Industrial prawn culture system based on gas stripping circulation and industrial prawn culture method based on gas stripping circulation

An aquaculture system and technology for prawns, which are applied in the fields of climate change adaptation, fish farming, and application, can solve the problems of reduced efficiency of biological filtration, difficulty in utilizing upper water bodies, and inapplicability for cultivating prawns. Efficiency, the effect of reducing the energy consumption of water circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

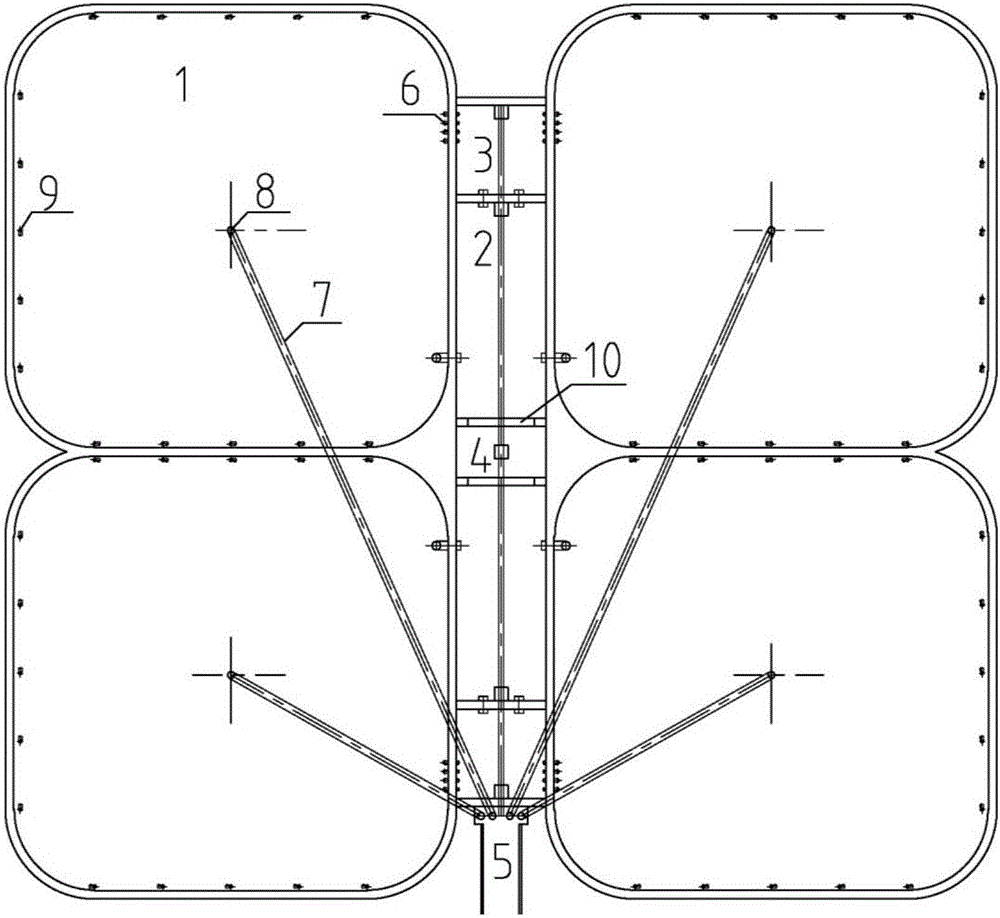

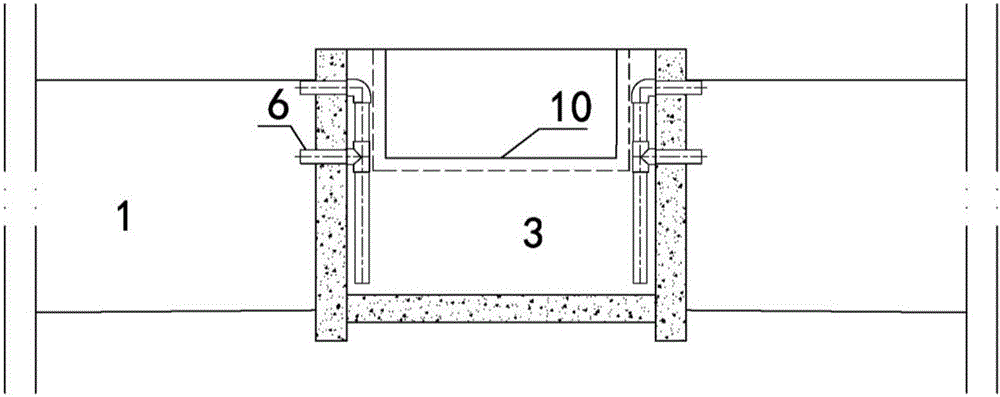

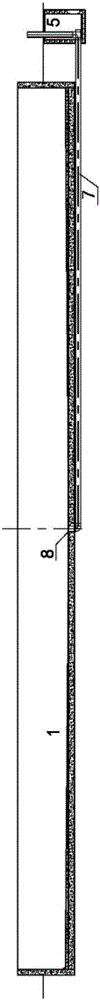

[0037] at 3200m 2There are 6 sets of industrialized shrimp farming systems in the industrialized shrimp farming workshop, and each set has 4 shrimp farming ponds. 1:50 down. The whole workshop is equipped with a 5.5kW Roots blower, and the air lift technology is used as the circulation power of the aquaculture water body, and at the same time, the water body is oxygenated.

[0038] There are 8 air stripping pipes in total, which are divided into upper and lower rows, and the water extraction capacity of each air stripping pipe is 10m 2 / h, the water circulation of each shrimp pond is 40m 2 / h. In the early stage of breeding, the water level was 110cm, and the lower exhaust lifting pipe was opened. In the later stage of breeding, the water level was 150cm, and the upper exhaust lifting pipe was opened.

[0039] The rotation of the water flow in the shrimp pond accelerates the accumulation of solid waste in the pond to the central sewage outlet, and the sewage is regularly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com