Nitrogen plasma modified three-dimensional graphene powder, and preparation and application of graphene powder

A plasma, graphene powder technology, applied in electrical components, photosensitive equipment, inorganic chemistry, etc., can solve the problems of large electrode thickness, unfavorable battery packaging and practical application, increase battery cost, etc., achieve excellent electrical conductivity, achieve large Batch preparation, strong universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment provides a method for growing a three-dimensional graphene powder with a large specific surface area by using a vertical fluidized bed vapor-phase chemical deposition method, which includes the following steps:

[0050] Under normal pressure, feed Ar (1000 sccm / min), raise the temperature of the heating furnace in the fluidized bed to 950 ° C, and the heating rate is 5 ° C / min; after reaching the reaction temperature, feed CH 4 Gas (800sccm / min);

[0051] At the same time, add 20g of magnesium oxide template from the top of the fluidized bed, and the reaction time is 20min;

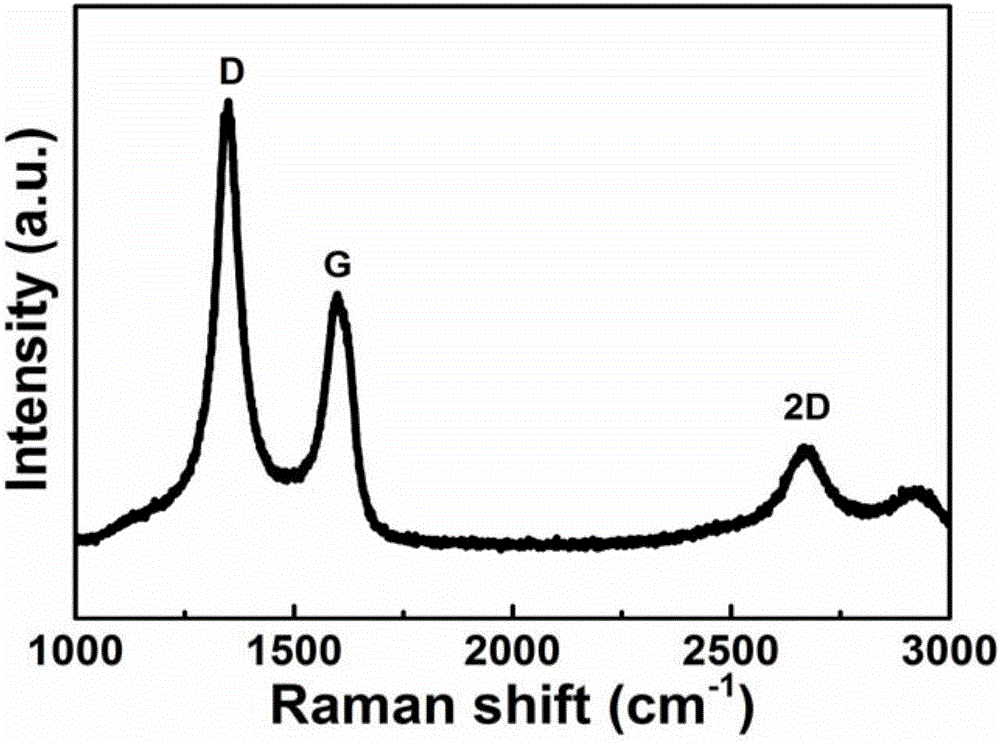

[0052] After reaching the reaction time, stop feeding CH 4 gas, stop heating and cool to room temperature naturally. Open the furnace, take out the black product, pickle and purify to remove the template, filter it, put it in a vacuum oven and dry it at 50°C for 10 hours to completely remove water; thus obtain a large specific surface area three-dimensional graphene powder raw mat...

