Utilization method of glauberite ore

A kind of glauberite and pulp technology, which is applied in the field of glauberite utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

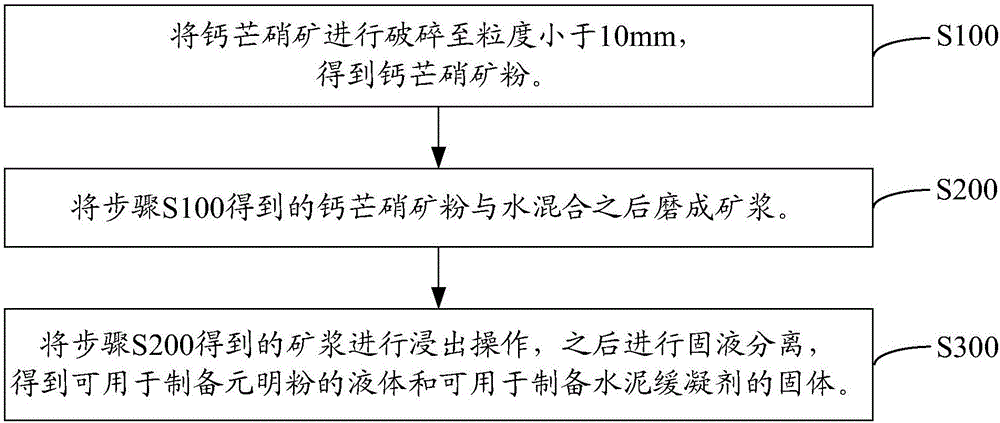

Image

Examples

Embodiment 1

[0050] The main components of the glauberite ore of this embodiment are shown in Table 1.

[0051] The main component of the glauberite ore of table 1 embodiment 1

[0052] Element Glauber's salt dolomite quartz Kaolinite Mica Content (wt%) 70 8.9 8.7 5.4 2.3

[0053] The utilization method of glauberite ore is as follows:

[0054] Glauberite ore is sequentially subjected to coarse crushing, medium crushing and fine crushing until the particle size is less than 10 mm to obtain Glauberite ore powder.

[0055] The glauberite ore powder is added into a wet ball mill to grind into ore pulp, the concentration of the ball milled ore pulp is controlled to 50wt%, and the particle size of the glauberite ore after ball milling is less than 0.45mm.

[0056] Pump the pulp into the continuous countercurrent leaching device, adjust the concentration of the leaching pulp to 50wt%, maintain the leaching temperature at 30°C, stir and leaching for 120min, use...

Embodiment 2

[0060] The main components of the glauberite ore of this embodiment are shown in Table 2.

[0061] The main component of the glauberite ore of table 2 embodiment 2

[0062] Element Glauber's salt dolomite quartz Kaolinite Mica Content (wt%) 60 11 12 8 2.4

[0063] The utilization method of glauberite ore is as follows:

[0064] Glauberite ore is sequentially subjected to coarse crushing, medium crushing and fine crushing until the particle size is less than 10 mm to obtain Glauberite ore powder.

[0065] Put the glauberite ore powder into a wet ball mill to grind into ore pulp, the concentration of the ball milled ore pulp is controlled to 80wt%, and the particle size of the glauberite ore after ball milling is less than 0.18mm.

[0066] Pump the pulp into the continuous countercurrent leaching device, adjust the concentration of the leached pulp to 40wt%, maintain the leaching temperature at 50°C, stir and leaching for 60min, use a plate an...

Embodiment 3

[0070] The main components of the glauberite ore of this embodiment are shown in Table 3.

[0071] The main component of the glauberite ore of table 3 embodiment 3

[0072] Element Glauber's salt dolomite quartz Kaolinite Mica Content (wt%) 73 8 7.6 4.9 2

[0073] The utilization method of glauberite ore is as follows:

[0074] Glauberite ore is sequentially subjected to coarse crushing, medium crushing and fine crushing until the particle size is less than 10 mm to obtain Glauberite ore powder.

[0075] Put the glauberite ore powder into a wet ball mill to grind into ore pulp, the concentration of the ball milled ore pulp is controlled to 65wt%, and the particle size of the glauberite ore after ball milling is less than 0.30mm.

[0076] Pump the pulp into the continuous countercurrent leaching device, adjust the concentration of the leaching pulp to 46wt%, maintain the leaching temperature at 60°C, stir and leaching for 30min, use a plate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com