A kind of cobalt oxide/nitrogen co-doped carbon nanotube composite material and its preparation and application

A technology of carbon nanotubes and cobalt oxides, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high cost, limited application, complex synthesis process, etc., and improve the binding force , good effect and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

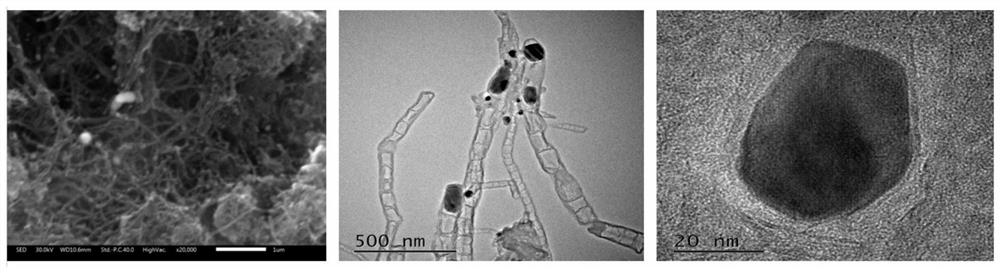

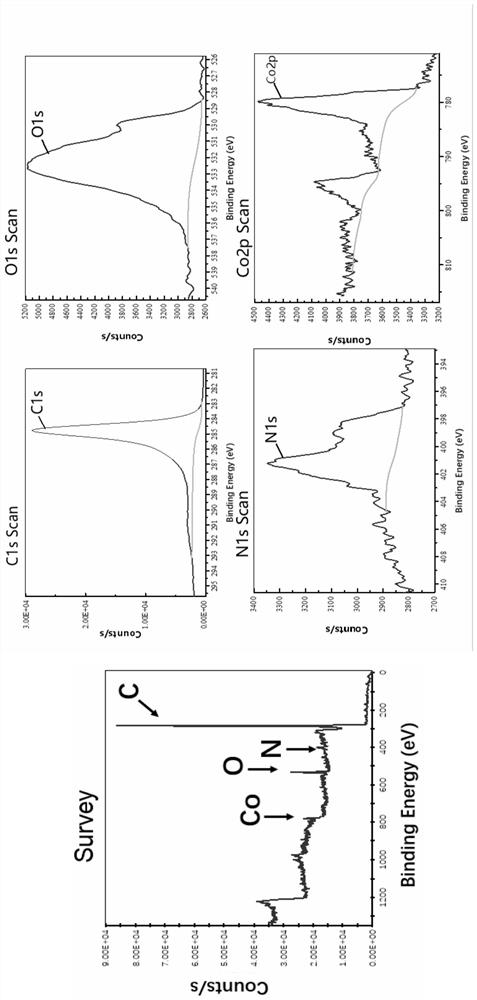

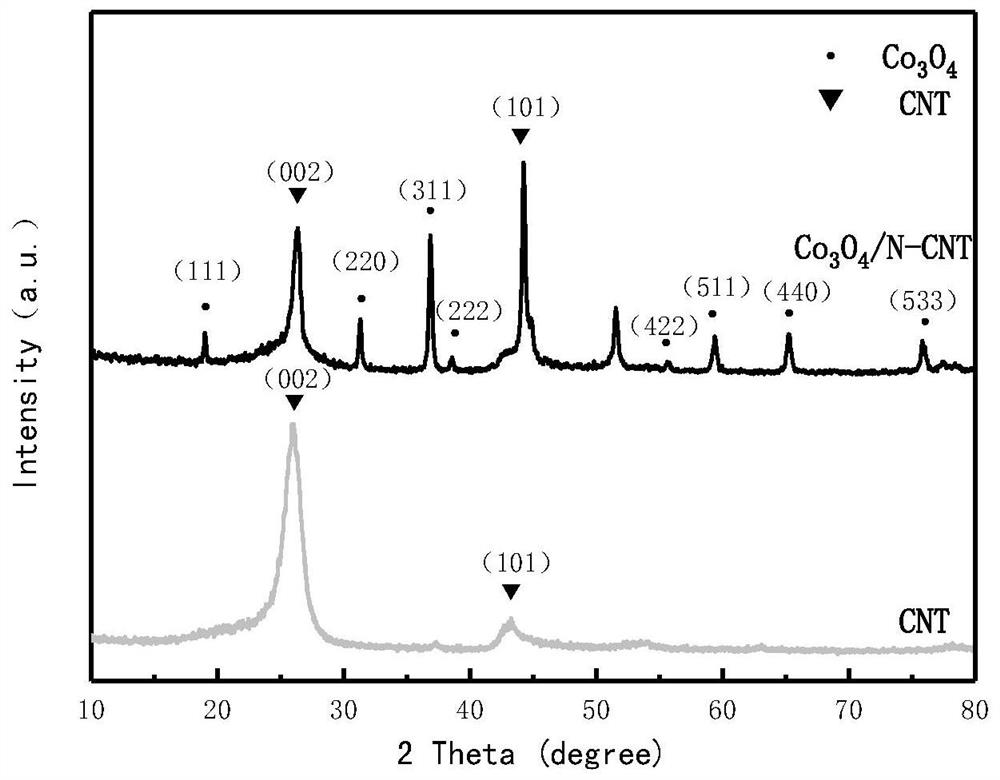

Embodiment 1

[0035] Add 3g of dicyandiamide, 1.46g of cobalt nitrate and 0.5g of polyvinylpyrrolidone into 80mL of deionized water, stir magnetically for 10min until it is completely dissolved, then add 2.196g of urea into the reaction solution, stir for 30min, and put the mixture into an ultrasonic In the reactor, the ultrasonic power is 800W, the stirring speed is 700r / min, and the heating temperature is 80°C until it is completely dry. Then the resulting mixture was transferred to a tube furnace with a nitrogen atmosphere, the heating rate was 3°C / min, and the temperature was kept at 700°C for 3 hours. The obtained material was washed with 1mol / L hydrochloric acid to remove excess cobalt ions, and then washed three times with pure water, ethanol Wash three times, filter with suction, and dry in an oven at 60° C. for 4 hours to obtain a cobalt oxide / nitrogen co-doped carbon nanotube composite material.

Embodiment 2

