Device for automatically drying and packaging fixed-length noodle

A noodle and automatic technology, applied in the direction of drying, drying machine, cutting noodles, etc., can solve the problems of high brittleness of noodles, noodle chopping, high labor intensity, etc., achieve the goal of short time, improve processing efficiency and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

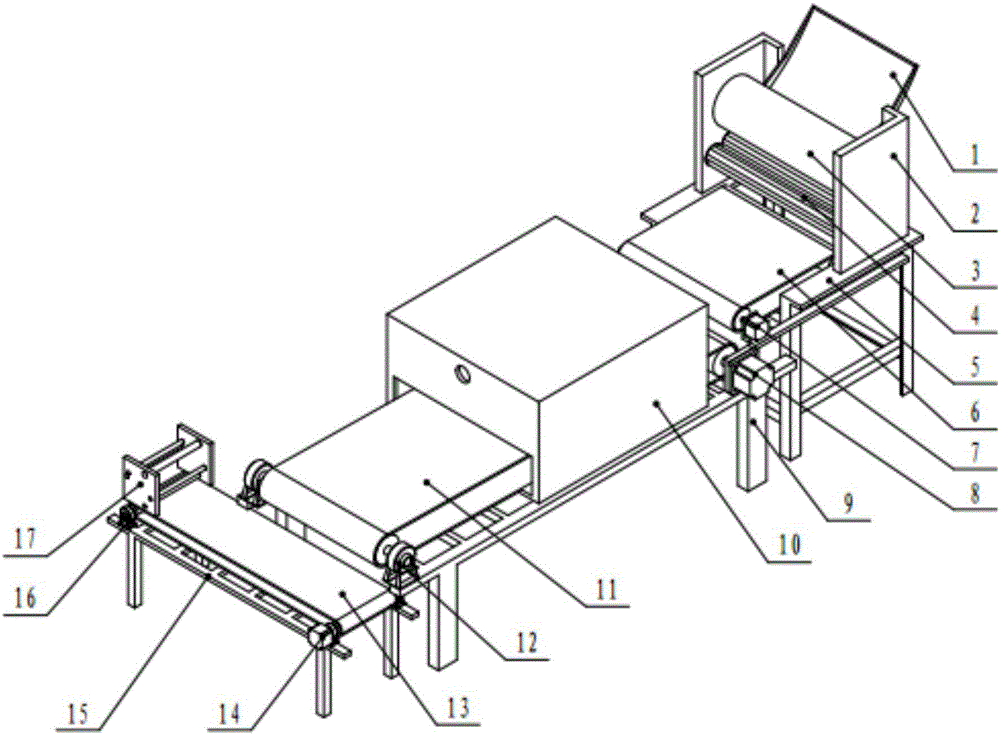

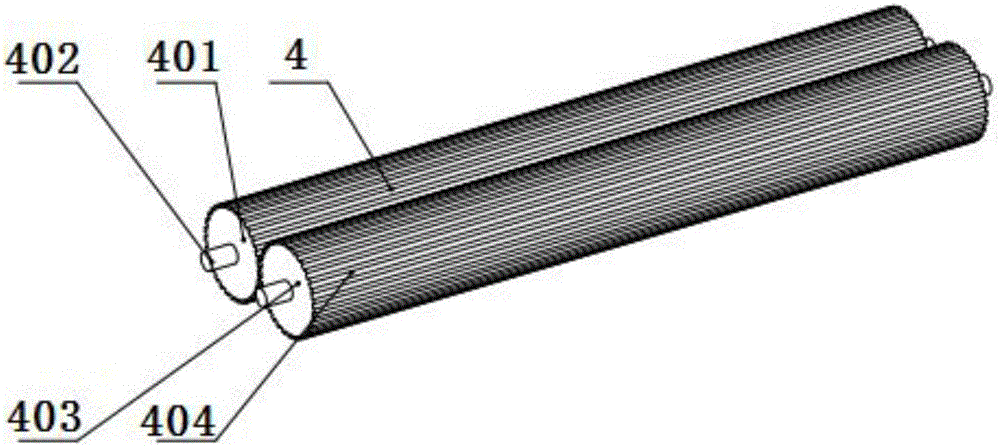

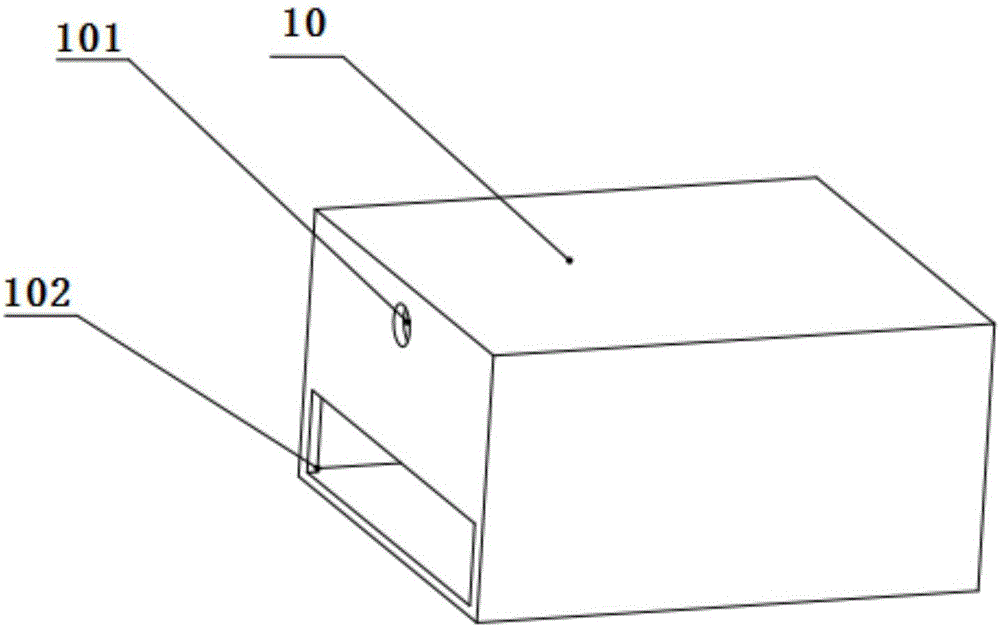

[0012] A device for automatically drying and packaging fixed-length noodles, which is composed of a baffle plate 1, a noodle machine shell 2, a noodle roller 3, a noodle extruding knife 4, a noodle machine support frame 5, a first conveyor belt 6, and a first stepping motor 7. The second stepper motor 8, the first conveyor belt bracket 9, the microwave dryer 10, the second conveyor belt 11, the first conveyor belt bearing bracket 12, the third conveyor belt 13, the third stepper motor 14, the second conveyor belt bracket 15 , the second conveyor belt bearing support 16 and the packaging machine 17 are formed, the noodle extruding knife 4 is made up of a first extruding knife 401 and a second extruding knife 403, and the extruding knife has an extruding knife transmission shaft 402, Extrusion knife groove 404 structure, the microwave dryer 10 has an air flow port 101, a material inlet and outlet 102 structure, the noodle machine shell 2 is installed on the noodle machine support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com