Anti-scratch diffusion film and backlight module

An anti-scratch and diffusion film technology, applied in optics, optical components, nonlinear optics, etc., can solve problems such as poor scratch resistance, and achieve the effect of improving quality, no fire safety hazards, and reducing human hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

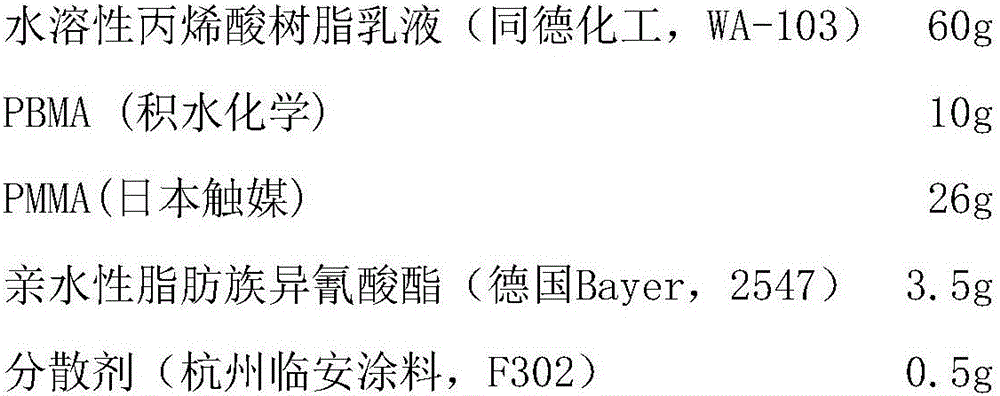

[0033] Preparation of main diffusion layer coating solution:

[0034]

[0035] Preparation of back coating solution:

[0036]

[0037]According to the composition formula of the main diffusion layer in Example 1 above, prepare the raw materials for the coating liquid: add the water-soluble resin emulsion and diffusion particles in the formula to the disperser for 30 to 40 minutes, and then add the resin crosslinking agent and dispersant for 10 to 15 minutes. Make the main diffusion layer coating solution; apply the uniformly dispersed main diffusion layer coating solution on the upper surface of the transparent substrate layer made of polyethylene terephthalate film, then carry out drying treatment, and finally carry out Aging treatment, aging for 12 hours to 24 hours to form the main diffusion layer of the diffusion film; the thickness of the main diffusion layer is 1 / 2 to 3 / 4 of the particle diameter of the largest PBMA particle.

[0038] According to the composition ...

Embodiment 2

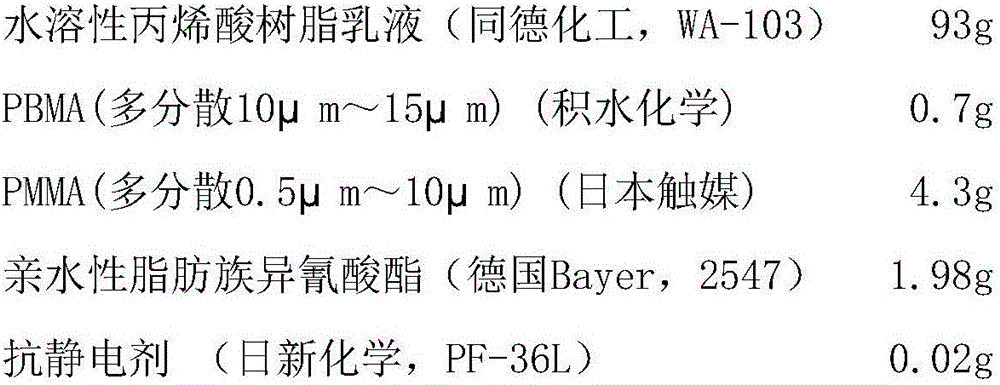

[0040] Preparation of main diffusion layer coating solution:

[0041]

[0042] Preparation of back coating solution:

[0043]

[0044] According to the composition formula of the main diffusion layer in the above-mentioned embodiment 2, prepare the raw materials of the coating solution: add the water-soluble resin emulsion and diffusion particles in the formula to the disperser for 30 to 40 minutes, and then add the resin crosslinking agent and dispersant for 10 to 15 minutes. Make the main diffusion layer coating solution; apply the uniformly dispersed main diffusion layer coating solution on the upper surface of the transparent substrate layer made of polymethyl methacrylate film, then carry out drying treatment, and finally carry out aging treatment, Aging for 12 hours to 24 hours forms the main diffusion layer of the diffusion film; the thickness of the main diffusion layer is 1 / 2 to 3 / 4 of the particle diameter of the largest PBMA particle.

[0045] According to th...

Embodiment 3

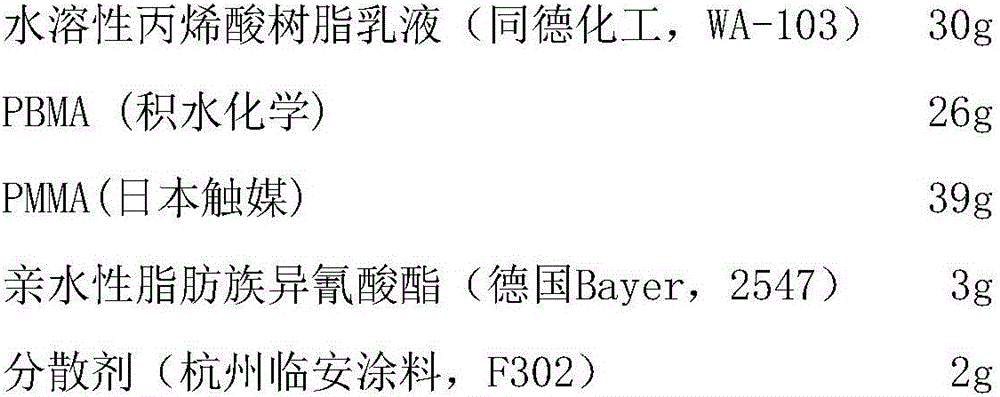

[0047] Preparation of main diffusion layer coating solution:

[0048]

[0049]

[0050] Preparation of back coating solution:

[0051]

[0052] According to the composition formula of the main diffusion layer in the above-mentioned embodiment 3, prepare the raw materials of the coating solution: add the water-soluble resin emulsion and diffusion particles in the formula to the disperser for 30 to 40 minutes, and then add the resin crosslinking agent and dispersant for 10 to 15 minutes. Make the main diffusion layer coating solution; apply the uniformly dispersed main diffusion layer coating solution on the upper surface of the transparent substrate layer made of polycarbonate film, then carry out drying treatment, and finally carry out aging treatment, aging for 12 hours After 24 hours, the main diffusion layer of the diffusion film is formed; the thickness of the main diffusion layer is 1 / 2 to 3 / 4 of the particle diameter of the largest PBMA particle.

[0053] Accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com