A nitrogen, sulfur co-doped porous carbon sheet capacitive desalination electrode material and its preparation and application

A technology of electrode material and porous carbon, which is applied in the field of capacitive desalination electrode material preparation, can solve the problems of limiting the application of capacitive desalination technology and low desalination amount, and achieves simple, clean and controllable preparation process, good desalination effect, and high surface wettability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Electrode Preparation for Capacitive Desalting

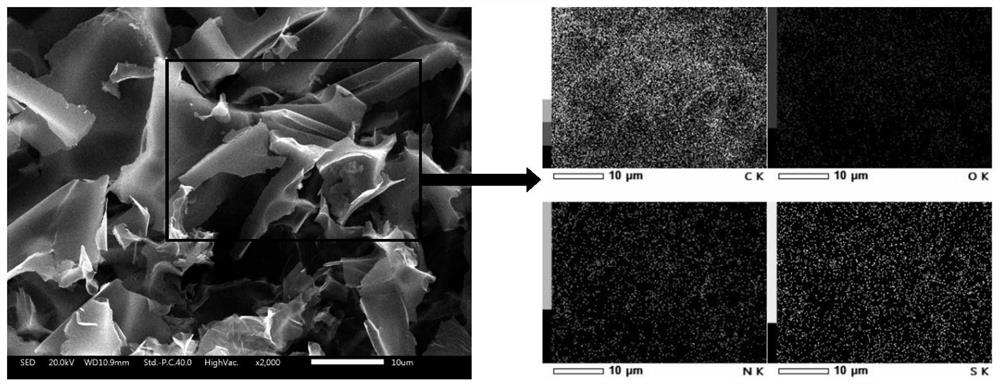

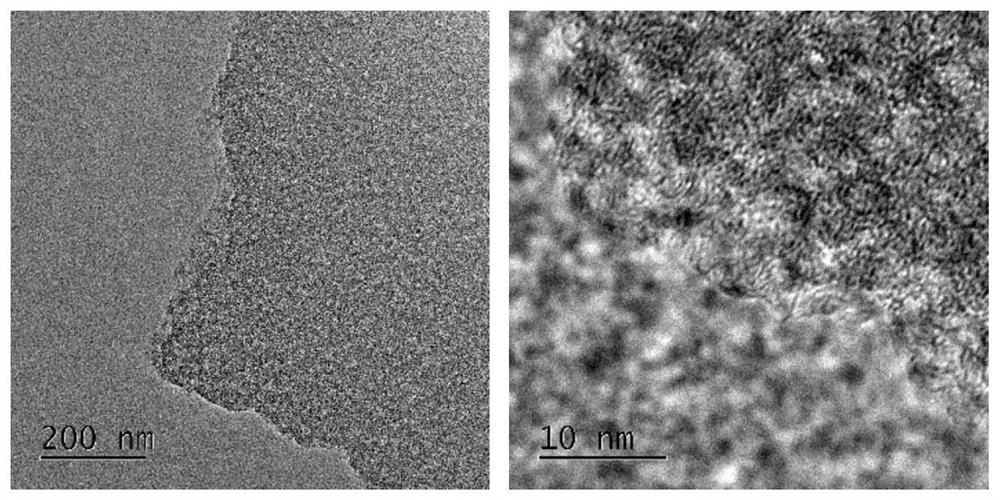

[0049] The mass ratio between the mixture of potassium chloride and lithium chloride, the mixture of lithium nitrate and sodium thiosulfate, and glucose in the mixture is 10:1:1, and the mass ratio of potassium chloride to lithium chloride The mass ratio of lithium nitrate and sodium thiosulfate is 1:4. The stirring time is 30 minutes, the carbonization process is carried out under an inert atmosphere, the heating rate is 5°C / min, the holding temperature is 500°C, and the holding time is 2h. The high-temperature carbonization product is cooled, soaked in water for 10 hours, filtered, and then dried in an oven at 60°C for 24 hours to obtain a nitrogen-sulfur co-doped porous carbon sheet, see figure 1 . Using nitrogen adsorption and desorption, X-ray diffraction and X-ray diffraction photoelectron can analyze the synthesized porous carbon sheet, which proves that it has the characteristics of high specific surface area, ...

Embodiment 2

[0052] 1) Preparation of Capacitive Desalting Electrode

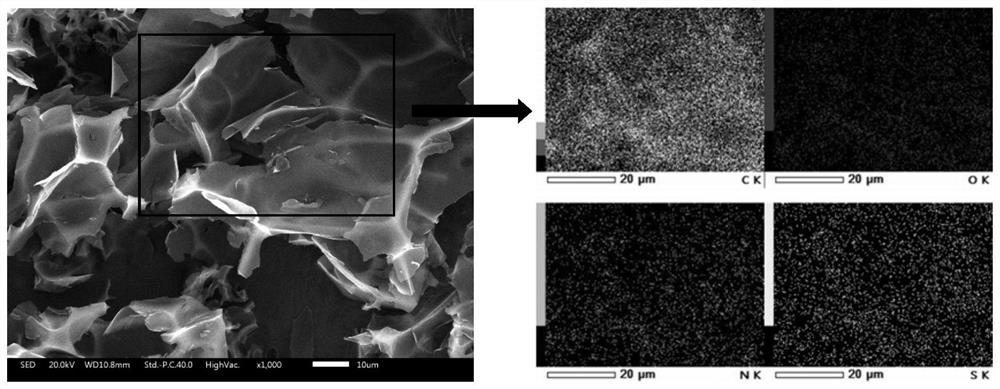

[0053] The mass ratio between the mixture of potassium chloride and lithium chloride, the mixture of lithium nitrate and sodium thiosulfate, and glucose in the mixture is 10:1:1, and the mass ratio of potassium chloride to lithium chloride The mass ratio of lithium nitrate and sodium thiosulfate is 1:4. The stirring time is 30 min, the carbonization process is carried out under an inert atmosphere, the heating rate is 5°C / min, the holding temperature is 600°C, and the holding time is 2h. The high-temperature carbonization product is cooled, soaked in water for 10 hours, filtered, and then dried in an oven at 60°C for 24 hours to obtain a nitrogen-sulfur co-doped porous carbon sheet (named CNSs-600), see figure 2 . The synthesized porous carbon sheet can be analyzed by nitrogen adsorption and desorption, X-ray diffraction and X-ray diffraction photoelectron, which proves that it has the characteristics of high specifi...

Embodiment 3

[0058] 1) Preparation of Capacitive Desalting Electrode

[0059] The mass ratio between the mixture of potassium chloride and lithium chloride, the mixture of lithium nitrate and sodium thiosulfate, and glucose in the mixture is 10:1:1, and the mass ratio of potassium chloride to lithium chloride The mass ratio of lithium nitrate and sodium thiosulfate is 1:4. The stirring time is 30 minutes, the carbonization process is carried out under an inert atmosphere, the heating rate is 5°C / min, the holding temperature is 700°C, and the holding time is 2h. The high-temperature carbonization product is cooled, soaked in water for 6-10 hours, filtered, and then dried in an oven at 60°C for 12-24 hours to obtain nitrogen and sulfur co-doped porous carbon prepared by nitrogen and sulfur co-doped porous carbon sheets Sheet material, carbon black, PVDF according to the mass ratio of 8:1:1 dry grinding for 10 minutes, then wet grinding with 1-methyl-2-pyrrolidone dropwise for 30 minutes, ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com