Embodiment 2

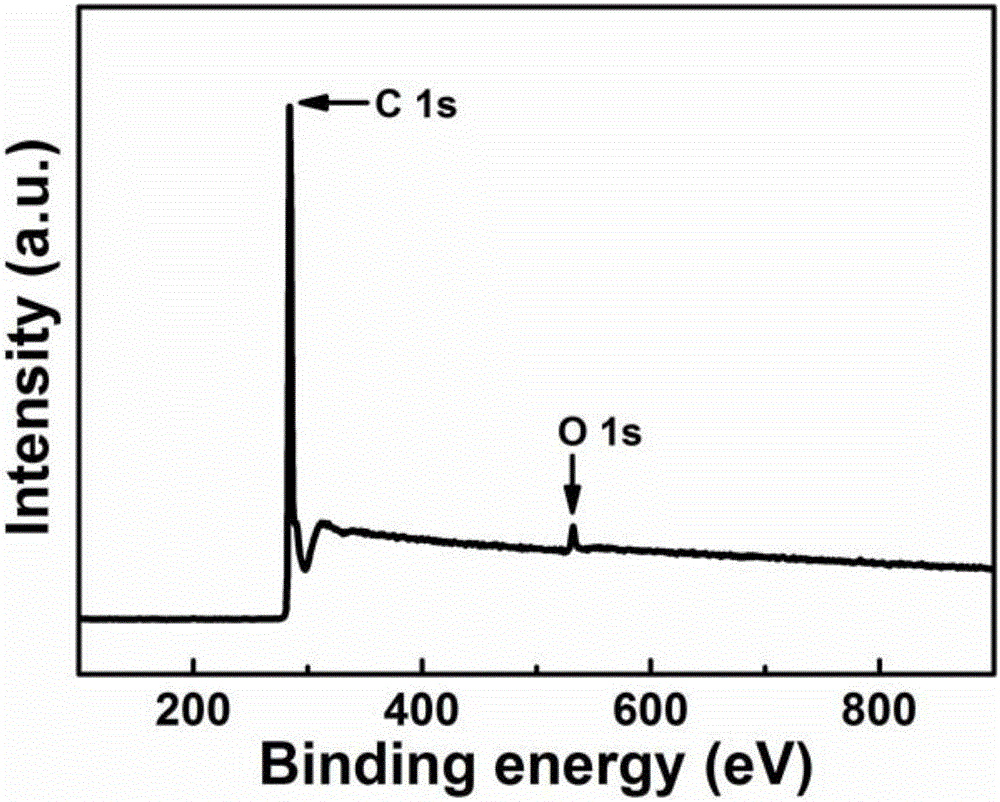

[0056] The present embodiment provides a kind of preparation method of three-dimensional graphene powder modified by nitrogen plasma, which comprises the following steps:

[0057] (1), the three-dimensional graphene powder with large specific surface area prepared in Example 1 is placed in a vacuum oven and dried at 40° C. for 2 hours to completely remove moisture;

[0058] (2), place the three-dimensional graphene powder with large specific surface area after drying in the plasma equipment (the schematic diagram is as follows Figure 15 (shown) on the bottom electrode in the chamber, adjust the top electrode so that the distance between the bottom electrode and the top electrode is 6 mm, then use a vacuum pump to first drain the air in the chamber, then pass nitrogen to normal pressure, and then pump the nitrogen Dry, and finally feed nitrogen with a flow rate of 170sccm / min until the pressure in the chamber is 470Pa;

[0059] (3) After the pressure in the chamber of the pla...

Embodiment 3

[0062] The present embodiment provides a kind of preparation method of three-dimensional graphene powder modified by nitrogen plasma, which comprises the following steps:

[0063] (1), the three-dimensional graphene powder with large specific surface area prepared in Example 1 is placed in a vacuum oven and dried at 40° C. for 2 hours to completely remove moisture;

[0064] (2), place the dried large specific surface area three-dimensional graphene powder on the bottom electrode in the chamber of the plasma equipment, adjust the top electrode so that the distance between the bottom electrode and the top electrode is 6 mm, and then use a vacuum pump to first The air in the chamber is drained, then nitrogen is introduced to normal pressure, then the nitrogen is drained, and finally nitrogen is introduced at a flow rate of 170 sccm / min until the pressure in the chamber is 470Pa;

[0065] (3) After the pressure in the chamber of the plasma equipment is stabilized, turn on the high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com