Manufacturing technique of high-activity uranium nitride powder

A manufacturing process, uranium nitride technology, which is applied in the field of nuclear engineering, can solve the problems of complex preparation process, poor powder activity, and small particle size, and achieve good activity, easy oxidation, and small particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

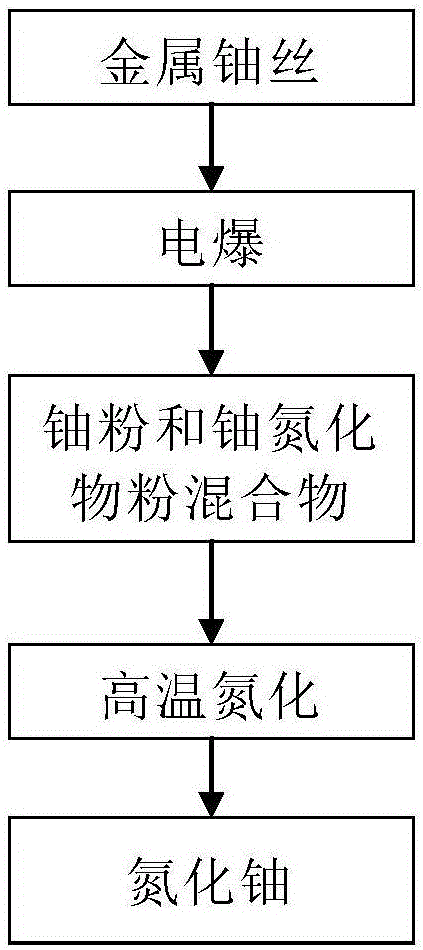

[0027] Embodiment 1: According to figure 1 The process flow shown prepares uranium nitride, and the specific process is as follows:

[0028] (1) After taking out the metal uranium wire with a diameter of about 0.3mm sealed and stored, put it into the electric explosion experimental device;

[0029] (2) Carry out evacuation and nitrogen filling to the electric explosion vessel for 3 times, the purity of the filled nitrogen is 99.99%, and the oxygen impurity content in the nitrogen is less than 10ppm;

[0030] (3) Set the voltage of the electric explosion experimental device to 40KV, and the frequency of electric explosion to 1 time / min;

[0031] (4) Start the electric explosion experimental device, and complete the electric explosion of metal uranium wire under nitrogen environment;

[0032] (5) Seal and collect the mixture of uranium powder and uranium nitride powder generated in the electric explosion experimental device;

[0033] (6) Fill nitrogen and heat the mixture of ...

Embodiment 2

[0034] Example 2: Adjust the voltage of the electric explosion experiment device to 45KV, and the frequency of electric explosion to 2 times / min. High-activity uranium nitride powder is also obtained, and the pellet density after powder pressing and sintering is greater than 90%. Specific steps are as follows:

[0035] (1) After taking out the metal uranium wire with a diameter of about 0.3mm sealed and stored, put it into the electric explosion experimental device;

[0036] (2) Carry out evacuation and nitrogen filling to the electric explosion vessel for 3 times, the purity of the filled nitrogen is 99.99%, and the oxygen impurity content in the nitrogen is less than 10ppm;

[0037] (3) The voltage of the electric explosion experimental device is set to 45KV, and the frequency of electric explosion is 2 times / min;

[0038] (4) Start the electric explosion experimental device, and complete the electric explosion of metal uranium wire under nitrogen environment;

[0039] (5)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com