Pesticide spraying machine

A pesticide spraying and mechanical technology, which is applied in the device, application, animal husbandry and other directions of capturing or killing insects, can solve the problems of pesticide gasification, lack of resistance, and high cost, achieve mechanized management, and improve land output. the effect of reducing the degree of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

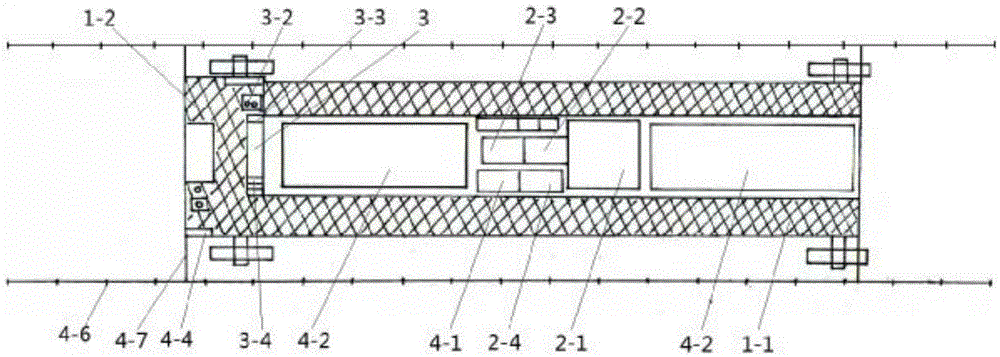

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

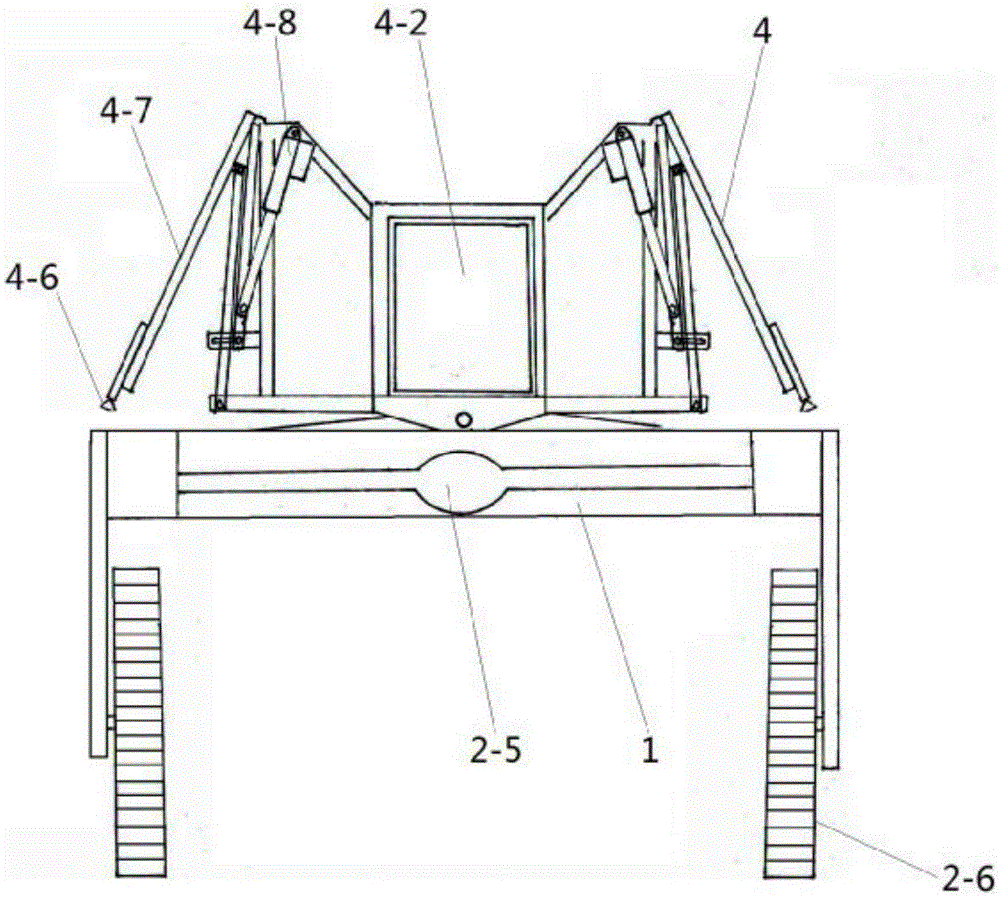

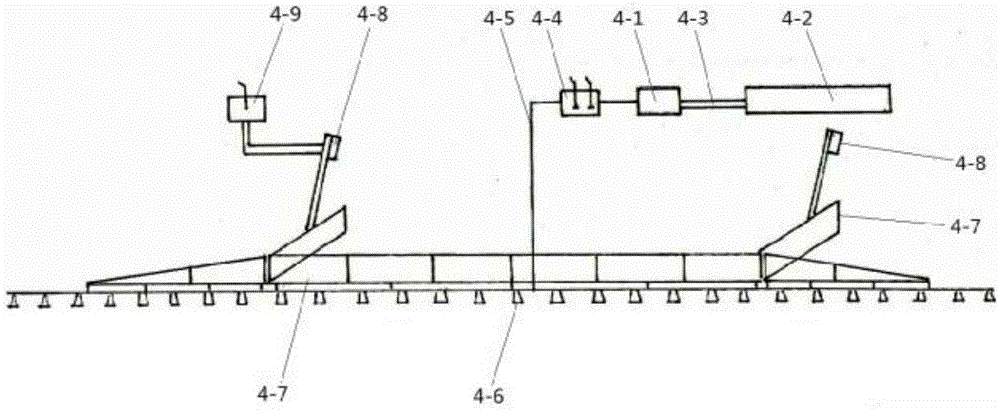

[0022] Such as Figure 1 to Figure 3 The pesticide spraying machine shown includes a chassis 1, a power part, a control part 3 and a spraying system 4. There are working aisles 1-1 on both sides of the chassis 1, and a driving console 1-2 on the front of the chassis 1.

[0023] The power part includes an engine assembly 2-1, and the engine assembly 2-1 is arranged at the center of the chassis 1 and connected to the fuel tank 2-4. The engine assembly 2-1 is connected to the central differential assembly 2-3 through the gearbox assembly 2-2, and the central differential assembly 2-3 passes through the transmission shaft and the drive axle differential assembly 2- 5 drives wheel 2-6 to rotate.

[0024] The control part 3 is located on the driving console 1-2, including a direction control lever 3-2, a clutch pedal 3-3, a brake pedal 3-4, an accelerator pedal a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap