A ring-shaped copper-doped cerium oxide nanomaterial and its preparation and application

A technology of nanomaterials and ring structures, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve problems such as the difference in catalytic performance of cerium oxide nanomaterials, and achieve Good mercury removal effect, enhanced activity, enhanced catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

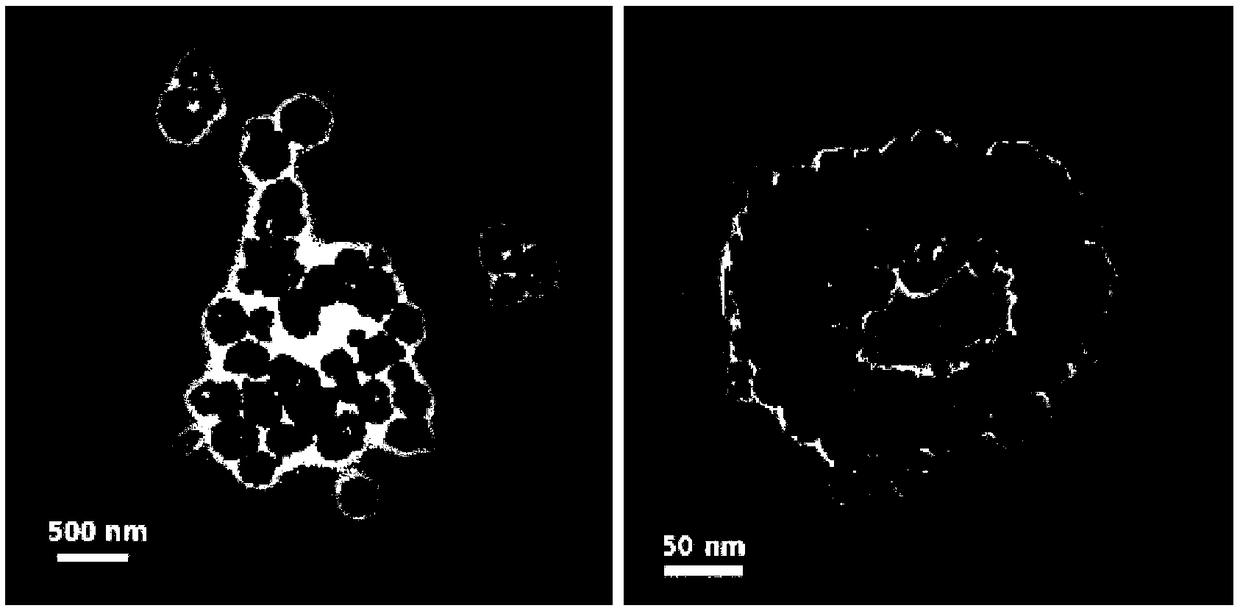

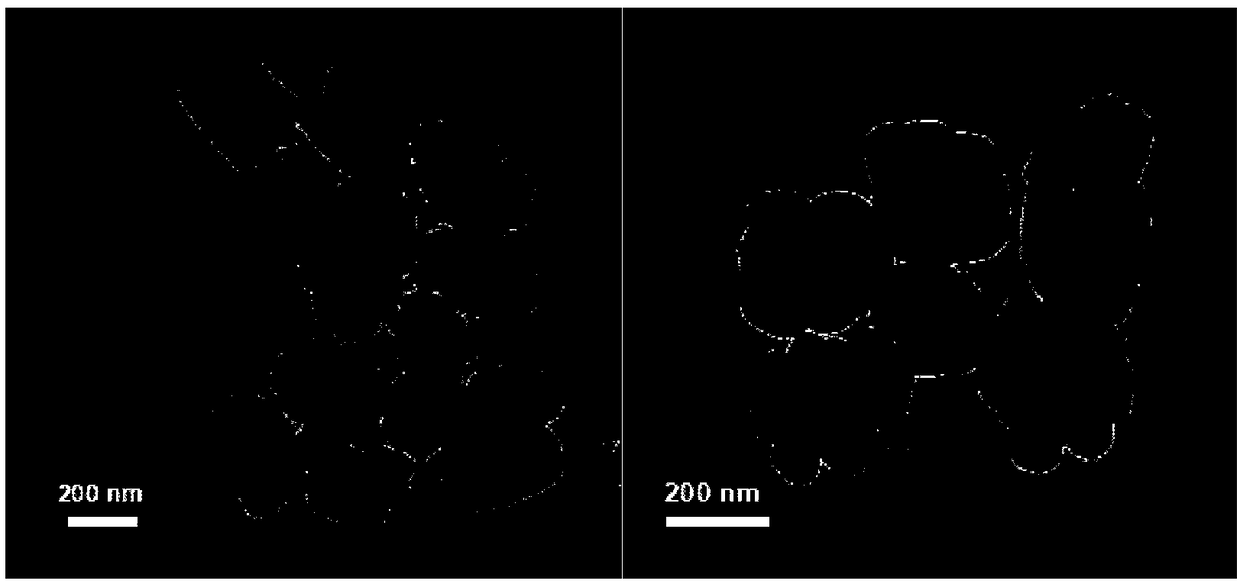

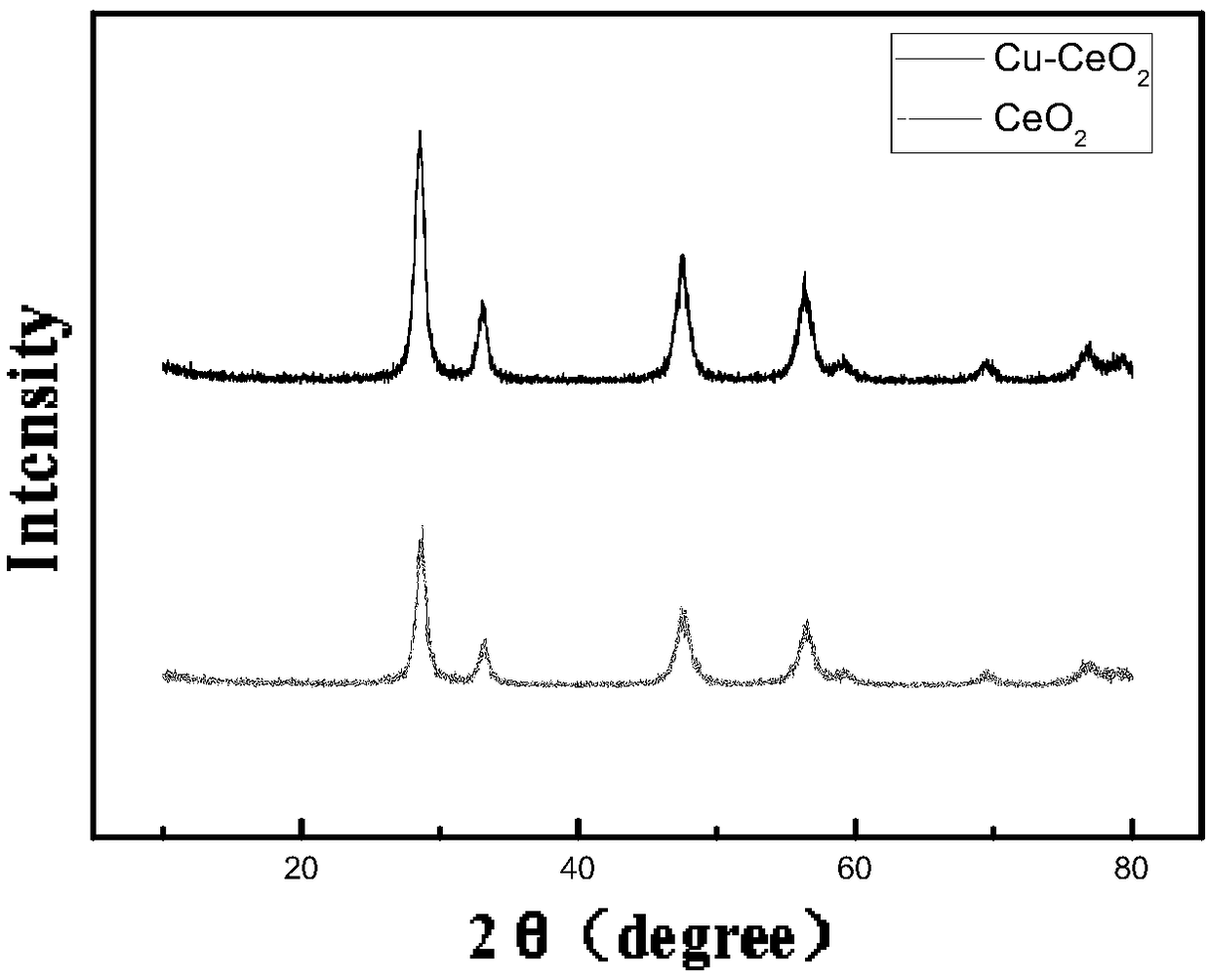

[0026] Add 0.143g of cerium nitrate, 0.068g of copper chloride and 0.5g of polyvinylpyrrolidone into 30mL of deionized water, stir magnetically for 10min until it is completely dissolved, then add 2.196g of urea into the reaction solution, stir for 30min, and add the mixture to In a hydrothermal reactor. Put the reaction kettle into an oven and keep the temperature at 150°C for 10h. Then the obtained mixed solution was washed three times with deionized water and twice with ethanol, dried in an oven at 60° C. for 10 hours, and finally calcined in a muffle furnace at 500° C. for 4 hours to obtain a ring-shaped nanomaterial of copper doped cerium oxide.

Embodiment 2

[0028] Add 0.143g of cerium nitrate, 0.097g of copper nitrate and 0.5g of polyvinylpyrrolidone into 30mL of deionized water, stir magnetically for 10min until it is completely dissolved, then add 2.196g of urea into the reaction solution, stir for 30min, and add the mixture to the hydrothermal in the reactor. Put the reaction kettle into an oven and keep the temperature at 150°C for 10h. Then the obtained mixed solution was washed three times with deionized water and twice with ethanol, dried in an oven at 60° C. for 10 hours, and finally calcined in a muffle furnace at 500° C. for 4 hours to obtain a ring-shaped nanomaterial of copper doped cerium oxide.

Embodiment 3

[0030] Under the condition of 200°C, the materials prepared in Example 1 were used as the catalyst treatment concentration of 75 μg / m 3 Hg 0 Steam, space velocity is 150000h -1 , at N 2 Under the condition of carrier gas, after feeding 4% oxygen, the mercury removal effect can reach more than 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com