Copper oxide electrode material of nano-porous structure and preparation method and application thereof

A nanostructure and electrode material technology, which is applied in the field of controllable synthesis of porous copper oxide materials, can solve problems such as unstable sensitivity, achieve good anti-interference, facilitate electron transmission, and easily react

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

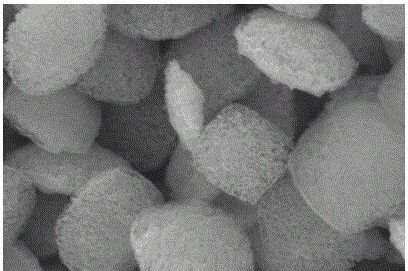

[0035] 1. Preparation process steps:

[0036] (1) Add 50mL of 0.1M copper acetate solution dropwise into 50mL of 0.1M oxalic acid solution, and stir magnetically for 1 hour until the system completely turns into a blue precipitate.

[0037] (2) The blue precipitate was washed three times with deionized water and absolute ethanol, and then dried in an oven at 60°C.

[0038] (3) The dried samples were taken out from the oven and washed with deionized water and absolute ethanol three times, then dried in an oven at 60°C, and then calcined in a tube furnace.

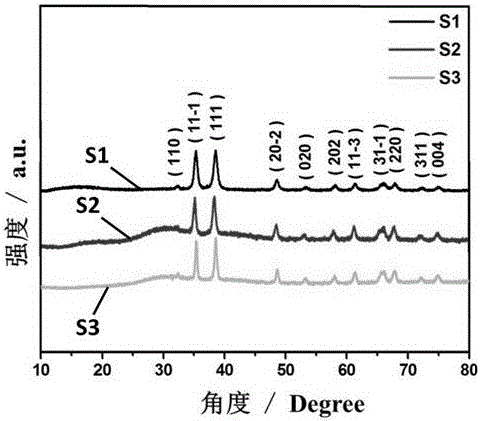

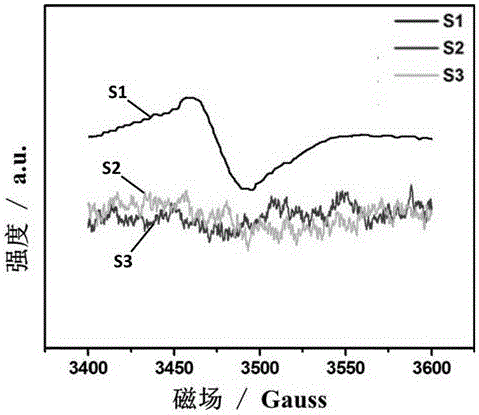

[0039] Calcination conditions: in an air atmosphere, the temperature was raised to 350°C at a rate of 1°C per minute, then kept for 2 hours, and naturally cooled to room temperature to obtain a sample of copper oxide electrode material S1 with a porous nanostructure.

[0040] Parallel test 1: in the air atmosphere, the temperature was raised to 450° C. at a rate of 1° C. per minute, then kept for 2 hours, and naturally cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com