Single-plunger double-displacement reciprocating rotation hydraulic drive

A hydraulic drive and reciprocating rotation technology, applied in the field of hydraulic pumps, can solve the problems of high material and processing accuracy, high oil cleanliness, inconvenient plug-in installation, etc., achieve low structural accuracy requirements, light weight, improve efficiency and The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

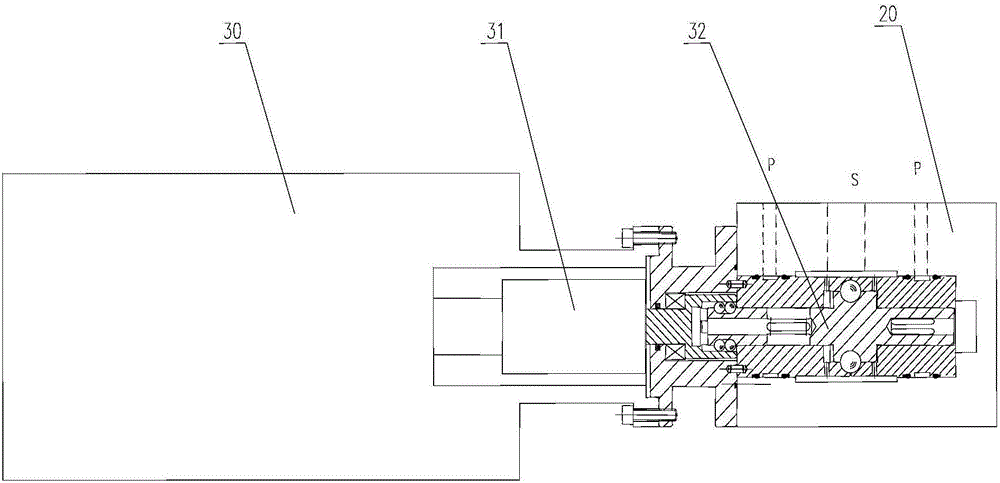

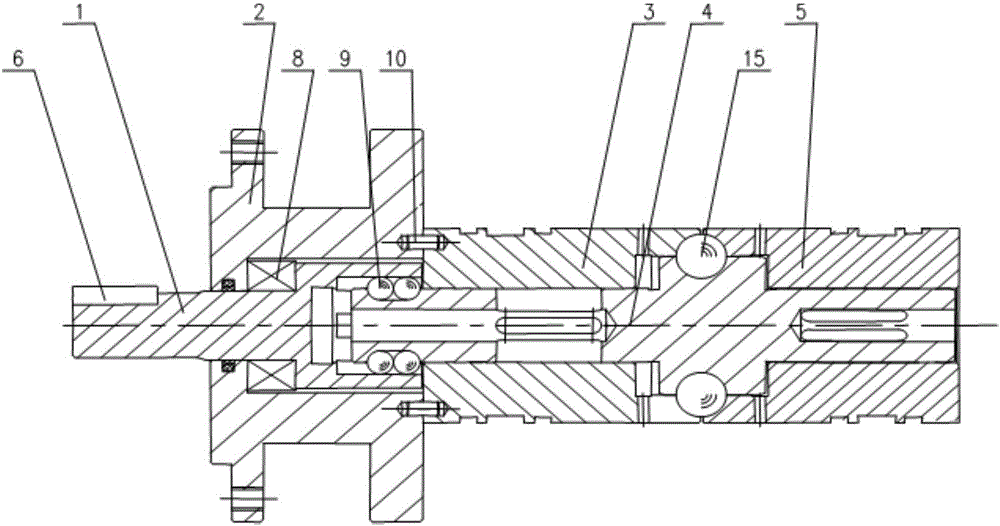

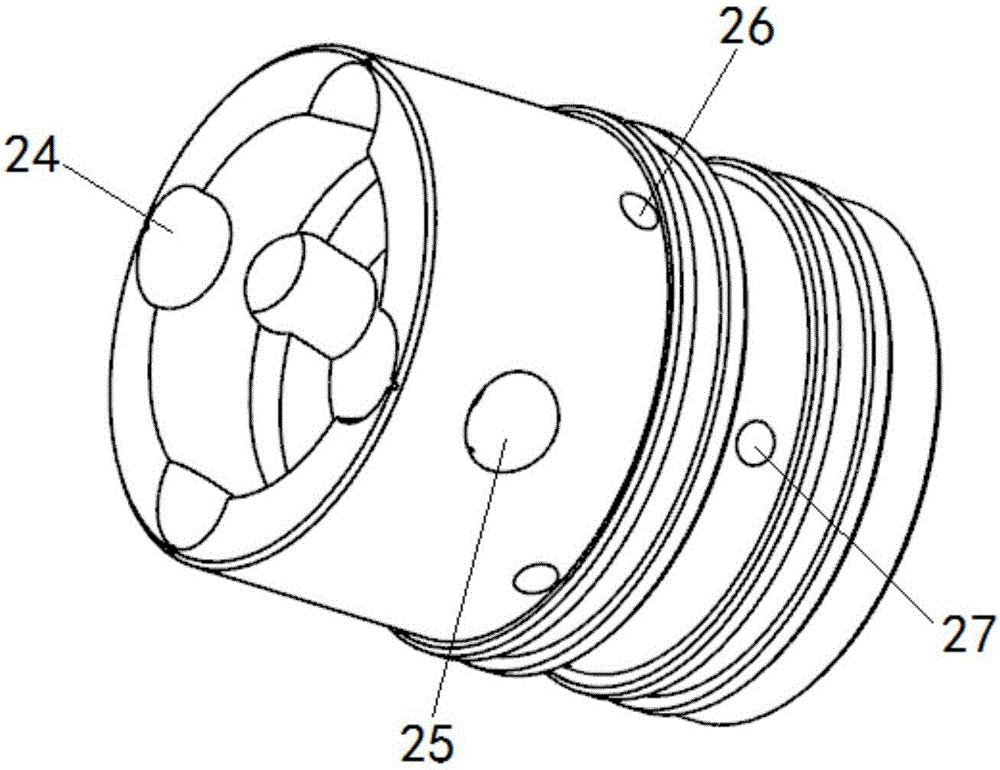

[0026] Such as Figure 1 to Figure 7 As shown, a single-plunger double-displacement reciprocating rotary hydraulic driver includes a motor 30, an input shaft 1, a front cover 2, a pump body 20, a pump sleeve, a pump core 4, a floating coupling, and high-precision steel balls 9 , Steel ball 15 etc.

[0027] The input shaft 1 is installed in the front end cover 2, and the pump sleeve is installed on the end surface of the front end cover 2. The pump sleeve has an oil suction port S and two oil discharge ports P. The pump sleeve is equipped with a pump core 4. One end of the input shaft 1 is connected to the motor, and the other end is The pump core 4 is connected by a floating coupling, and the motor 30 drives the pump core 4 to rotate in the pump sleeve through the input shaft 1. The pump sleeve and the pump core 4 pass through the semicircular groove 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com