Gear-rack-crankshaft linkage engine conversion mechanism

A conversion mechanism and engine technology, applied in the directions of machines/engines, belts/chains/gears, transmissions, etc., can solve the problems of reducing the work efficiency of the piston, accelerating the lateral wear of the cylinder wall, and complex stress state, and achieve power transmission. Reasonable effect of conversion with exercise mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] specific implementation plan

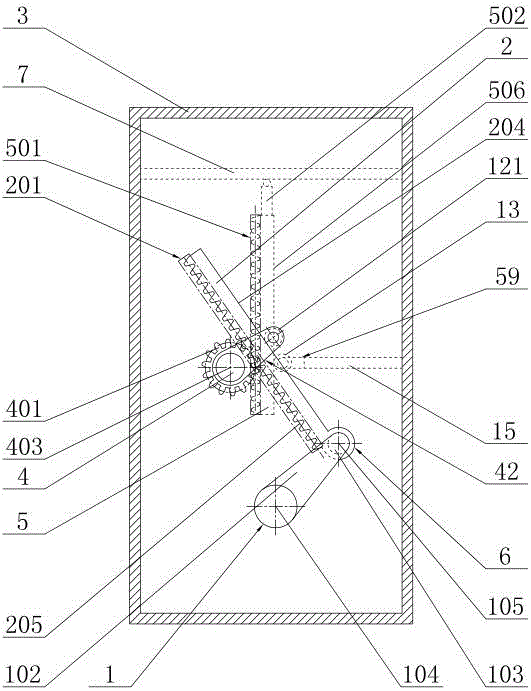

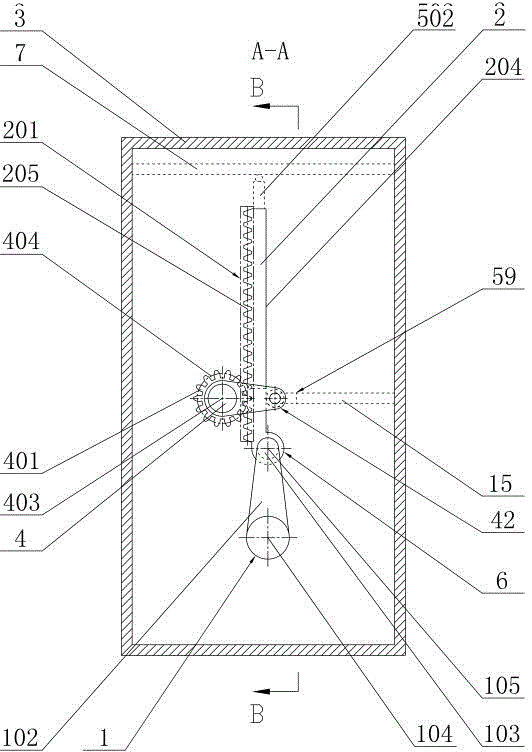

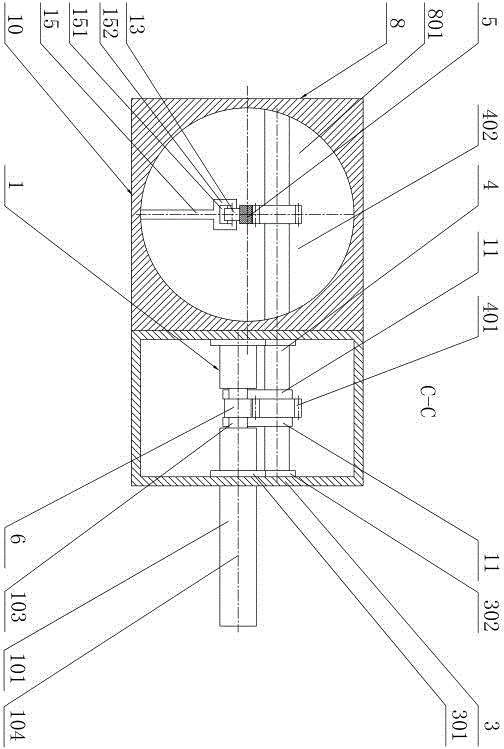

[0036] The specific implementation of a pinion-rack-crankshaft linkage engine conversion mechanism provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0037] Such as figure 1 , 2 , 3, and 4, the operating process of the first embodiment of the present invention is as follows: the main journal 101 of the crankshaft 1 is rotatably installed on the two side walls of the crankcase 3, and a rack joint 6 is arranged at one end of the main rack 2, The rack journal 103 at the end of the crank arm 102 is hinged with the main rack 2 by means of the rack joint 6. The transmission shaft 4 is installed in the bearings 301 on the two side walls of the crankcase 3. 201 meshes with the main gear 401 arranged on the cylindrical surface of the transmission shaft 4, and a limit mechanism 42 is arranged between the main rack 2 and the main gear 401; Cylinder block 9, power transmission shaft 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com