Method for preparing molybdenum disulfide/copper/cobalt catalyzing hydrogen evolution layer on surface of foam iron

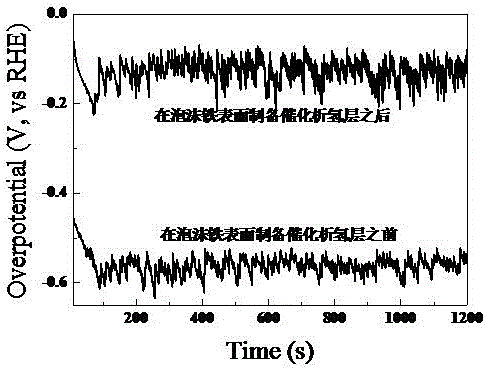

A technology of molybdenum disulfide and iron foam, which is applied in the field of preparation of catalytic hydrogen evolution materials, can solve the problem of low hydrogen evolution activity and achieve the effects of large surface area, excellent catalytic activity and increased conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: a kind of method of preparing molybdenum disulfide / copper / cobalt catalytic hydrogen evolution layer on the foam iron surface of the present embodiment is carried out according to the following steps:

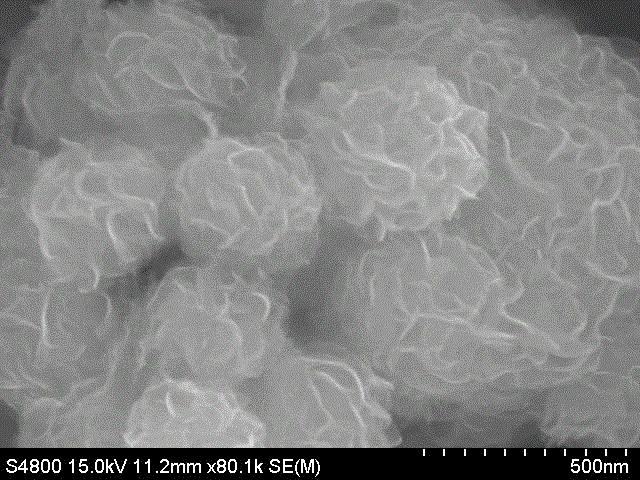

[0018] (1) Preparation of flower-like molybdenum disulfide colloidal liquid: a. Weigh 0.5~5.0 g of anionic surfactant, add it into 1000 mL deionized water, stir at room temperature for 5~15 min, then add 0.2~1.2 g flower-shaped molybdenum disulfide; b. After stirring at 60 °C for 2 h, use an ultrasonic cell pulverizer for 2 h; c. repeat step b 1 to 6 times to complete the preparation of flower-shaped molybdenum disulfide colloid;

[0019] (2) Preparation of cationic polyacrylamide gel: d. Dissolve cationic polyacrylamide with a concentration of 3.0-6.0 g / L in deionized water, stir at 40-60 °C for 3-5 h to prepare Cationic polyacrylamide solution;

[0020] (3) Foam iron pre-treatment: e. Soak the foam iron in acetone for 1-5 minutes to remove surf...

specific Embodiment approach 2

[0025] Specific embodiment two: what this embodiment is different from specific embodiment one is that the anionic surfactant described in the a of step (1) is sodium lauryl sulfate, sodium lauryl sulfonate or dodecane One of the base alcohol polyoxyethylene ether sodium sulfates. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the molecular weight of the cationic polyacrylamide described in step (2) d is 18 million to 25 million. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com