[0037]Add 3g of dicyandiamide, 0.73g of cobalt nitrate and 0.5g of polyvinylpyrrolidone into 80mL of deionized water, stir magnetically for 10min until it is completely dissolved, then add 2.196g of urea into the reaction solution, stir for 30min, and put the mixture into the ultrasonic In the reactor, the ultrasonic power is 800W, the stirring speed is 700r / min, and the heating temperature is 80°C until it is completely dry. Then the resulting mixture was transferred to a tube furnace with a nitrogen atmosphere, the heating rate was 3°C / min, and the temperature was kept at 700°C for 3 hours. The obtained material was washed with 1mol / L hydrochloric acid to remove excess cobalt ions, and then washed three times with pure water, ethanol Wash three times, filter with suction, and dry in an oven at 60° C. for 4 hours to obtain a cobalt oxide / nitrogen co-doped carbon nanotube composite material.

Embodiment 3

[0039] Add 3g of dicyandiamide, 1.24g of cobalt acetate and 0.5g of polyvinylpyrrolidone into 80mL of deionized water, stir magnetically for 10min until it is completely dissolved, then add 2.196g of urea into the reaction solution, stir for 30min, and put the mixture into an ultrasonic In the reactor, the ultrasonic power is 800W, the stirring speed is 700r / min, and the heating temperature is 80°C until it is completely dry. Then the resulting mixture was transferred to a tube furnace with a nitrogen atmosphere, the heating rate was 3°C / min, and the temperature was kept at 700°C for 3 hours. The obtained material was washed with 1mol / L hydrochloric acid to remove excess cobalt ions, and then washed three times with pure water, ethanol Wash three times, filter with suction, and dry in an oven at 60° C. for 4 hours to obtain a cobalt oxide / nitrogen co-doped carbon nanotube composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com