A kind of cobalt-doped cerium oxide nanomaterial with sheet structure and its preparation and application

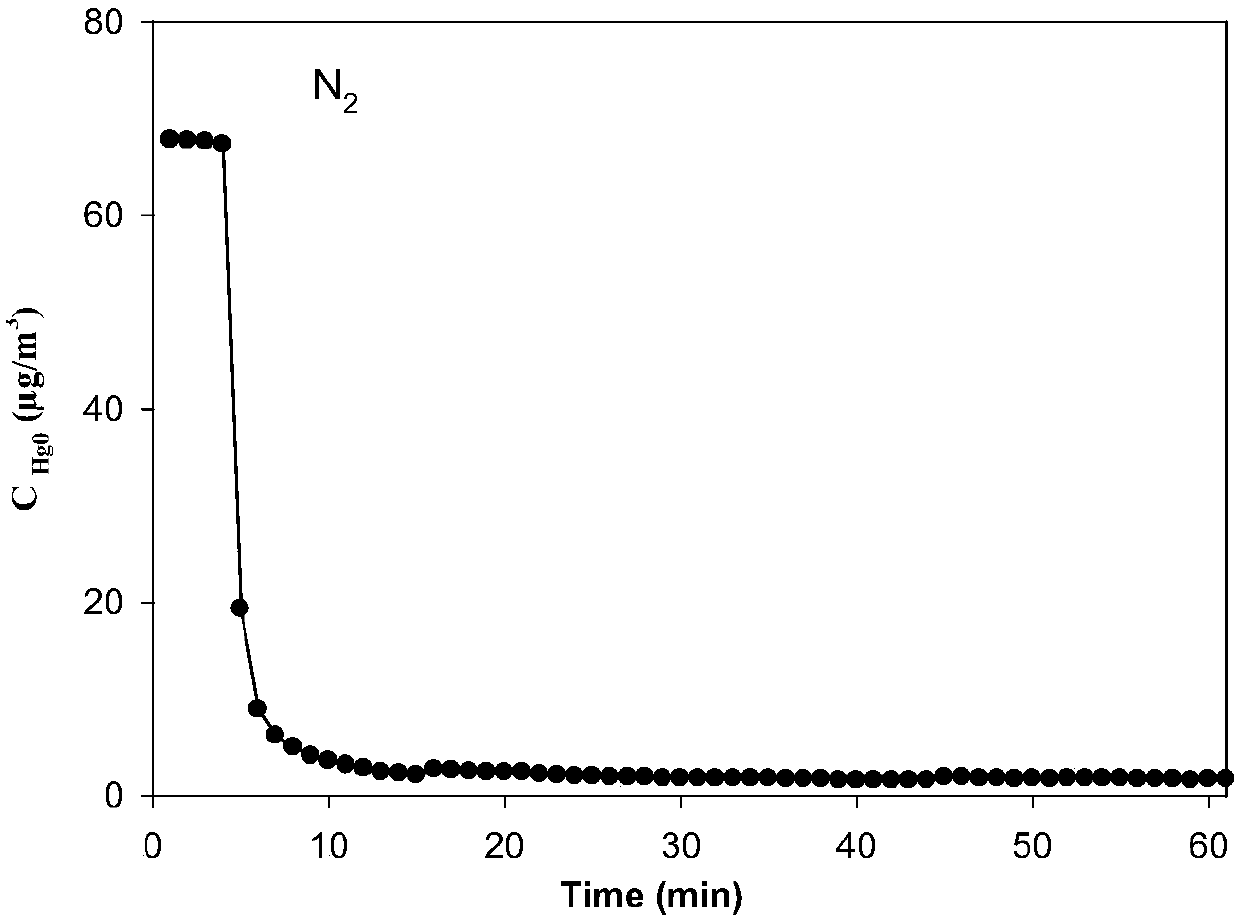

A sheet-like structure, nanomaterial technology, applied in nanotechnology, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of difficult popularization and application, insufficient cleanliness and energy saving, complex raw materials, etc., and achieves good mercury removal effect and surface oxygen content. And the effect of improving oxygen storage capacity, increasing reaction sites and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

