Coating, preparation method and matte coated paper using the coating

A coating and coating component technology, applied in paper coating, pigment/opacifier addition, papermaking, etc., can solve problems such as unstable pigment production quality, high printing wear on paper pages, dot loss, etc., achieve excellent printing quality, improve Effects of drying performance and printability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

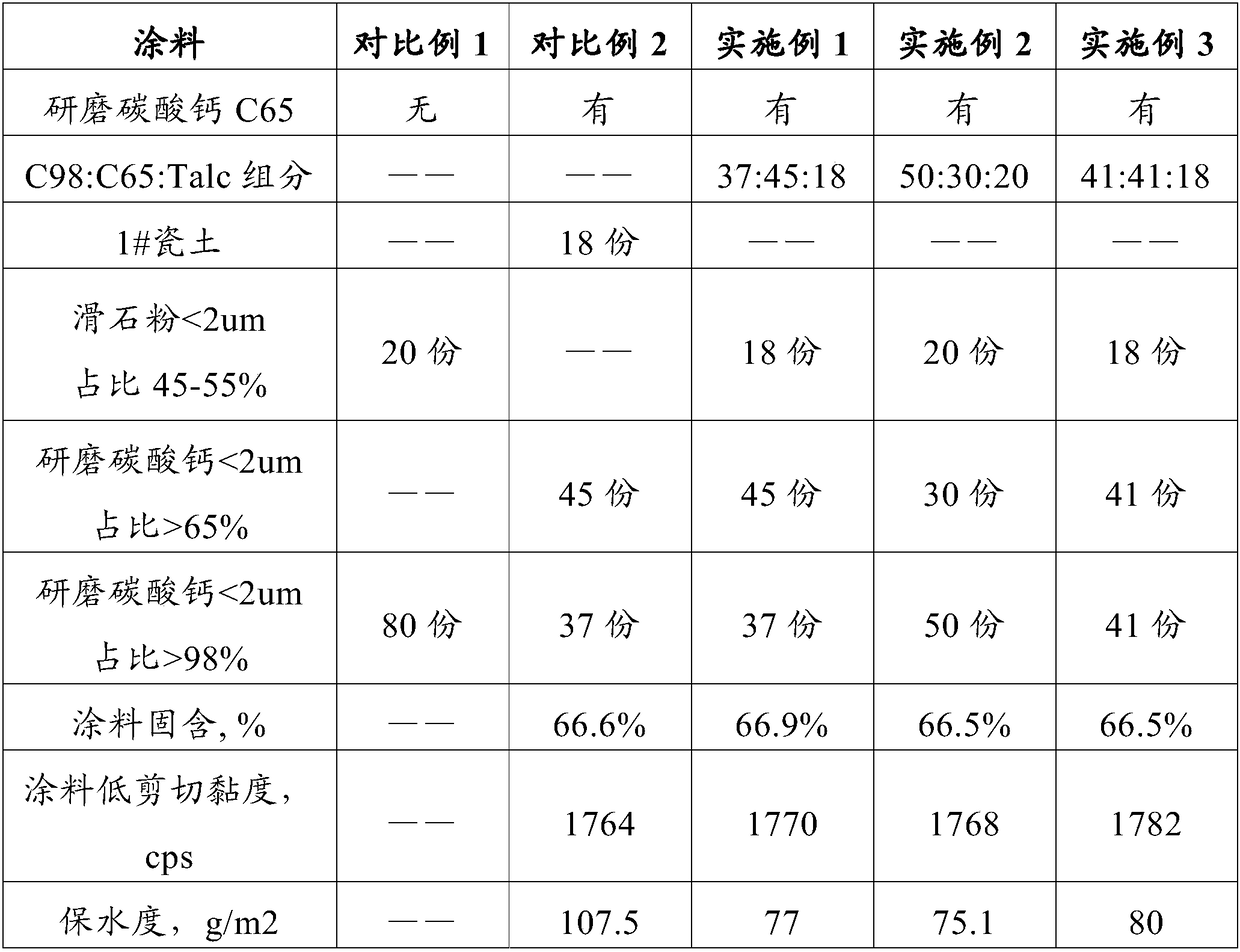

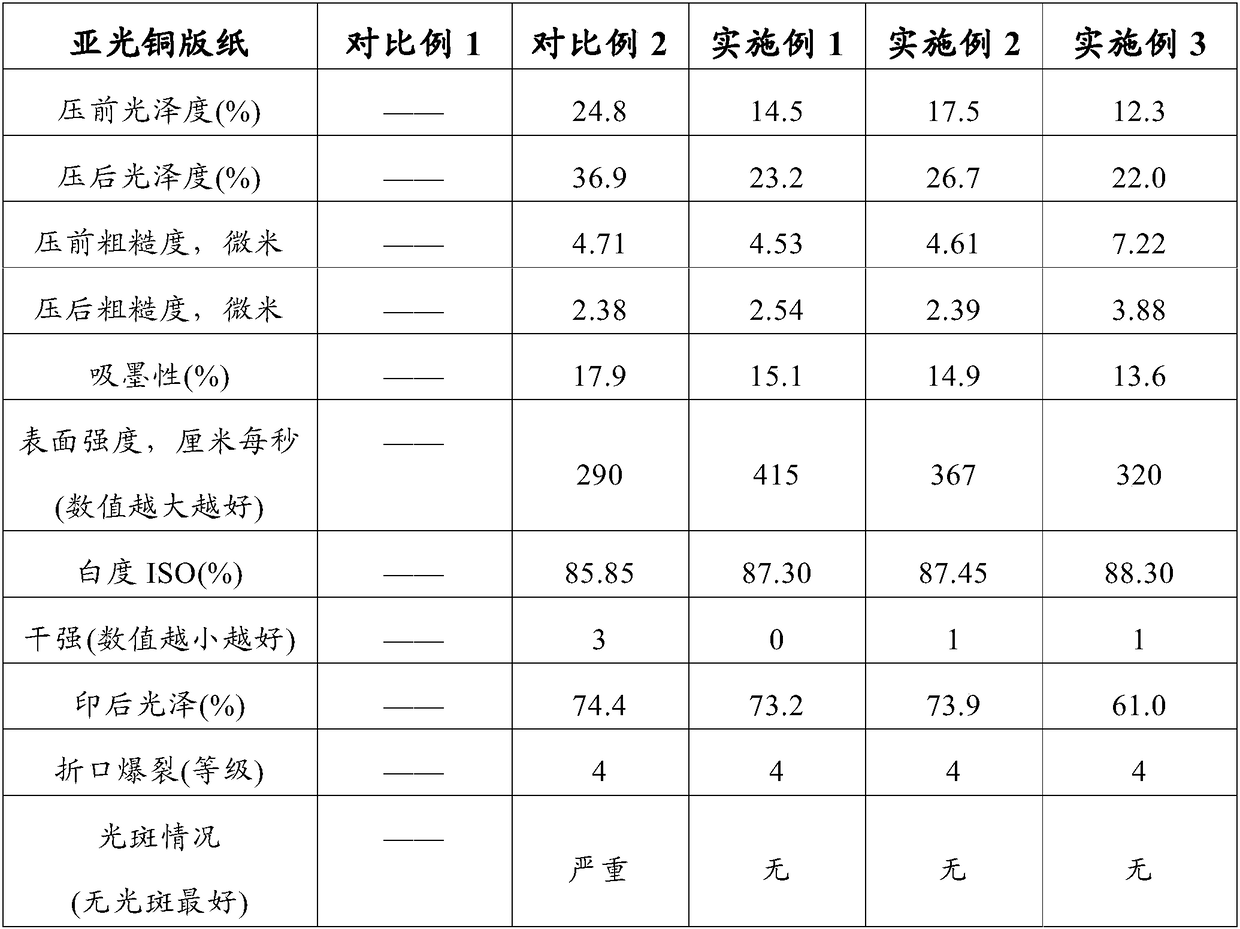

Embodiment 1

[0030] A paint comprising

[0031] 0.15 parts of dispersant,

[0032] Talc powder <2um accounts for 45-55% 18 parts,

[0033] Grinding calcium carbonate 98% C98 grade 37 parts,

[0034] Grinding calcium carbonate <2um accounts for 60-65% C65 grade 45 parts,

[0035] 10.5 parts of adhesive, 0.05 parts of defoamer, 0.2 parts of lubricant,

[0036] Sodium hydroxide 0.1 part, thickener 1.03 part.

[0037] The preparation method of above-mentioned coating, comprises the following steps:

[0038] (1) Calculated in parts by weight, ground calcium carbonate C98: ground calcium carbonate C65: talcum powder is 37:45:18. First prepare ground calcium carbonate C65 and talcum powder, add 174g of water into a 1500ml plastic beaker, then add 11.9g of dispersant with a solid content of 50%, stir with a low-speed mixer at 200rpm, and then add 1185g of solid content while stirring 75% ground calcium carbonate C65, stirred for 2 minutes, and finally slowly added 395g of talc powder with a...

Embodiment 2

[0041] A paint comprising

[0042] 0.15 parts of dispersant,

[0043] Talc powder <2um accounts for 45-55% 20 parts,

[0044] Grinding calcium carbonate 98% C98 grade 50 parts,

[0045] Ground calcium carbonate <2um accounts for 60-65% C65 grade 30 parts,

