Strontium oxide cluster-modified amorphous carbon nitride photocatalyst and preparation method thereof

A photocatalyst and amorphous technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of increased preparation costs, harsh preparation conditions, etc., to improve performance and solve high preparation costs , excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

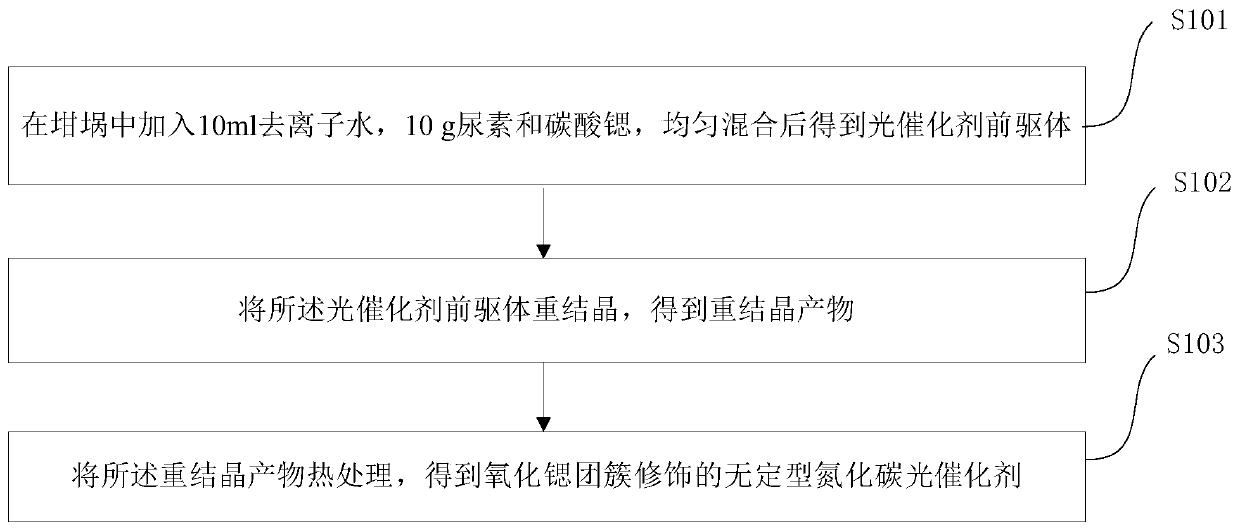

[0042] Please refer to the attached figure 1 , the preparation method of the strontium oxide cluster modified amorphous carbon nitride photocatalyst shown in the embodiment of the present application comprises the following steps:

[0043] S101 Add 10ml of deionized water, 10g of urea and strontium carbonate into the crucible, and mix uniformly to obtain the photocatalyst precursor;

[0044] S102 recrystallize the photocatalyst precursor to obtain a recrystallized product;

[0045] S103 heat-treating the recrystallized product to obtain an amorphous carbon nitride photocatalyst decorated with strontium oxide clusters.

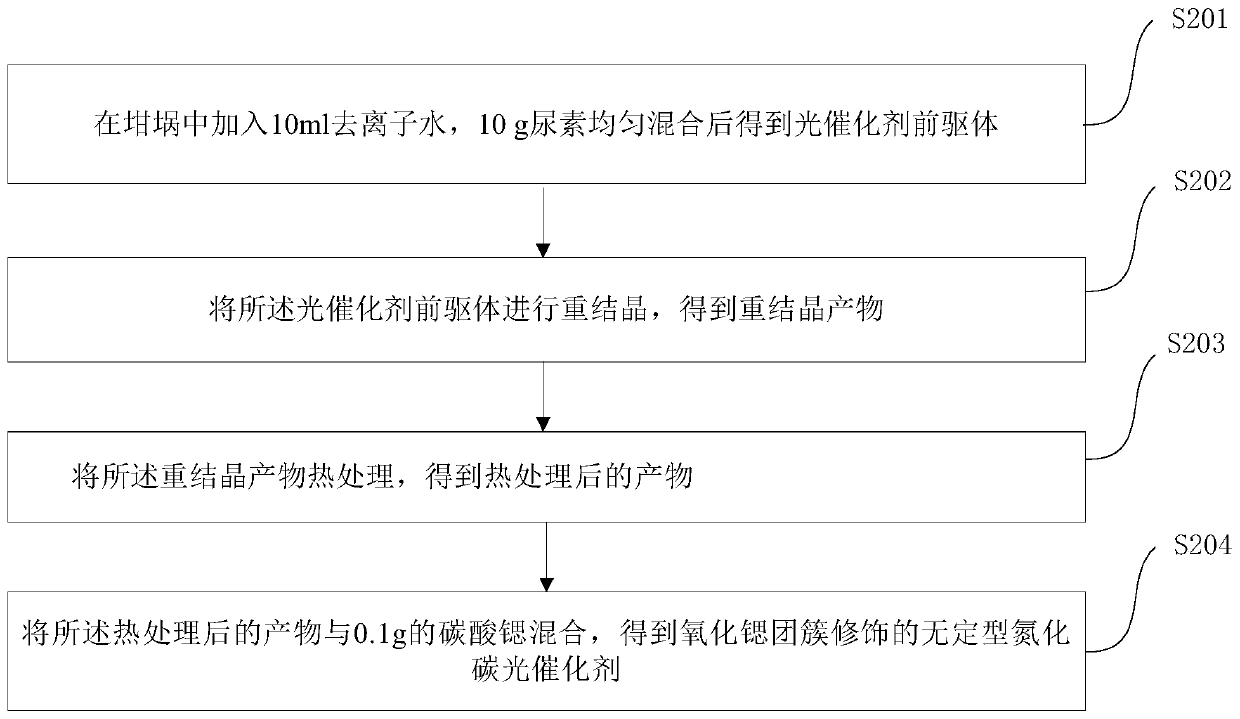

[0046] Please refer to the attached figure 2 , the preparation method of the strontium oxide cluster modified amorphous carbon nitride photocatalyst shown in another embodiment of the present application comprises the following steps:

[0047] S201 Add 10ml of deionized water and 10g of urea into the crucible to obtain the photocatalyst precursor

[0048] ...

