Method of manufacturing surface cross-scale functional micro-nano structure

A manufacturing method and technology of micro-nano structure, which are applied in the fields of nanostructure manufacturing, specific nanostructure formation, manufacturing tools, etc., can solve the problems of low manufacturing efficiency, complex process, high cost, etc., and achieve high processing efficiency, good application prospects, The effect of low-cost manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

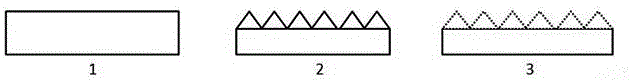

[0017] Such as figure 1 As shown, using a millisecond pulsed laser, using a triangular mask to modulate the beam shape into a triangular spot with a side length of 100 μm at the focal point, using an output power of 200W and a pulse frequency of 1KHz, first along the X-axis direction on the surface of a 5mm titanium alloy ( A high-speed galvanometer is used for scanning on the vertical direction of the bottom edge of the triangular spot, with a scanning distance of 100 μm and a speed of 5 mm / s. After the whole surface scanning process is completed, the titanium alloy workpiece is rotated 90° (Y axis), and then scanned again with the same parameters, and finally the etching process of the conical microstructure (cone) is completed.

[0018] Then use femtosecond pulsed laser, pulse width of 150fs, pulse frequency of 10KHz, spot size of 50μm, first scan and irradiate on the surface of the processed cone along the X-axis direction with a high-speed galvanometer, the scanning dista...

Embodiment 2

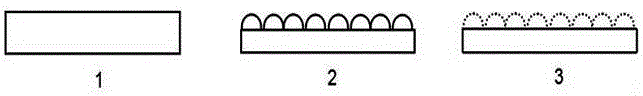

[0020] Such as figure 2 As shown, using a millisecond pulsed laser, using an hourglass-shaped mask to modulate the beam shape into an hourglass-shaped spot with a side length of 300 μm at the focal point, using an output power of 200W and a pulse frequency of 1KHz, the surface of the 5mm aluminum alloy is first along the X-axis The direction is scanned by a high-speed galvanometer with a scanning distance of 300 μm and a speed of 5 mm / s. After the whole surface scanning process is completed, the aluminum alloy workpiece is rotated 90° (Y axis), and then scanned again with the same parameters, and finally the etching process of the semicircular microstructure is completed.

[0021] Then use femtosecond pulsed laser, pulse width of 100fs, pulse frequency of 12KHz, spot size of 100μm, first scan and irradiate the processed semicircular microstructure surface along the X-axis direction with a high-speed galvanometer, and the scanning distance is 100μm , speed 5mm / s. After scann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com