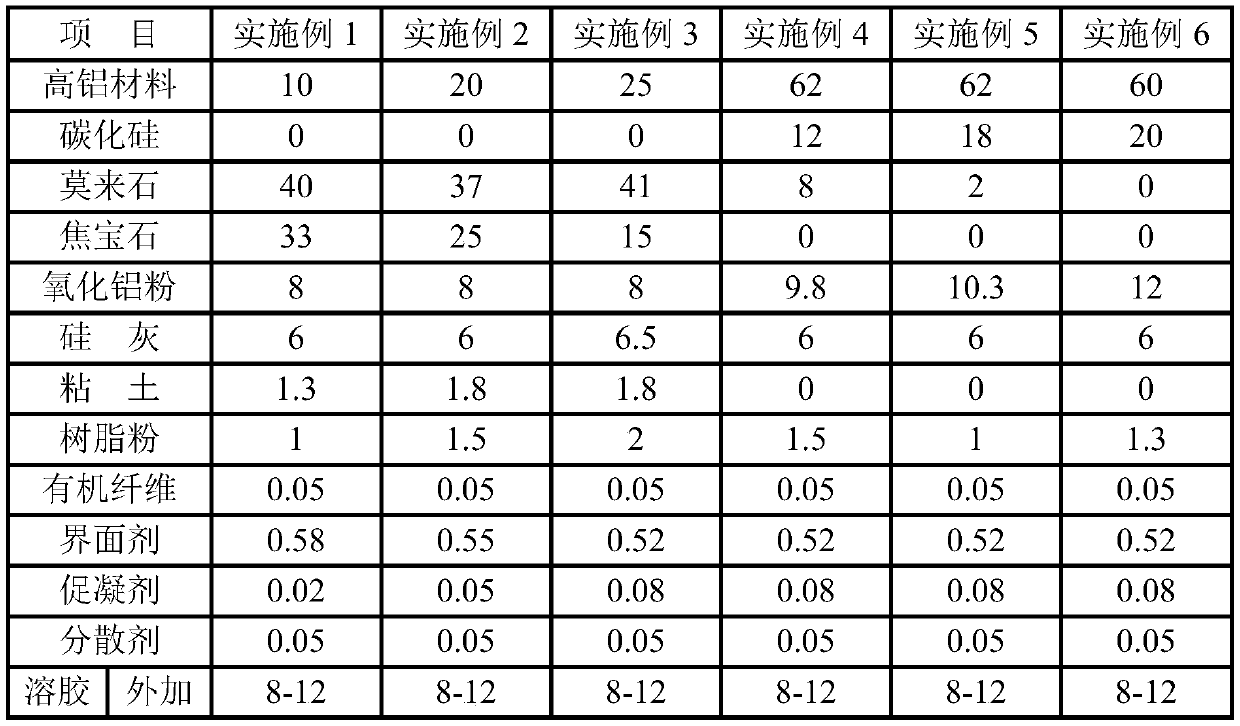

[0044] Wet method spray coating of the present invention, by mass percentage, its raw material composition is as follows:

[0045] Silicon carbide: less than or equal to 30 parts by weight,

[0046] High aluminum material: less than or equal to 80 parts by weight,

[0047] Mullite: less than or equal to 60 parts by weight,

[0048] Burnt gem: less than or equal to 60 parts by weight,

[0049] Aluminum oxide powder: 3-20 parts by weight,

[0050] Silica fume: 3-20 parts by weight,

[0051] Clay: less than or equal to 5 parts by weight,

[0052] Resin powder: 0.5-5 parts by weight,

[0053] Organic fiber: 0.02-1 parts by weight,

[0054] Interface agent: less than or equal to 1 part by weight,

[0055] Coagulant: 0.01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com