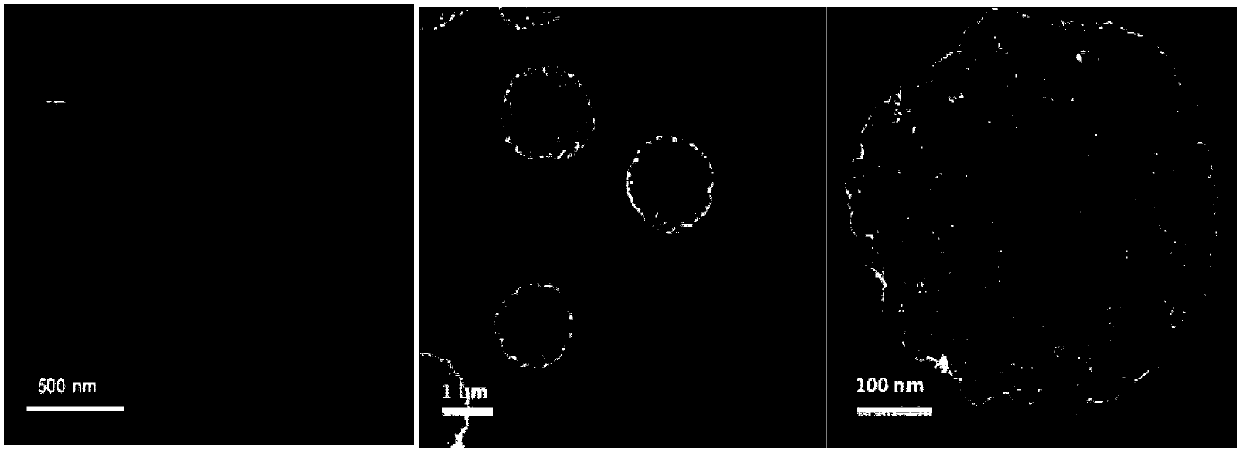

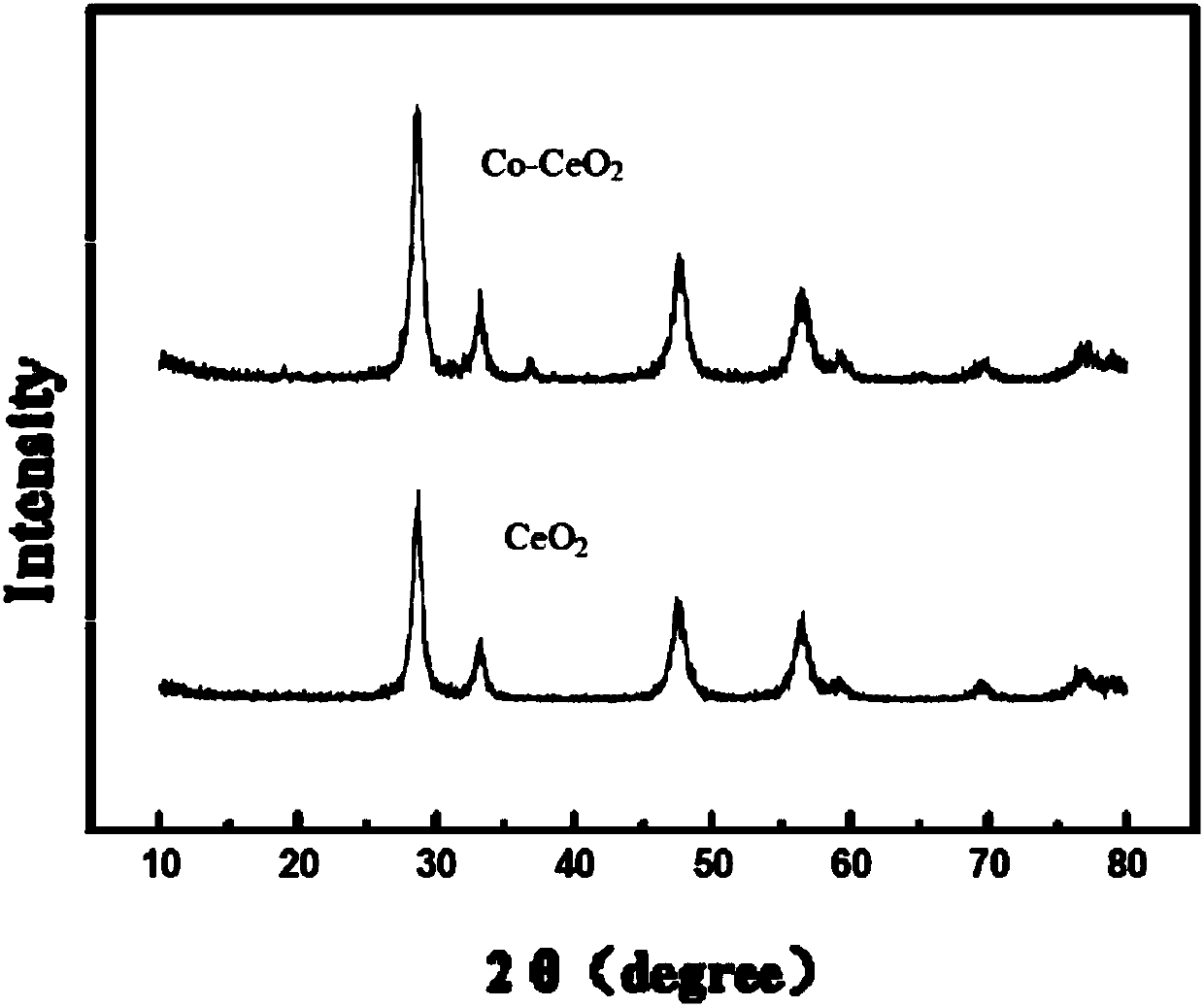

[0027] Add 0.143g of cerium nitrate, 0.095g of cobalt chloride and 0.5g of polyvinylpyrrolidone into 30mL of deionized water, stir magnetically for 10min until it is completely dissolved, then add 2.196g of urea into the reaction solution, stir for 30min, and add the mixture to In a hydrothermal reactor. Put the reaction kettle into an oven and keep the temperature at 150°C for 10h. Then the resulting mixed solution was washed three times with deionized water and twice with ethanol, dried in an oven at 60°C for 10 hours, and finally calcined in a muffle furnace at 500°C for 4 hours to obtain a cobalt-doped cerium oxide flake nanomaterial.

Embodiment 2

[0029] Add 0.143g of cerium nitrate, 0.062g of cobalt acetate and 0.5g of polyvinylpyrrolidone into 30mL of deionized water, stir magnetically for 10min until it is completely dissolved, then add 2.196g of urea into the reaction solution, stir for 30min, and add the mixture to the water in a hot reactor. Put the reaction kettle into an oven and keep the temperature at 150°C for 10h. Then the resulting mixed solution was washed three times with deionized water and twice with ethanol, dried in an oven at 60°C for 10 hours, and finally calcined in a muffle furnace at 500°C for 4 hours to obtain a cobalt-doped cerium oxide flake nanomaterial.

Embodiment 3

[0031] Add 0.143g of cerium nitrate, 0.073g of cobalt nitrate and 0.5g of polyvinylpyrrolidone into 30mL of deionized water, stir magnetically for 10min until it is completely dissolved, then add 2.196g of urea into the reaction solution, stir for 30min, and add the mixture to the water in a hot reactor. Put the reaction kettle into an oven and keep the temperature at 150°C for 10h. Then the resulting mixed solution was washed three times with deionized water and twice with ethanol, dried in an oven at 60°C for 10 hours, and finally calcined in a muffle furnace at 500°C for 4 hours to obtain a cobalt-doped cerium oxide flake nanomaterial.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com