Embodiment 1

[0079]Add 10g of urea and 0.06g of strontium carbonate to a 50mL crucible containing 30mL of deionized water, mix them, and disperse them uniformly to obtain a photocatalyst precursor; then recrystallize the precursor in an oven at 60°C; The obtained recrystallized product was heat-treated at 550°C for 2 hours at a heating rate of 15°C / min in a muffle furnace. After the heat treatment, an amorphous carbon nitride photocatalyst decorated with strontium oxide clusters with an added amount of strontium carbonate of 0.06g was obtained. (SCO-U-0.06).

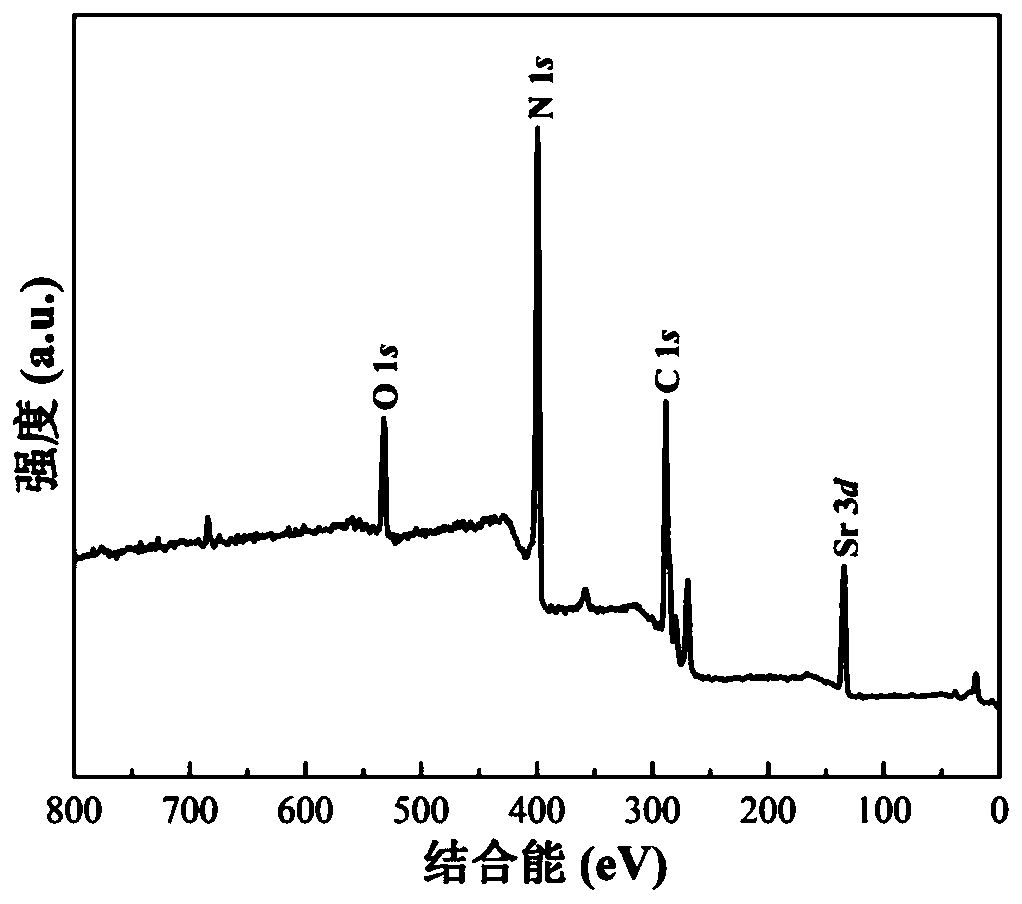

[0080] The amorphous carbon nitride photocatalyst (SCO-U-0.06) modified by strontium oxide clusters with an addition amount of 0.06 g of strontium carbonate prepared in Example 1 of the present application was tested by XPS, XRD, FT-IR, SEM, TEM, HRTEM, Characterized by BET-BJH, PL, time-resolved fluorescence, photocurrent, UV-Vis DRS, and in situ infrared.

[0081] The amorphous carbon nitride photocatalyst (SCO-U-0.06) modified by...

Embodiment 2

[0083] Add 10g of urea and 0.1g of strontium carbonate to a 50mL crucible containing 30mL of deionized water, mix them, and disperse them evenly to obtain a photocatalyst precursor; then recrystallize the precursor in an oven at 60°C; The obtained recrystallized product was heat-treated at 550°C for 2 hours at a heating rate of 15°C / min in a muffle furnace. After the heat treatment, an amorphous carbon nitride photocatalyst decorated with strontium oxide clusters with an addition of 0.1 g of strontium carbonate was obtained. (SCO-U-0.1).

[0084] The characterization of the strontium oxide cluster-modified amorphous carbon nitride photocatalyst (SCO-U-0.1) prepared in Example 2 of the present application with an addition of 0.1 g of strontium carbonate and the NO degradation test process are the same as in Example 1. It is calculated that the NO degradation rate of the SCO-U-0.1 photocatalyst prepared in Example 2 of the present application is 49.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com