Well wall mud cake scraping tool and method for open hole well

An open-hole well and mud cake technology, which is applied in wellbore/well components, drilling equipment, earth-moving drilling, etc. to improve the bonding strength and flushing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

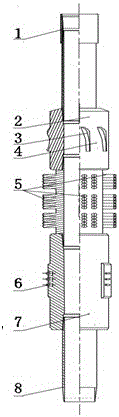

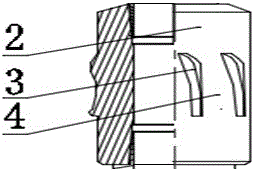

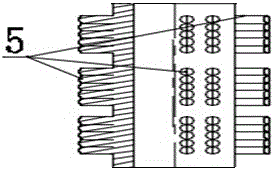

[0029] Embodiment 1, a wellbore mud cake scraping tool for an open hole mentioned in the present invention, including an upper joint 1, a rigid centralizer sub-joint 2, a mud cake scraping steel wire sub-joint 5, a ball centralizer sub-joint 7, The lower joint 8, the upper joint 1 and the lower joint 8 are connected to the pipe, the rigid centralizer sub-joint 2, the mud cake scraping steel wire sub-joint 5, and the ball centralizer sub-joint 7 are independent structures. The inner diameter is the same, and it is movably connected by a screw, and the contact surface is provided with a sealing rubber ring; the lower part of the rigid centralizer sub-joint 2 is connected to the mud cake scraping steel wire sub-joint 5, and the mud cake scraping steel wire sub-joint 5 is at the lower end Connect the ball centralizer short joint 7; the mud cake scraping steel wire short joint 5 is in interference fit with the wellbore, the steel wires outside the mud cake scraping steel wire short ...

Embodiment 2

[0036]Example 2, the second mud cake scraping tool for open hole wells mentioned in the present invention, including the upper joint 1, the rigid centralizer sub-joint 2, the mud cake scraping steel wire sub-joint 5, and the ball centralizer sub-joint 7 , the lower joint 8, the upper joint 1 and the lower joint 8 are connected to the pipe, the rigid centralizer sub-joint 2, the mud cake scraping steel wire sub-joint 5, and the ball centralizer sub-joint 7 are independent structures respectively, and the internal diameter and sleeve The inner diameter of the pipe is the same, and it is movably connected by a screw. The lower part of the ball centralizer sub-joint 7 is connected to the mud cake scraping steel wire sub-joint 5, and the lower end of the mud cake scraping steel wire sub-joint 5 is connected to the rigid centralizer sub-joint 2; The mudcake scraping steel wire nipple 5 is interference fit with the borehole, the steel wires outside the mudcake scraping steel wire nipp...

Embodiment 3

[0039] Example 3, the third mud cake scraping tool for open hole wells mentioned in the present invention, including the upper joint 1, the rigid centralizer sub-joint 2, the mud cake scraping steel wire sub-joint 5, and the ball centralizer sub-joint 7 , the lower joint 8, the upper joint 1 and the lower joint 8 are connected to the pipe, the rigid centralizer sub-joint 2, the mud cake scraping steel wire sub-joint 5, and the ball centralizer sub-joint 7 are independent structures respectively, and the internal diameter and sleeve The pipes have the same inner diameter and are movably connected by threads. The mud cake scraping steel wire sub-joint 5 is connected to the rigid centralizer sub-joint 2, and the lower end of the rigid centralizer sub-joint 2 is connected to the ball centralizer sub-joint 7; The cake scraping steel wire nipple 5 is in interference fit with the borehole, the steel wires outside the mud cake scraping steel wire nipple (5) are arranged in a straight l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com