An energy-saving and environmentally friendly masonry mortar

A masonry mortar, energy saving and environmental protection technology, applied in the field of energy saving and environmental protection, can solve problems such as polluted environment, acid water loss, etc., achieve the effect of reducing environmental protection pressure, reducing waste discharge burden, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

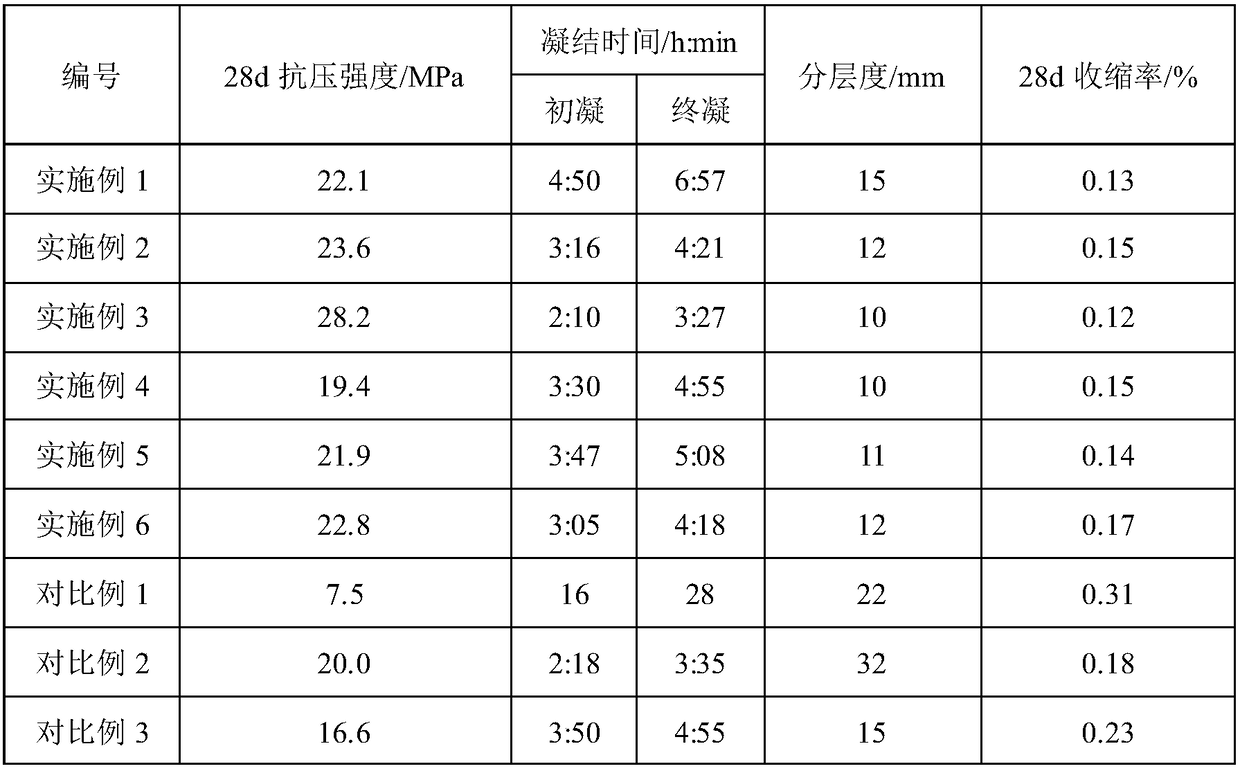

Examples

Embodiment 1

[0031] An energy-saving and environment-friendly masonry mortar, which is composed of the following raw materials in weight percentage: 20% of phosphorus slag powder, 15% of modified alum mud, 8% of cement, 0.01% of viscosity-increasing and water-retaining agent, 0.2% of magnesium aluminum silicate, strength excitation Agent 0.02%, the rest is river sand.

[0032] The specific surface area of the phosphorus slag powder is 400m 2 / kg-500m 2 / kg.

[0033] The preparation method of the modified alum slime is as follows: the wet alum slime produced in the production of alunite is directly put into the reaction tank, and after adding quicklime accounting for 1% of the total weight of the alum sludge and an organic modifier accounting for 0.03% of the total weight of the alum sludge, aging After 26 hours of chemical reaction, drying is obtained to obtain the modified alum sludge.

[0034] The organic modifier is composed of zinc dialkyldithiophosphate and fatty alcohol polyoxye...

Embodiment 2

[0040] An energy-saving and environment-friendly masonry mortar, which is composed of the following raw materials in weight percentage: 25% of phosphorus slag powder, 20% of modified alum mud, 12% of cement, 0.05% of viscosity-increasing and water-retaining agent, 1% of magnesium aluminum silicate, strength excitation Agent 0.08%, the rest is river sand.

[0041] The specific surface area of the phosphorus slag powder is 400m 2 / kg-500m 2 / kg.

[0042] The preparation method of the modified alum slime is as follows: directly put the wet alum slime produced in the production of alunite into the reaction tank, add quicklime accounting for 5% of the total weight of the alum sludge and an organic modifier accounting for 0.05% of the total weight of the alum sludge, and age After 26 hours of chemical reaction, drying is obtained to obtain the modified alum sludge.

[0043] The organic modifier is tetrasodium edetate.

[0044] The cement is P.O42.5 cement.

[0045] The thicke...

Embodiment 3

[0049] An energy-saving and environment-friendly masonry mortar, which is composed of the following raw materials in weight percentage: 22% of phosphorus slag powder, 18% of modified alum mud, 11% of cement, 0.03% of viscosity-increasing and water-retaining agent, 0.5% of magnesium aluminum silicate, strength excitation Agent 0.04%, the rest is river sand.

[0050] The specific surface area of the phosphorus slag powder is 400m 2 / kg-500m 2 / kg.

[0051] The preparation method of the modified alum slime is as follows: directly put the wet alum slime produced in the production of alunite into the reaction tank, add quicklime accounting for 4% of the total weight of the alum sludge and an organic modifier accounting for 0.04% of the total weight of the alum sludge, and age Drying after 25 hours of chemical reaction to obtain the modified alum sludge.

[0052] The organic modifier is composed of fatty alcohol polyoxyethylene ether phosphate and tetrasodium edetate in a weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com