[0046] 10.5 parts of adhesive, 0.05 parts of defoamer, 0.2 parts of lubricant,

[0047] Sodium hydroxide 0.1 part, thickener 1.05 part.

[0048] The preparation method of above-mentioned coating, comprises the following steps:

[0049] (1) Calculated in parts by weight, ground calcium carbonate C98: ground calcium carbonate C65: talcum powder is 50:30:20. First prepare ground calcium carbonate C65 and talcum powder, add 180g of water into a 1500ml plastic beaker, then add 11.9g of dispersant with a solid content of 50%, stir with a low-speed mixer at 200rpm, and then add 790g of solid content while stirring 75% ground calcium carbonate C65, stirred for 2 minutes, finally slowly added 439g of talcum powder with a soli...

Embodiment 3

[0052] A paint comprising

[0053] 0.15 parts of dispersant,

[0054] Talc powder <2um accounts for 45-55% 18 parts,

[0055] Grinding calcium carbonate 98% C98 grade 41 parts,

[0056] Grinding calcium carbonate <2um accounts for 60-65% C65 grade 41 parts,

[0057] 10 parts of adhesive, 0.02 parts of defoamer, 0.2 parts of lubricant,

[0058] 0.05 part of sodium hydroxide, 1 part of thickener.

[0059] The preparation method of above-mentioned coating, comprises the following steps:

[0060] (1) Calculated in parts by weight, ground calcium carbonate C98: ground calcium carbonate C65: talcum powder is 41:41:18. First prepare ground calcium carbonate C65 and talcum powder, add 182g of water into a 1500ml plastic beaker, then add 11.9g of dispersant with a solid content of 50%, stir with a low-speed mixer at 200rpm, and then add 1100g of solid content while stirring 75% ground calcium carbonate C65, stirred for 2 minutes, and finally slowly added 400 g of talcum powder w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com